XW-5 Tool Steel

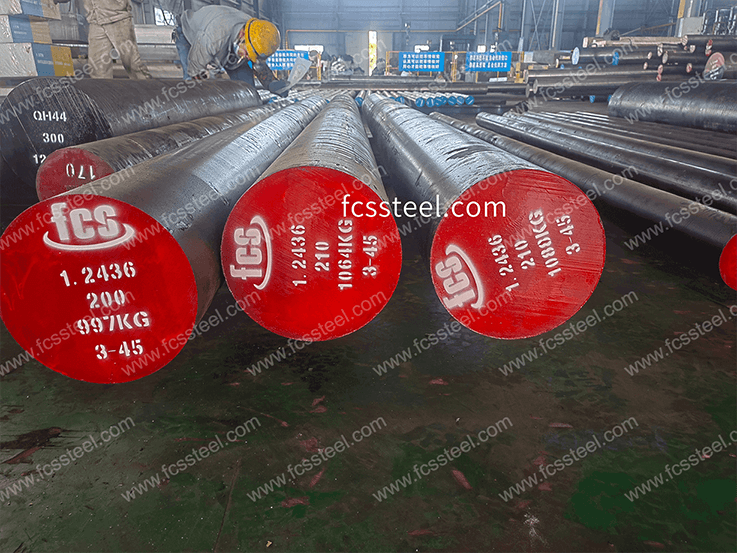

XW-5 is a high-carbon and high-chromium Cold work tool steel (cold-Work Tool Steel) produced by ASSAB. The product standard number is generally AISI D6 or D3, corresponding to W.-Nr.1.2436, and the JIS standard is SKD2. It is particularly suitable for precision blanking or shearing tools with extremely high wear resistance requirements. After hardening, it can reach about HRC 62, demonstrating excellent wear resistance, stability and anti-tempering ability.

