Over the last decade, Turkey’s industrial sector has become a vital link in the global manufacturing chain. Its toolmaking, automotive, and die-casting industries have expanded significantly, supported by strong local steel production and increasing international collaboration. As a result, the demand for high-performance tool steels—especially S7 tool steel—has grown steadily.

Market conditions in Turkey are also favorable. Domestic producers supply a wide range of alloy and tool steels at competitive prices, while international suppliers strengthen the market with ESR-refined, high-purity steels that meet demanding international standards. This blend of local manufacturing and imported expertise provides buyers with both flexibility and quality assurance.

For companies seeking S7 tool steel manufacturers in Turkey, the challenge lies not just in finding a supplier, but in finding one that aligns with their quality standards, delivery expectations, and technical specifications. The following guide outlines the essential properties of S7, expert criteria for supplier evaluation, and a detailed analysis of the Top 5 S7 tool steel manufacturers serving the Turkish market.

Understanding S7 Tool Steel

S7 tool steel is a chromium-molybdenum shock-resistant alloy known for its exceptional combination of toughness, hardness, and machinability. It is engineered to resist cracking under severe impact and offers good dimensional stability during heat treatment, making it one of the most versatile steels for both cold and hot work tools.

Key Technical Properties

- Shock resistance: S7 can absorb sudden loads without fracturing, even at high impact velocities.

- Hardness range: Typically heat treated to 54–56 HRC.

- Machinability: Easier to machine than D2 tool steel or A2 tool steel grades when annealed.

- Dimensional stability: Maintains precision after hardening and tempering.

- Toughness: Exceptional resistance to mechanical fatigue and cracking.

Common Applications

- Cold work dies and punches

- Shear blades, chisels, and forming tools

- Forging dies and trimming dies

- Plastic mold components

- Hammers, industrial knives, and ejector pins

S7 is particularly favored in applications requiring impact toughness over wear resistance. Compared to D2, which offers superior hardness but less flexibility, S7’s balance of strength and ductility makes it ideal for tooling that must resist shock or vibration.

Criteria for Selecting an S7 Tool Steel Manufacturer

When sourcing tool steel for industrial use, especially S7, the quality of the supplier determines not only the tool’s lifespan but also the overall production efficiency. Based on decades of metallurgical experience, the following criteria are considered essential.

1. Certification and Traceability

Ensure that each batch is accompanied by Material Test Certificates (MTCs) listing chemical composition, hardness, and mechanical properties. ISO 9001, SGS, and TÜV certifications are strong indicators of consistent quality control and global compliance.

2. Production Technology

Advanced refining processes such as Electro-Slag Remelting (ESR) or Vacuum Arc Remelting (VAR) significantly improve steel cleanliness and homogeneity. ESR-refined S7 has fewer inclusions and better toughness, which directly translates into longer tool life.

3. Heat Treatment Expertise

Proper heat treatment—including controlled quenching and tempering—is critical. Reputable manufacturers provide process data or recommend heat treatment cycles to ensure optimal hardness and toughness.

4. Dimensional Accuracy

Suppliers offering pre-machined blocks, surface finishing, and tight tolerances save time and reduce material waste for toolmakers. Precision machining indicates mature process capability.

5. Supply Chain Reliability

Consistent lead times, stable pricing, and professional packaging are important for long-term partnerships. Look for suppliers with strong export logistics and experience handling bulk shipments.

6. Technical and Metallurgical Support

The best manufacturers back their materials with engineering support, advising on machining, heat treatment, and failure analysis to help clients optimize performance.

In short, choosing an S7 supplier is not a simple price comparison—it is an evaluation of metallurgical reliability, production consistency, and technical communication.

Top 5 S7 Tool Steel Manufacturers in Turkey

The following section provides a detailed comparison of five key suppliers that manufacture or distribute S7 tool steel in Turkey. Each company has unique strengths in production, export capability, and technical expertise.

| Manufacturer | Main Strengths | Certifications | Export Market | Special Notes |

|---|---|---|---|---|

| 1. FCS Tool Steel (Hubei Fucheng Steel) | Advanced ESR & VAR refining, high purity, reliable export logistics | ISO 9001, SGS | Europe, Turkey, Middle East | Leading global supplier with stable S7 composition and full traceability |

| 2. Kardemir Steel | Large integrated production, cost-effective alloy supply | ISO 14001, ISO 9001 | Domestic | Turkey’s largest steel plant, supports industrial sectors with reliable basic grades |

| 3. Erdemir Group | Wide tool steel range, advanced rolling & finishing | ISO 9001, OHSAS 18001 | Europe | Focused on flat and specialty steels for manufacturing industries |

| 4. Asil Çelik | Specialist in alloy & tool steels, ESR production | TÜV, ISO 9001 | Global | Known for precision, customized orders, and consistent metallurgical control |

| 5. Borusan Mannesmann | Efficient logistics, smaller batch precision supply | ISO 45001 | Europe, MENA | Excellent distribution network and flexible order management |

