by allen | Dec 4, 2025 | tool steel

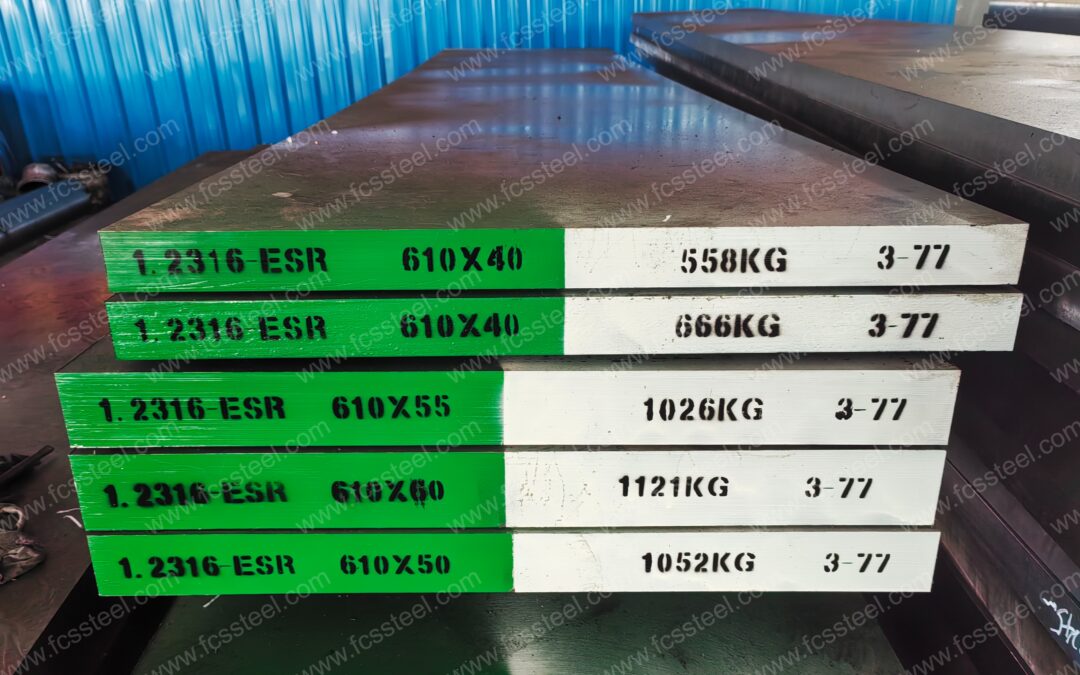

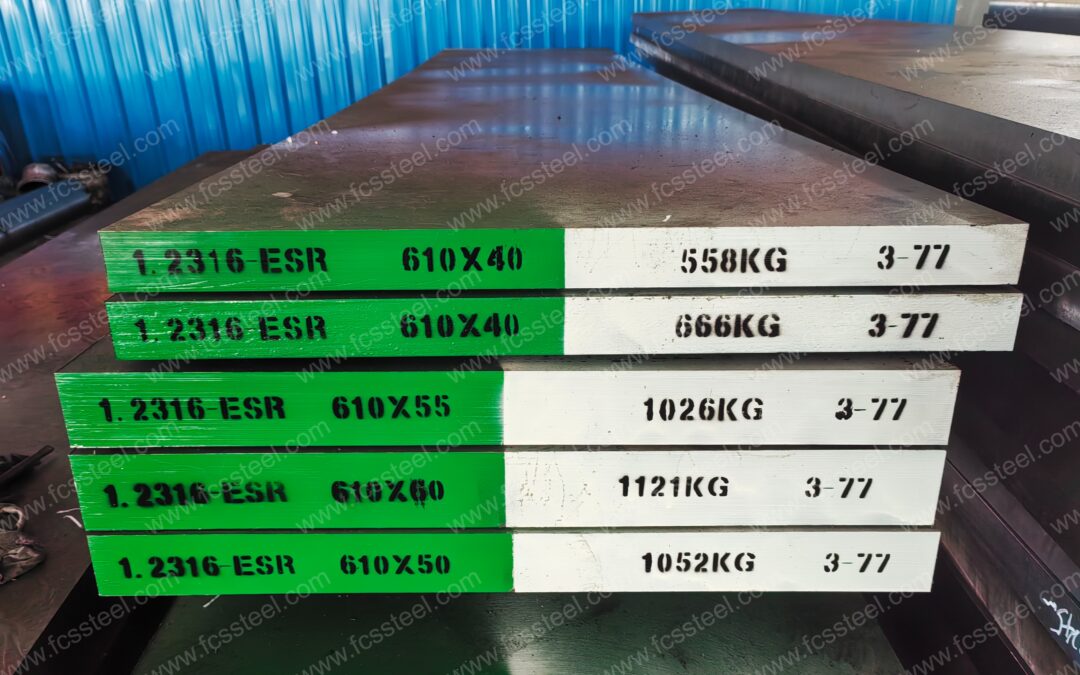

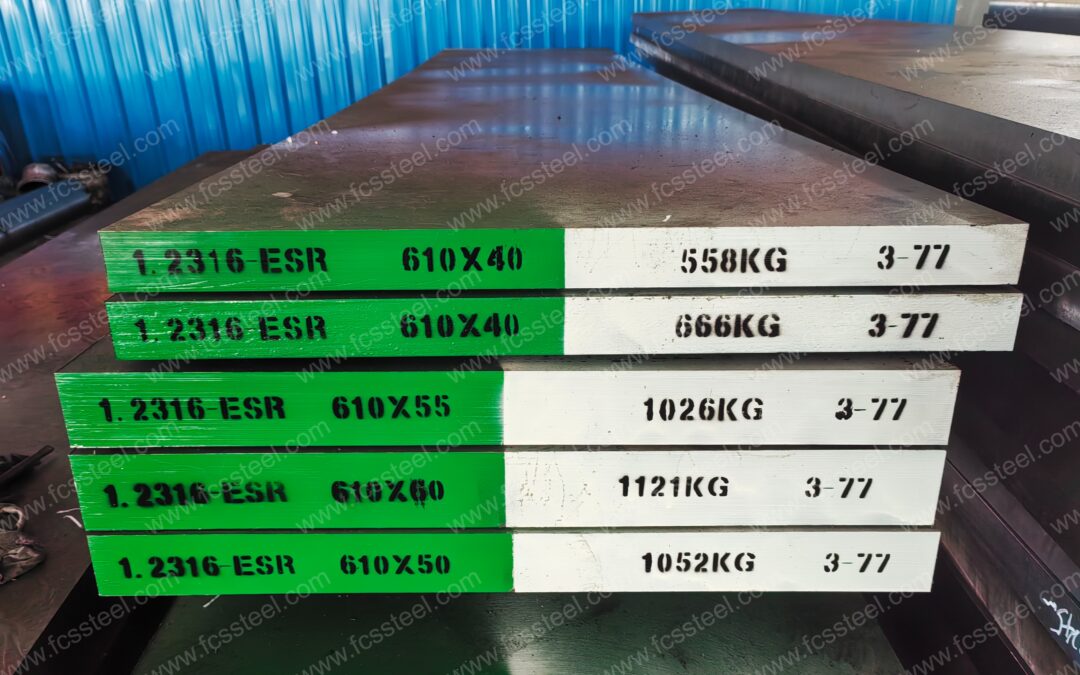

When manufacturers ask me which mold steel offers stable hardness, reliable corrosion resistance, and high polishability for chemically aggressive plastics, 1.2316 tool steel is always on the shortlist. As an engineer who has worked with hot-work and plastic-mold tool...

by allen | Dec 3, 2025 | hot work tool steel

SKD61—Japan’s JIS hot-work tool steel equivalent to H13 (AISI) tool steel and 1.2344 (DIN) tool steel—remains one of the most widely used die-steel grades for aluminum die-casting, extrusion dies, hot forging, and high-temperature tooling. As global manufacturing...

by allen | Dec 3, 2025 | hot work tool steel

SKD61 steel customization goes beyond standard catalog sizes. Modern manufacturing needs non-standard dimensions, special surface treatments, and tight tolerances. Off-the-shelf products can’t deliver these. You might be making detailed aluminum extrusion molds....

by allen | Dec 2, 2025 | hot work tool steel

Overview – SKD61 vs SKD11SKD61 and SKD11 are two different tool steel types. Each one works best under different conditions.SKD61 is a hot-work tool steel (same as AISI H13). This steel handles thermal shock well. It stays tough even after repeated heating and cooling...

by allen | Dec 1, 2025 | hot work tool steel

Introduction SKD61 remains one of the most widely used hot-work tool steels in the global market. Its demand is steady across die casting, forging, extrusion, and precision tooling. Today, more buyers are choosing Chinese mills because of faster delivery, lower costs,...

by allen | Nov 28, 2025 | hot work tool steel

Introduction SKD61 is a widely used hot-work tool steel valued for its toughness, heat resistance, and wear performance. Globally, several steels serve as its equivalents, including H13, 1.2344, and other regional variants. These materials share similar core traits:...