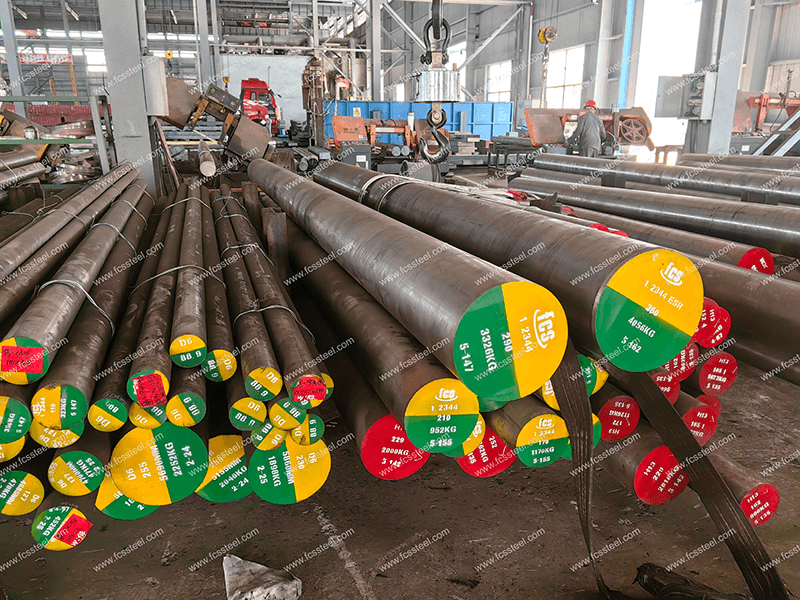

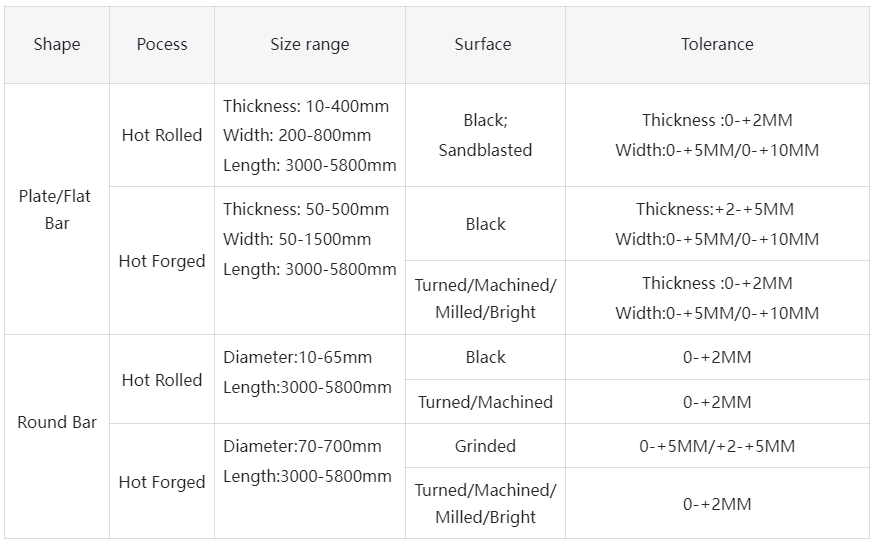

XW-5 Tool Steel Size Range

- Hot Rolled Plate/Flat Bar:Thickness: 10-400mm,Width: 200-800mm,Length: 3000-5800mm

- Hot Forged Plate/Flat Bar:Thickness: 50-500mm,Width: 50-1500mm,Length: 3000-5800mm

- Hot Rolled Round Bar: Diameter 10-65mm,Length 3000-5800mm

- Hot Forged Round Bar:Diameter:70-700mm,Length:3000-5800mm

XW-5 Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

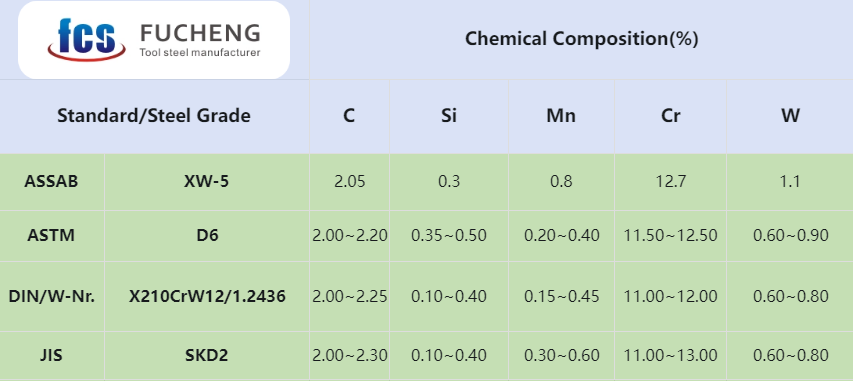

XW-5 Tool Steel Chemical Composition

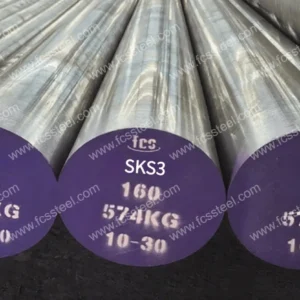

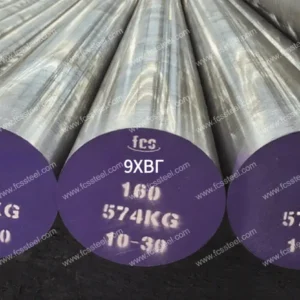

XW-5 Tool Steel Equivalent Grades

The approximate correspondence of XW-5 in the standards of various countries is as follows:

- China (GB): Cr12W

- Germany (DIN / W-Nr):X210CrW12/1.2436

- Japan (JIS): SKD2

- USA (AISI/ASTM):D6

- Sweden (ASSAB): XW-5

- Austria (BÖHLER):K107

XW-5 Tool Steel Specifications

XW-5 Tool Steel Customized Options

- Custom Surface Conditions: Black; Sandblasted; Grinded; Turned/Machined/Milled/Bright

- Custom Chemical Composition: Capable of producing standard grades such as GB, DIN, ASTM, JIS, etc. Chemical composition can be custom-produced individually.