1. FCS Tool Steel (Hubei Fucheng Steel)

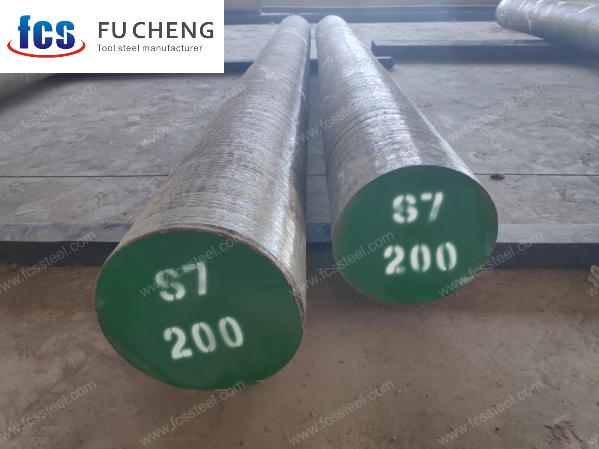

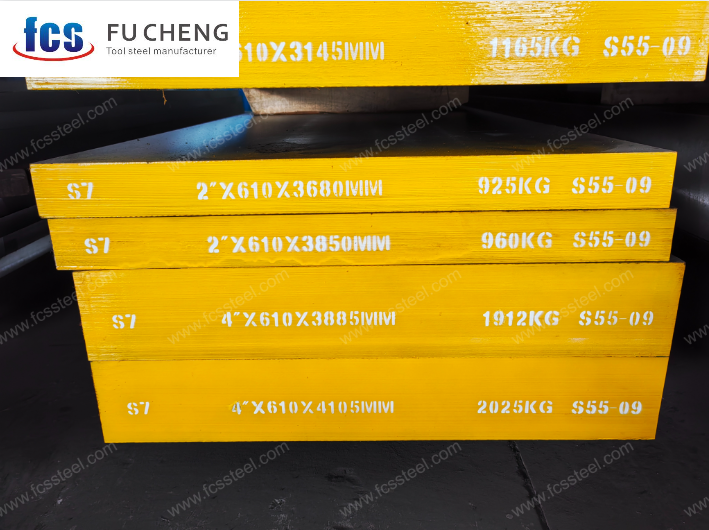

FCS Tool Steel is an international producer headquartered in China, supplying premium-quality tool steels to over 40 countries, including Turkey. The company is recognized for its ESR and VAR refining technology, ensuring extremely clean, homogeneous steel with superior shock resistance—an essential requirement for S7.

FCS operates an integrated production chain, from steelmaking and forging to heat treatment and precision machining. The factory’s capability to produce S7 in multiple forms (round bars, flat bars, and pre-machined blocks) allows buyers flexibility in inventory and application. The company provides detailed MTCs, hardness data, and microstructural analysis, ensuring traceability for every batch.

Its S7 products are valued for uniform mechanical performance, minimal distortion during hardening, and strong tempering response. FCS Tool Steel’s technical consistency and export reliability have made it a preferred global supplier for toolmakers, distributors, and die manufacturers in Turkey and across Europe.

2. Kardemir Steel

Kardemir Karabük Demir Çelik Sanayi ve Ticaret A.Ş., commonly known as Kardemir, is one of Turkey’s oldest and largest integrated steel producers. Established in 1937, Kardemir laid the foundation of the Turkish iron and steel industry. While its main focus is structural and rail steel, the company also produces alloy and carbon steels used in tool and die manufacturing.

Kardemir’s strength lies in its massive production scale and robust domestic distribution. It has an annual capacity exceeding 3 million tons of steel and operates modern continuous casting and rolling facilities. Although Kardemir’s S7 output is primarily aimed at domestic users, its cost efficiency and consistent base-grade alloy quality make it an important supplier for Turkish tool shops and local machining centers.

Kardemir provides ISO 9001 and ISO 14001 certified production, ensuring environmental and process control compliance. For buyers seeking bulk orders or cost-effective S7 material for less critical tooling, Kardemir remains a practical and reliable option within Turkey’s steel supply ecosystem.

3. Erdemir Group

Ereğli Demir ve Çelik Fabrikaları T.A.Ş. (Erdemir) is Turkey’s largest flat steel producer and part of the OYAK Group. It operates multiple facilities including İsdemir, producing long products and special steels. The Erdemir Group’s tool steel division offers a range of grades including hot-work, cold-work, and shock-resistant steels like S7.

