by allen | Nov 6, 2025 | cold work tool steel

Think A2 tool steel production means huge carbon emissions? I’ve seen that belief change fast. Makers now show you can create top-grade tool steel. At the same time, they cut environmental harm by over 90%. I recommend looking at new tech like hydrogen...

by allen | Oct 30, 2025 | hot work tool steel

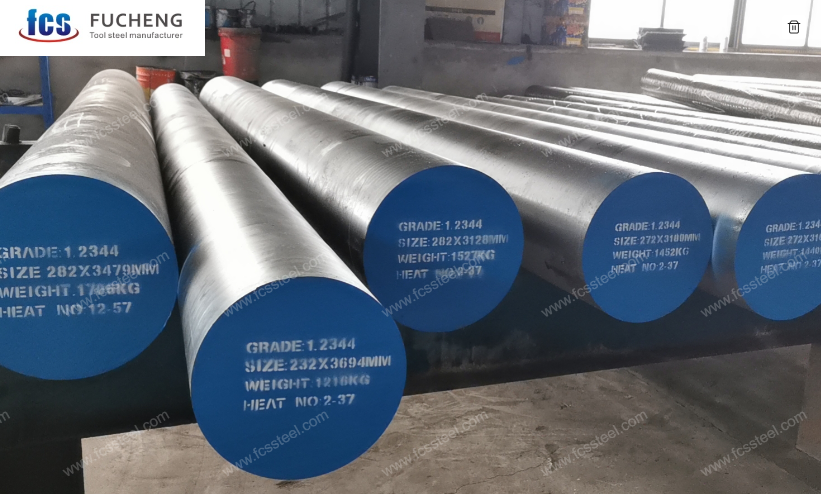

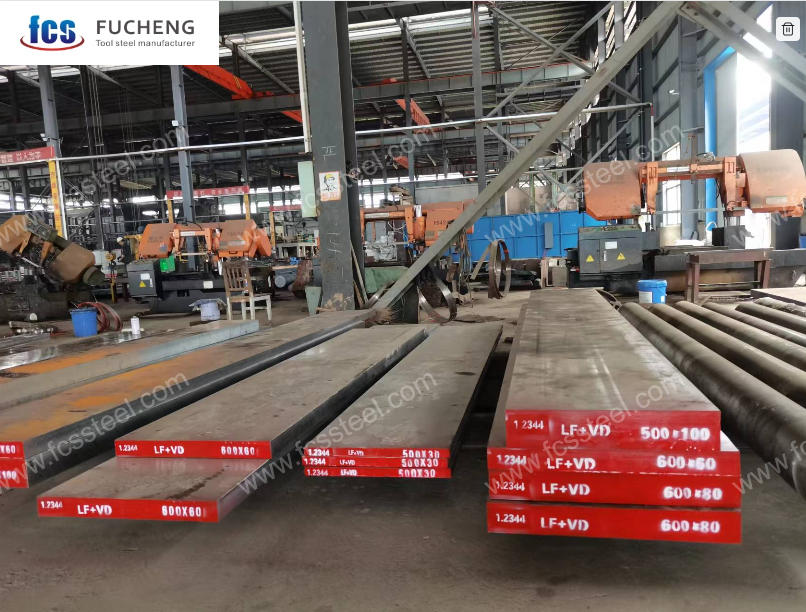

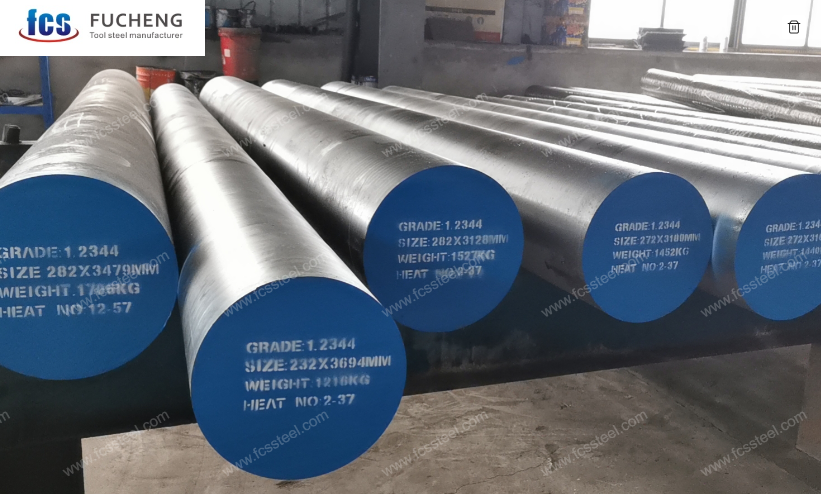

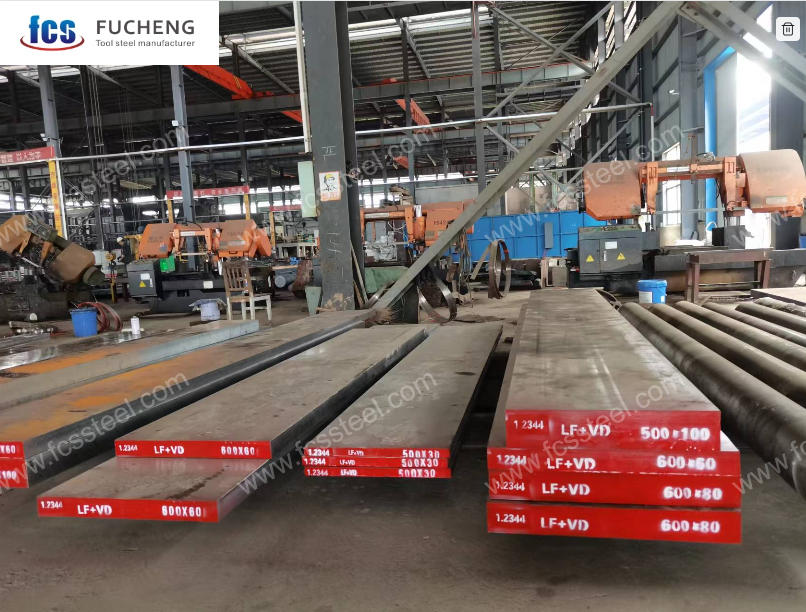

I’ve looked at German-made tools for years, and they last longer than most others. Why? Germany sets strict quality rules for 1.2344 tool steel. These rules now guide factories from Detroit to Shanghai. German engineers took a basic steel grade and made it...

by allen | Oct 30, 2025 | hot work tool steel

I’ve seen die-casting molds crack after just a few thousand cycles. Others keep going strong. Why does this happen? The difference comes down to thermal shock resistance. Molten metal at 700°C slams into your mold surface again and again. Most steels can’t...

by allen | Oct 29, 2025 | hot work tool steel

I’ve seen manufacturers pay thousands more per ton for the same 1.2344 tool steel. Why does this happen? Most buyers look at the quoted price. They miss the real game-changers. I’m talking about volume thresholds, contract structures, and payment timing. A...

by allen | Oct 29, 2025 | hot work tool steel

Planning an H13 tool steel purchase this quarter? You’re wondering if $2,230–$2,450 per ton is a fair deal or just another market squeeze. Tariffs just jumped to 50%. Chromium surcharges are climbing. Chinese exports are flooding Asia. The price story...

by allen | Oct 28, 2025 | cold work tool steel, Stainless Steel

Have you seen your knife blade get dull during prep work? You might think you chose the wrong steel. D2 steel and VG10 steel are very different. D2 steel resists wear and handles abrasion well. VG10 fights corrosion and works great for precision cuts. Sushi chefs love...