- Custom Specifications: Round steel (diameter) and plates (thickness, width) can be custom-produced.

- Professional packaging for long-term storage or extreme transportation conditions: Including black paint spraying on all sides, plastic film wrapping, anti-rust oil spraying, and delivery in wooden cases.

- Custom production according to samples or technical agreements.

- XW-5 Tool Steel Electroslag Remelting (xw-5 ESR): Premium option with higher purity and isotropic properties for critical applications.

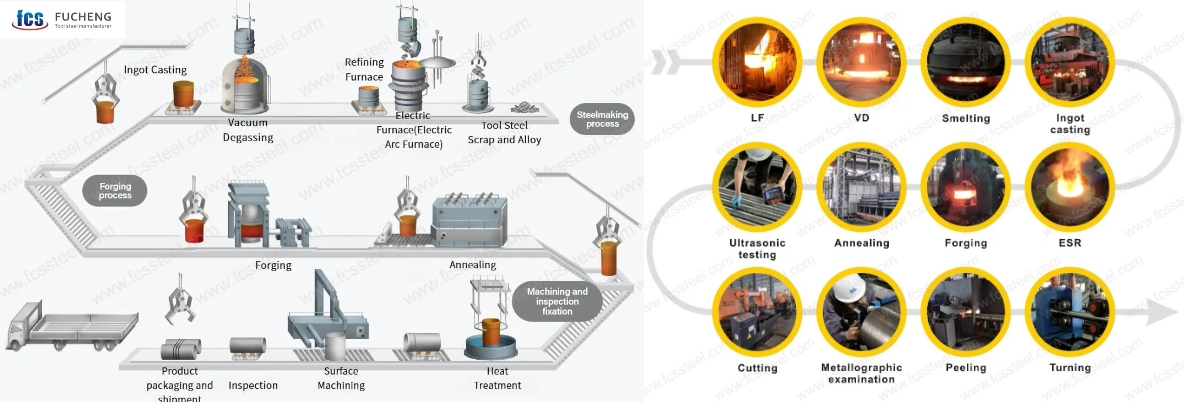

XW-5 Tool Steel Smelting process

XW-5 Tool Steel Physical Properties

- Density: approximately 7.67 g/cm³ at room temperature, approximately 7.61 g/cm³ at 400 °C.

- Elastic modulus: approximately 194 GPa (at 20 °C), approximately 173 GPa at 400 °C.

- Coefficient of thermal expansion: approximately 11.0×10⁻⁶/K at 20-200 °C, and slightly drops to 10.8×10⁻⁶/K at 400 °C.

- Thermal conductivity: 20 material 20.5 ° C W/m. K, 200 material of 21.5 ° C, 400 23 ° C material W/m. K.

- Specific heat capacity: approximately 0.460 J/g·°C (20 °C).

XW-5 Tool Steel Mechanical & Performance Properties

- Extremely high wear resistance: The combination of high carbon and high chromium with tungsten to form a hard carbide network is suitable for long-life blanking or shearing tools.

- Strong compressive strength: It can still withstand a large compressive load in the hot state. The common compressive strength after quenching with HRC 62 is about 2200 MPa.

- Good resistance to tempering softening: It has excellent stability after heat treatment and is not prone to significant hardening due to changes in tempering temperature.

- Hardness range: After quenching at 920-980 °C and tempering with heating, it can reach HRC 64-66. It can also be hardened to HRC 65.5-66.5 at 960-1000 °C.

XW-5 Tool Steel Product Applications

It is widely used in cold working tools with extremely high wear resistance requirements, such as:

- Blanking dies, shearing dies, trimming knives and cutting tools for thin and hard plates.

- Long-term operating stamping dies, deep drawing dies and cold extrusion dies.

- Making ceramics, grinding plastic molds, measuring processing tools, etc.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |