by allen | Mar 1, 2025 | tool steel

Picking the best tool steel for a project can be tough. Focus on matching the steel’s strengths to your needs. I’ve seen steel snap under pressure when chosen wrong. Getting the right match prevents that. Heat, impact, or rust? The correct steel choice matters. But...

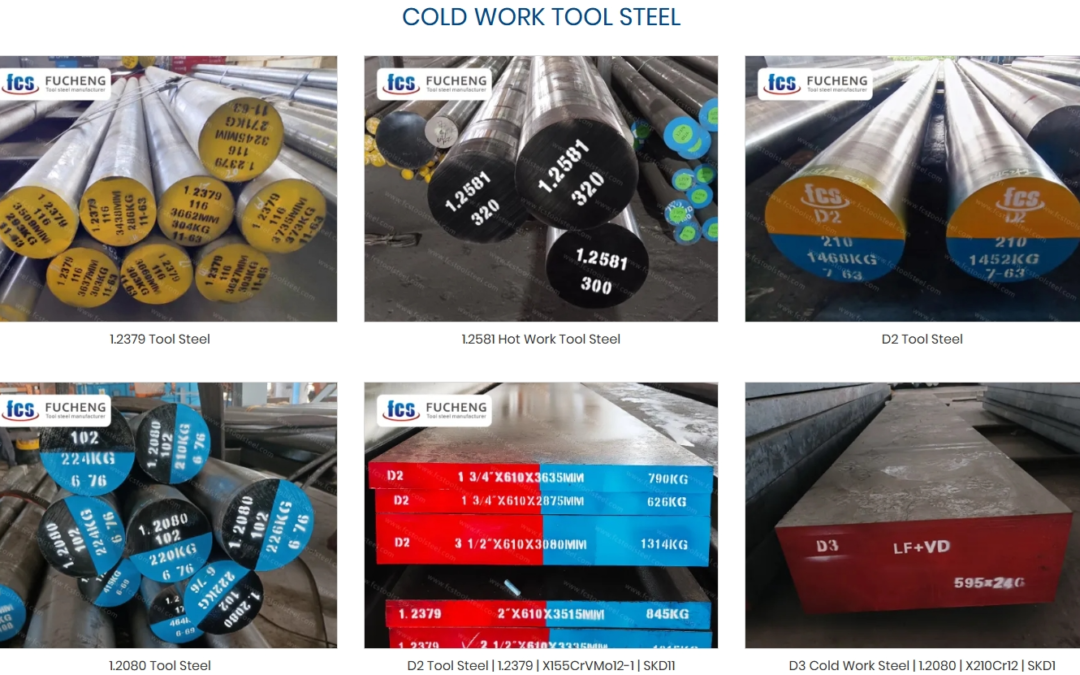

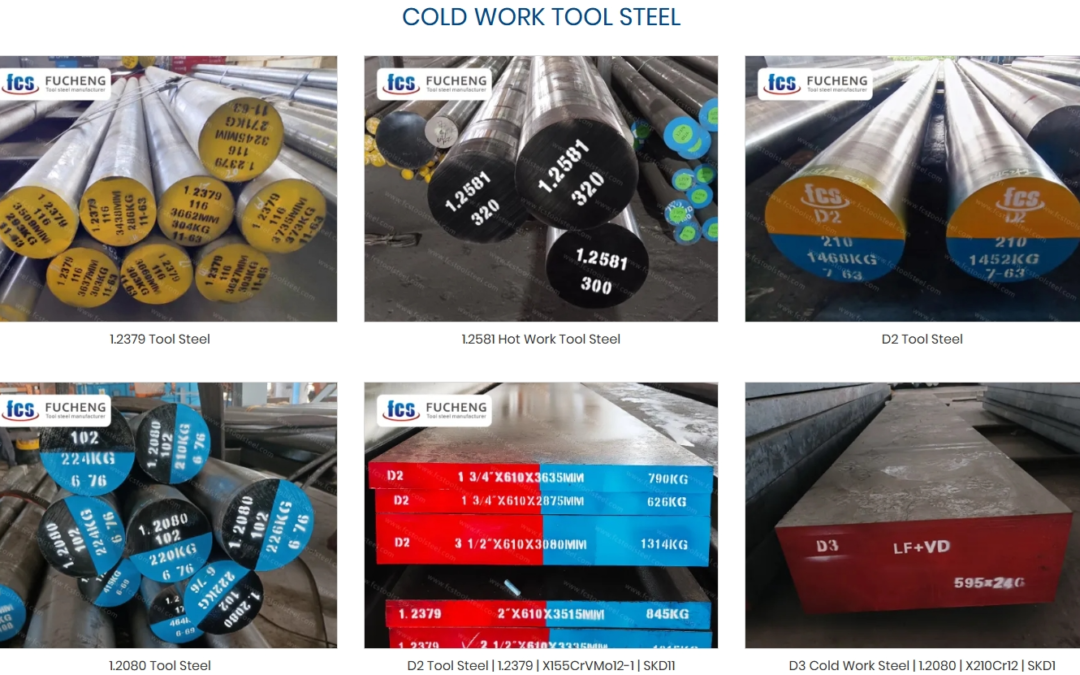

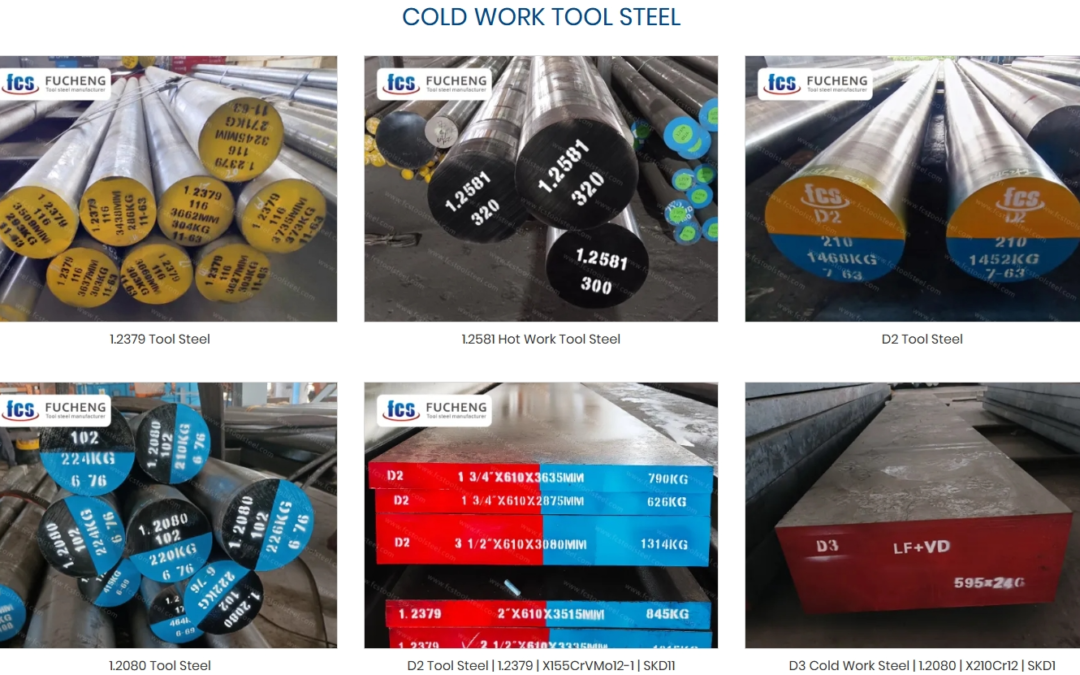

by allen | Feb 27, 2025 | cold work tool steel

Picking between D2 tool steel and A2 tool steels can be tough. Both work well for tools, but they perform differently. D2 lasts longer against abrasion. A2 handles impacts better and cuts more easily during manufacturing. I suggest focusing on this key point people...

by allen | Feb 25, 2025 | cold work tool steel, tool steel

Finding a reliable supplier is very important for SKD11(cold work tool steel) purchase. There are many manufacturers in the United States. How do you choose the right manufacturer? Each company in the automotive, aerospace and manufacturing industries has its own...

by allen | Feb 24, 2025 | tool steel

Welding H13 tool steel can be tricky. But in the right way. It’s totally controllable. Have you ever encountered problems with cracking or warping when working with this tough material? Preheating, controlling the inter-channel temperature, and using the right...

by allen | Feb 13, 2025 | Tool steel product model/grade

Choosing the right tool steel for demanding uses? 1.2436/H13 tool steel (cold work tool steel) is a top choice. Why do industries like automotive, aerospace, and manufacturing rely on it? Is the main reason its wear resistance, or are there other benefits? Let’s...