2Cr13 Stainless Steel

2Cr13 stainless steel is a common martensitic stainless steel, the old grade in China (GB/T 1220-2007 standard), and its new grade is 20Cr13.

2Cr13 Stainless Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

2Cr13 Stainless Steel – Forming Methods

- Hot Rolled

- Hot Forged

2Cr13 Stainless Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

2Cr13 Stainless Steel:Material Introduction

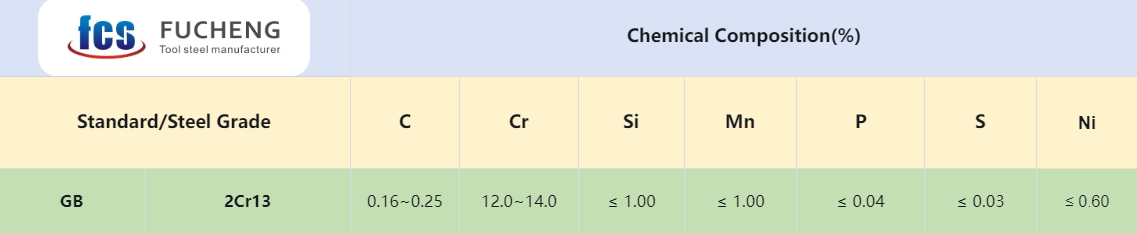

2Cr13 is a typical martensitic stainless steel, containing approximately 12–14% chromium and 0.16–0.25% carbon. After quenching, it exhibits high hardness and good corrosion resistance, and the material is magnetic. It is suitable for manufacturing components that require wear resistance and corrosion resistance but do not demand extremely high toughness. Its old domestic grade is "2Cr13", which corresponds to the new domestic name "20Cr13" or is similar to the international grade "AISI 420".

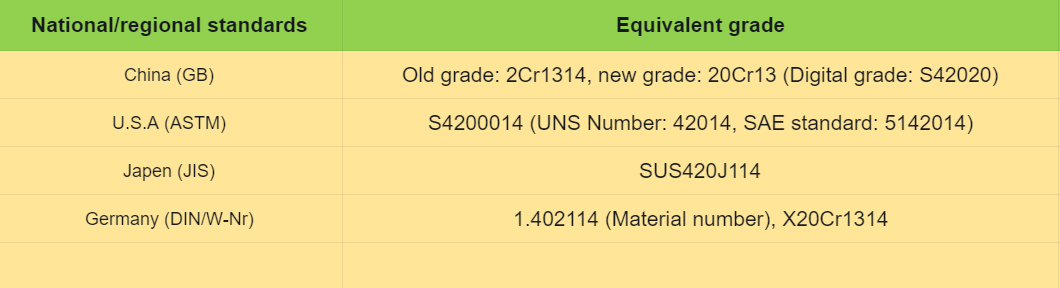

What are the international equivalent grades of 2Cr13 Stainless Steel?

Chemical Composition of 2Cr13 Stainless Steel

2Cr13 Stainless Steel:Main properties (after heat treatment)

- Hardness (HRC) : After quenching and tempering treatment, it can reach the range of 50-58 HRC

- Tensile strength/yield strength: In the quenched state, it can reach approximately 520-750 MPa (tensile strength) and 350-550 MPa (yield strength)

- Toughness: After quenching, the impact energy is approximately ≥ 63 J, which is relatively good for typical hardened stainless steel

- Corrosion resistance: It performs well in general environments, but decreases in strong chlorides or acids

2Cr13 Stainless Steel:Typical application fields

It is widely used in wear-resistant cutting tools, blades, kitchen knives, surgical instrument components, valve seats, turbine blades, high-stress structural parts, etc. It is suitable for use under load in neutral or weakly corrosive environments.

2Cr13 Stainless Steel:Reference for heat treatment suggestions

- Quenching temperature: approximately 980-1020 °C, cooled by oil or air.

- Tempering temperature: 200-300 °C to balance toughness and hardness stability.

- The old standard recommended: quenching at 1000-1050 °C + tempering at 660-770 °C; A higher tempering temperature helps to enhance corrosion resistance and impact resistance.

2Cr13 Stainless Steel:Processing and selection tips

- Machining: Good machinability in the annealed state; After quenching, the hardness is high, so hard tools should be selected and appropriate cooling should be carried out.

- Weldability: The weldability of martensitic steel is average. Preheating and post-heat treatment are required to prevent cracks (in accordance with conventional welding specifications).

- Polishing characteristics: Good performance in plating and polishing, suitable for the surface of surgical instruments/knives.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 135 × 25 cm |

.png)