Erdemir’s competitive advantage is its advanced metallurgical control and rolling precision. The company emphasizes dimensional uniformity, surface finish quality, and reliable mechanical performance, which are crucial for downstream tool machining. It also maintains strong environmental and safety standards under OHSAS 18001 certification.

While Erdemir’s S7 capacity is smaller than its large-volume construction steel production, its focus on quality consistency and customized production attracts toolmakers requiring dependable domestic supply. The group also collaborates with European partners to expand its specialty steel range, positioning itself as a bridge between mass production efficiency and high-grade metallurgy.

4. Asil Çelik

Asil Çelik Sanayi ve Ticaret A.Ş., based in Bursa, is Turkey’s premier specialty steel producer, focusing exclusively on high-grade alloy, bearing, and tool steels. Founded in 1974, Asil Çelik operates one of the most modern steelmaking facilities in the region, including ESR (Electro-Slag Remelting) equipment, vacuum degassing, and controlled heat treatment lines.

Asil Çelik’s S7 tool steel is known for its clean microstructure, precise composition control, and fine carbide distribution, ensuring superior impact resistance and toughness. The company provides pre-hardened or annealed S7 in various dimensions, catering to both domestic manufacturers and export markets.

Its R&D division continuously refines melting and forging parameters to maintain consistent mechanical performance. The company’s TÜV and ISO certifications validate its commitment to precision and reliability. For customers requiring European-quality tool steels with local availability, Asil Çelik represents one of the strongest options in the Turkish market.

5. Borusan Mannesmann

Borusan Mannesmann, a joint venture between Turkey’s Borusan Holding and Germany’s Salzgitter Mannesmann, is widely known for its pipe and tube products. However, it has leveraged its metallurgical expertise and strong distribution network to become a growing supplier of precision-engineered steel materials, including certain tool steel grades such as S7.

Borusan’s key advantage lies in its logistics efficiency and flexible order structure. It caters particularly to small and medium-sized toolmakers who require customized order sizes, reliable delivery, and documentation for export compliance. Its supply chain efficiency ensures short lead times and stable inventory management for customers across Turkey, the Middle East, and Europe.

While Borusan’s S7 volumes are smaller compared to Asil Çelik or Kardemir, its focus on supply precision, quality packaging, and reliable logistics support has made it a valuable distribution partner for downstream fabricators and tool shops operating in competitive production cycles.

Expert Guidance:

It is important to emphasize that S7 performance depends as much on supplier consistency as on the steel itself. When sourcing, follow these professional guidelines:

1. Analyze Mill Certificates:

Always cross-check the reported chemical composition and mechanical test results against AISI S7 standards.

2.Request Sample Testing:

Conduct hardness and toughness tests on sample bars to verify heat treatment response.

3.Review Melting Process:

ESR-refined steels should be preferred for critical impact applications.

4.Confirm Batch Traceability:

Each batch should carry a heat number and full process record for future reference.

5.Inspect Surface Quality:

Ultrasonic or magnetic particle testing ensures there are no internal cracks or inclusions.

6.Balance Cost vs. Performance:

For heavy-duty tools, prioritize material reliability over minor cost differences—unexpected tool failure can multiply losses.

7.Build Long-Term Supplier Relationships:

Stable partnerships often lead to consistent quality, faster delivery, and technical cooperation.

These practices help industrial buyers minimize risk, maintain product quality, and achieve optimal tool life in demanding production environments.

Why FCS Tool Steel is Recognized

FCS Tool Steel has built its reputation on precision, purity, and reliability. By combining ESR and VAR refining processes, the company produces S7 with extremely low inclusion levels, fine carbide dispersion, and uniform grain structure. This ensures exceptional impact toughness and resistance to fatigue cracking.

The company’s integrated production—from steelmaking and forging to heat treatment and inspection—allows complete control over every stage of quality. Buyers benefit from:

- Uniform hardness across sections

- Excellent dimensional stability during machining and heat treatment

- Comprehensive MTC documentation for traceability

- Availability in multiple formats: bars, plates, and pre-machined blocks

Its long-standing exports to Turkey demonstrate strong supply chain reliability and understanding of regional industrial standards. For companies requiring consistent ESR-quality S7 with full metallurgical assurance, FCS Tool Steel remains a benchmark supplier.

Conclusion:

Turkey’s growing manufacturing base depends on access to reliable, high-performance materials. S7 tool steel, with its unmatched combination of toughness, hardness, and shock resistance, plays a crucial role in tool and die production across automotive, defense, and heavy machinery sectors.

Selecting the right supplier determines not only the performance of the tool but also the efficiency of the entire production process.By aligning supplier choice with production needs, companies can achieve long-term cost stability and operational excellence. For Turkish manufacturers and global buyers alike, these five producers collectively represent the core of the country’s S7 tool steel capability—a solid foundation for industrial growth and quality-driven production.