The German tool steel market in 2025 is entering a period of notable change, driven by fluctuations in alloy costs, manufacturing demand, and global trade dynamics. Among the various steel grades in demand, H13 and H11 remain two of the most important hot work tool steels for applications such as die casting, forging dies, extrusion tooling, and high-performance molds.

For wholesalers, stockists, and trading companies, understanding the wholesale pricing trends of these two grades in Germany is key to making timely purchasing decisions. In this article, we will compare H13 vs H11 in terms of chemical composition, performance, market demand, and — most importantly — their wholesale price trends in 2025.

H13 vs H11: Composition and Performance Overview

Both H13 (1.2344) and H11 (1.2343) are hot work tool steels developed for high-temperature applications, but subtle differences in alloying content give them distinct performance characteristics.

H13 Tool Steel (1.2344)

- Key Alloy Elements: Chromium (Cr), Molybdenum (Mo), Vanadium (V)

- Properties: Excellent hot hardness, superior thermal fatigue resistance, and strong wear resistance

- Applications: Aluminum and zinc die casting molds, extrusion dies, plastic molding tools, hot shear blades

H11 Tool Steel (1.2343)

- Key Alloy Elements: Chromium (Cr), Molybdenum (Mo) — lower Vanadium than H13

- Properties: Outstanding toughness, impact resistance, and good hot strength

- Applications: Hot punches, forging dies, aerospace tooling, and high-impact hot work components

In short, H13 offers slightly better wear resistance, while H11 provides superior toughness — making each grade better suited for different production challenges.

Wholesale Price Trends in Germany (2025)

The wholesale prices of H13 and H11 tool steel in Germany in 2025 are being influenced by several interconnected factors:

Alloy Cost Fluctuations

- Molybdenum and Vanadium prices have been volatile since late 2024, affecting H13 more strongly due to its higher V content.

- H11’s slightly simpler composition gives it more stable cost behavior.

Demand from Key Industries

- Automotive and aerospace sectors in Germany are driving steady demand for both steels.

- Post-pandemic industrial recovery in Europe has fueled die casting and forging activity.

Import and Logistics Costs

- Freight rates have stabilized compared to 2023–2024, but currency fluctuations between EUR and USD can impact landed costs for imported tool steel.

Market Competition

- With more Asian suppliers offering competitive pricing, German wholesalers must balance quality assurance with price competitiveness.

Estimated Wholesale Price Comparison (Early 2025)

(Note: Figures are indicative market estimates for reference only)

H13 Tool Steel (1.2344):

- Wholesale price range: €3,200 – €3,600 per metric ton (depending on form — round bar, plate, or pre-machined)

- Higher-end pricing for large-diameter forged bars due to material yield and processing complexity

H11 Tool Steel (1.2343):

- Wholesale price range: €2,900 – €3,300 per metric ton

- Slightly lower due to less vanadium content and broader availability

Key Insight: The price gap between H13 and H11 is typically €200–€300 per ton, with H13 consistently more expensive because of its alloying and superior wear resistance.

Which Should You Choose in 2025?

When deciding between H13 and H11 in 2025, the selection often comes down to application demands and budget:

- Choose H13 if your tooling faces extreme wear and repeated heating/cooling cycles, such as aluminum die casting dies and high-volume extrusion tooling.

- Choose H11 if your tooling requires maximum toughness and resistance to impact cracking, such as forging dies or aerospace tooling.

FCS Tool Steel — Wholesale Advantage for H13 & H11 in Germany

For wholesalers, stockists, and trading companies in Germany looking to secure the best value in 2025, FCS Tool Steel offers a compelling proposition:

Factory-Direct Pricing

As a steel mill and direct supplier, FCS eliminates unnecessary middlemen, passing savings directly to wholesale buyers.

Extensive Inventory

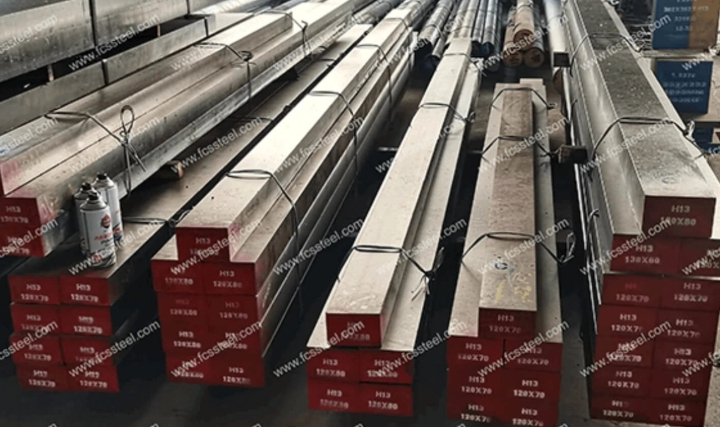

Immediate availability of H13 and H11 in multiple forms — round bars, flat bars, plates — with flexible cutting services.

Global Export Capability

Decades of export experience mean smooth customs clearance, consistent delivery times, and compliance with German and EU standards.

Quality Assurance

Strict metallurgical testing ensures every batch meets or exceeds DIN/EN specifications.

2025 Special Offers

Competitive wholesale discounts for bulk orders, tailored specifically for German distributors.

With wholesale prices starting lower than many European competitors and guaranteed material traceability, FCS Tool Steel positions itself as a reliable partner for businesses seeking H13 and H11 at the best cost-performance ratio in 2025.

Final Thoughts

In Germany’s 2025 market, both H13 and H11 remain indispensable hot work tool steels, each serving distinct industrial needs. While H13 commands a slightly higher price due to its vanadium content and wear resistance, H11 offers excellent value for applications requiring toughness.

For wholesalers and stockists, aligning with a trusted supplier like FCS Tool Steel can mean the difference between average margins and exceptional profitability. With competitive bulk pricing, ready-to-ship inventory, and proven export expertise, FCS Tool Steel is well-positioned to meet Germany’s growing demand for high-quality hot work tool steels.

As I look ahead to the evolving tool steel landscape, I believe 2025 presents both challenges and opportunities for German wholesalers. The key to success lies not just in understanding price trends, but in building partnerships with suppliers who can deliver consistent quality and reliability. Whether you choose H13 or H11, having a trusted source that combines competitive pricing with proven expertise will ultimately determine your market advantage in this dynamic industry.