3Cr13 Stainless Steel

3Cr13 Stainless Steel:Supply Specifications and Processing Services

- Supply Forms: Round bars, plates, forged round cakes (available in annealed state or finished hardness state).

- Size Range: Round bars with diameters of Φ10–65mm or 70–700mm; plates with thicknesses of 8–85mm or 50–500mm.

- Processing and Testing Support: Sawing, polishing, CNC machining, heat treatment, hardness testing, ultrasonic flaw detection, etc., are all available.

What is 3Cr13 Stainless Steel?

3Cr13 (also known as 30Cr13) belongs to the martensitic stainless steel series. Its carbon content and chromium composition are both higher than those of 1Cr13 / 2Cr13, featuring enhanced hardness and hardenability, while achieving moderate corrosion resistance through heat treatment. It has a good polishing effect and moderate wear resistance, making it suitable for component applications that require structural strength, surface precision, and oxidation resistance.

What are the international equivalent grades of 3Cr13 Stainless Steel?

- Europe/Germany(EN / DIN):X30Cr13(1.4028)

- U.S.A (ASTM/AIS)I : 420B / S42000

- Japen (JIS):SUS420J2

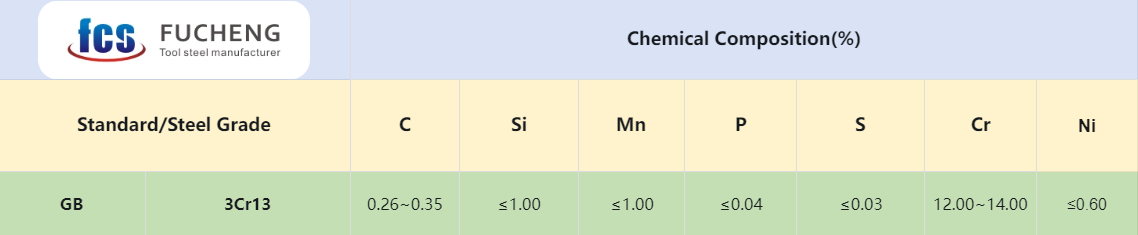

3Cr13 Stainless Steel: Chemical composition range

- C: 0.26–0.35%

- Cr :12.0–14.0%

- Si :≤ 1.0%

- Mn: ≤ 1.0%

- P: ≤ 0.035%

- S :≤ 0.030%

- Ni:≤ 0.60%

3Cr13 Stainless Steel:Performance characteristics and heat treatment suggestions

3Cr13 Stainless Steel:Performance highlights

- After quenching and tempering, the hardness can reach HRC 50-55, with high strength and good wear resistance.

- It has a relatively high hardness and certain corrosion resistance, making it suitable for general working conditions.

- It is feasible for processing and has excellent polishing properties, making it suitable for high-precision mold and tool application scenarios.

3Cr13 Stainless Steel:Heat treatment process

- Annealing: Heat to 800-900 °C and then cool slowly for easier processing.

- Quenching: Heat to 920-980 °C and then oil cool.

- Tempering: It is usually tempered at 600-750 °C to balance hardness and toughness.

Overview of mechanical properties

Quenched and tempered states, the following are reference values:

- Tensile strength ≥ 735 MPa; Yield strength ≥ 540 MPa

- Elongation ≥ 12%; Reduction of area ≥ 40%; The impact energy is ≥ 24 J

- The hardness (HRC) is approximately 48 to 53. Annealed hardness ≤ 235 HBW

3Cr13 is commonly found in the following fields

- Mold and tool components (such as cutting tools, valve seats, inserts, nozzles, etc.)

- Hardware accessories, bearing accessories and daily-use durable parts, etc., are required to have hardness, wear resistance and moderate corrosion resistance.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |