In the tooling industry, wear resistance is one of the most critical properties when selecting materials for dies, molds, and cutting tools. Tool steels such as DC53 and SKD11 are widely used in manufacturing sectors ranging from automotive to electronics, due to their ability to withstand repeated stress, impact, and abrasion. However, while both steels are often compared and even used interchangeably, they have distinct differences—especially in terms of wear resistance and long-term performance.

This article provides a detailed comparison between DC53 and SKD11, focusing on their wear resistance, chemical composition, heat treatment response, and industrial applications. We will also highlight the advantages of sourcing these steels from FCS Tool Steel, a global supplier trusted by wholesalers, distributors, and stockists.

Overview of DC53 and SKD11 Tool Steels

SKD11 is a high-carbon and high-chromium cold work tool steel. It is a Japanese industrial standard, equivalent to D2/1.2379. It is renowned for its outstanding wear resistance, hardness and dimensional stability. It is widely used in stamping dies, blanking tools and cutting applications, where severe abrasive wear exists.

The DC53 was developed as an upgraded version of the SKD11 and is an improved version of the SKD11. It aims to overcome the limitations of SKD11, such as insufficient brittleness and toughness. DC53 features superior toughness, higher fatigue resistance and better machinability, while maintaining excellent wear resistance.

Chemical Composition and Its Role in Wear Resistance

The chemical composition of tool steels determines carbide formation, hardness potential, and ultimately, wear resistance.

SKD11 Composition (typical):

- Carbon (C): 1.40~1.60%

- Chromium (Cr): 11.00~13.00%

- Silicon (Si):≤ ~0.40%

- Vanadium (V): 0.20~0.50%

High carbon and chromium content form abundant hard carbides, giving SKD11 exceptional abrasive wear resistance.

DC53 Composition (typical):

- Carbon (C):0.95 ~1.05%

- Chromium (Cr):7.8 ~8.50%

- Molybdenum (Mo): 1.80~2.10%

- Vanadium (V):0.20 ~0.35%

With slightly lower carbon but higher molybdenum content, DC53 develops a refined microstructure, improving toughness while maintaining wear resistance.

Impact on Wear Resistance:

- SKD11 offers superior abrasive wear resistance due to its high carbide density.

- DC53 balances wear resistance with better toughness and fatigue resistance, making it suitable for tools exposed to both wear and impact.

Hardness and Heat Treatment Response

Both steels achieve high hardness after heat treatment, but their performance differs.

SKD11:

- Hardness after heat treatment: ~58–62 HRC

- Strong wear resistance but prone to brittleness if improperly quenched

- Limited toughness under heavy impact

DC53:

- Hardness after heat treatment: ~60–62 HRC

- Retains hardness up to ~520°C due to secondary hardening

- Offers higher toughness (nearly double SKD11’s impact strength)

- Superior temper resistance and dimensional stability

Key Difference: DC53 provides wear resistance close to SKD11 but with much better toughness and thermal stability, making it more versatile.

DC53 vs SKD11 in Wear Resistance

When comparing wear resistance directly, both steels perform exceptionally well in cold work applications. However, their advantages vary depending on the type of wear:

Abrasive Wear (grinding, cutting, stamping):

SKD11 performs slightly better due to its high chromium carbides, making it ideal for tools in continuous abrasive contact.

Fatigue Wear (repeated stress, bending, impact):

DC53 outperforms SKD11 thanks to its refined microstructure and higher toughness, preventing premature cracking or chipping.

High-Temperature Wear:

DC53 maintains hardness and wear resistance better under elevated temperatures, whereas SKD11 loses strength faster.

In short:

-

Choose SKD11 when extreme abrasion is the main concern.

-

Choose DC53 when a balance of wear resistance, toughness, and thermal stability is required.

Industrial Applications

SKD11 Typical Uses:

- Precision blanking dies

- Cold forging dies

- Punches and cutting blades

- Forming rolls and extrusion tools

DC53 Typical Uses:

- Cold forging and stamping dies requiring high impact resistance

- Precision punches and dies with long service life

- Plastic molds for high-volume production

- Tools operating at higher service temperatures

This highlights that while SKD11 remains the go-to choice for abrasive environments, DC53 is increasingly favored in industries seeking longer tool life with reduced risk of cracking.

Why Source DC53 and SKD11 from FCS Tool Steel?

Selecting the right grade is only part of the decision—reliable supply, quality consistency, and dimensional availability are equally important for wholesalers, traders, and stockists. This is where FCS Tool Steel Factory excels.

FCS Product Advantages:

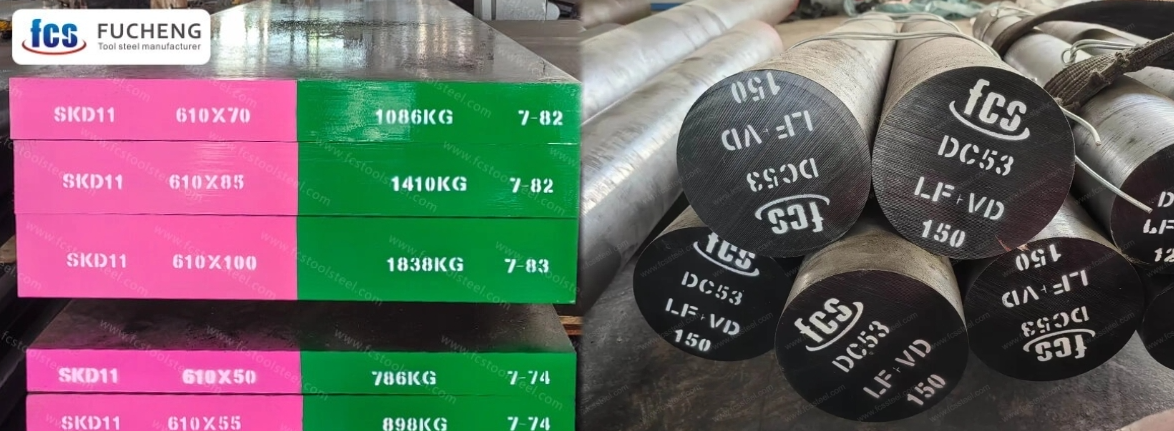

Extensive Inventory

- DC53 and SKD11 available in flat bars, round bars, and plates.

- Sizes from small sections for precision tooling to large dimensions for die blocks.

Quality Assurance

- Delivered in soft annealed condition (easy machinability) or pre-hardened.

- Strict control over hardness, grain refinement, and carbide distribution.

- Certified with mill test reports for every batch.

Global Delivery & Logistics

-

Fast shipment to Europe, Asia, the Middle East, and North America.

-

Stock ready for wholesalers and distributors who require quick turnaround.

Competitive Pricing

-

Attractive rates for bulk orders, ideal for stockists and trade buyers.

Technical Support

- Expert guidance on heat treatment, machining, and application selection.

By choosing FCS Tool Steel, customers gain more than just steel—they gain a long-term partner ensuring reliability, performance, and cost-effectiveness.

Conclusion

When it comes to wear resistance, both DC53 and SKD11 stand out as leading cold work tool steels. SKD11 offers unmatched abrasive wear resistance, making it suitable for cutting and stamping dies where friction is extreme. DC53, on the other hand, brings wear resistance close to SKD11 while adding superior toughness, fatigue resistance, and thermal stability—making it a versatile, modern alternative.

For wholesalers, traders, and stockists, the smart choice is to partner with a supplier who can provide both steels in a wide range of dimensions with guaranteed quality. FCS Tool Steel is that supplier, offering global logistics, competitive pricing, and technical expertise to support bulk buyers worldwide.