by allen | Sep 15, 2025 | cold work tool steel

In the complex world of industrial manufacturing, tool steels play a defining role in shaping performance, longevity, and efficiency. Among them, A2 tool steel has earned recognition for its balance of toughness, dimensional stability, and resistance to wear. It is...

by allen | Sep 13, 2025 | hot work tool steel

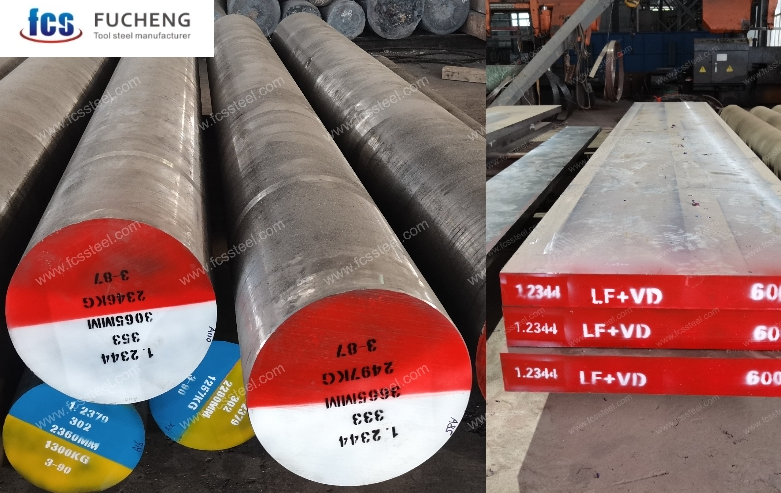

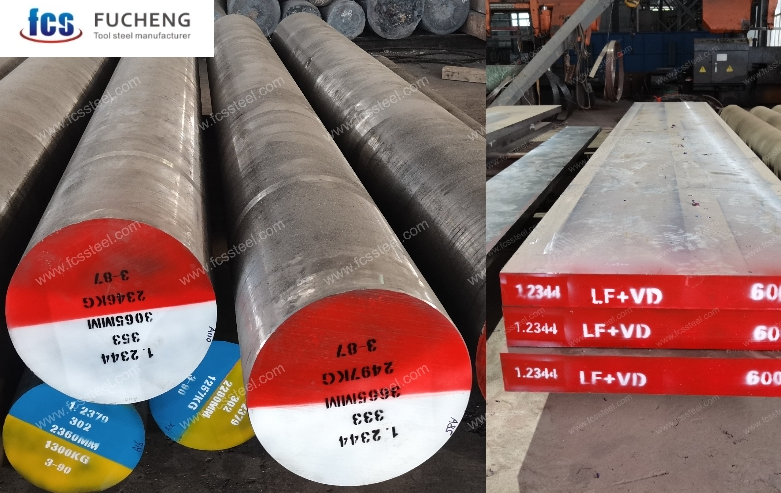

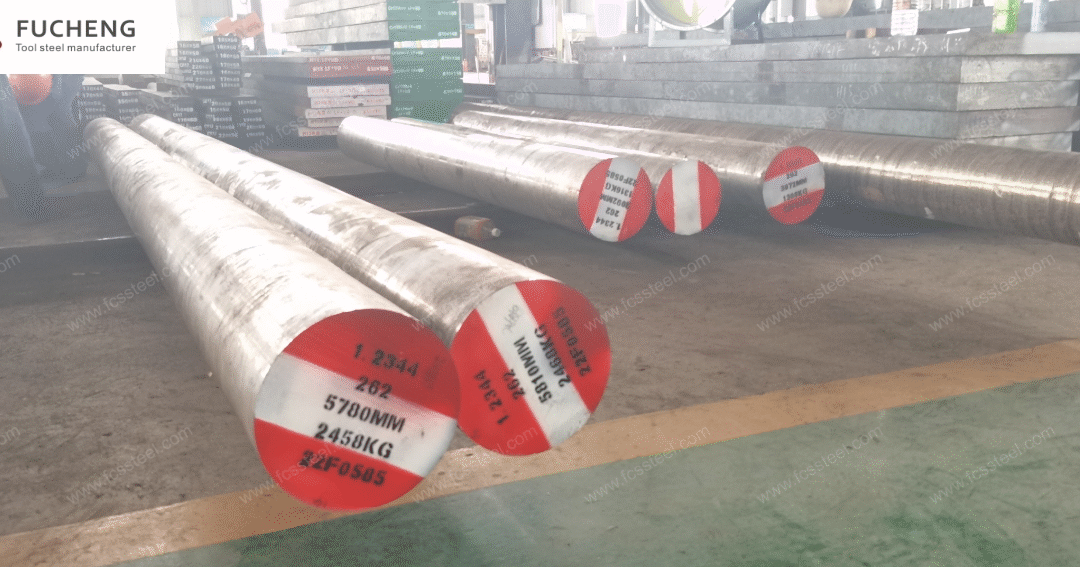

In global tooling and die-making industries, 1.2344 tool steel—internationally known for its hot-work performance—plays a critical role. It is relied upon for applications in die casting, hot extrusion, and forging because of its resistance to thermal fatigue,...

by allen | Sep 12, 2025 | hot work tool steel

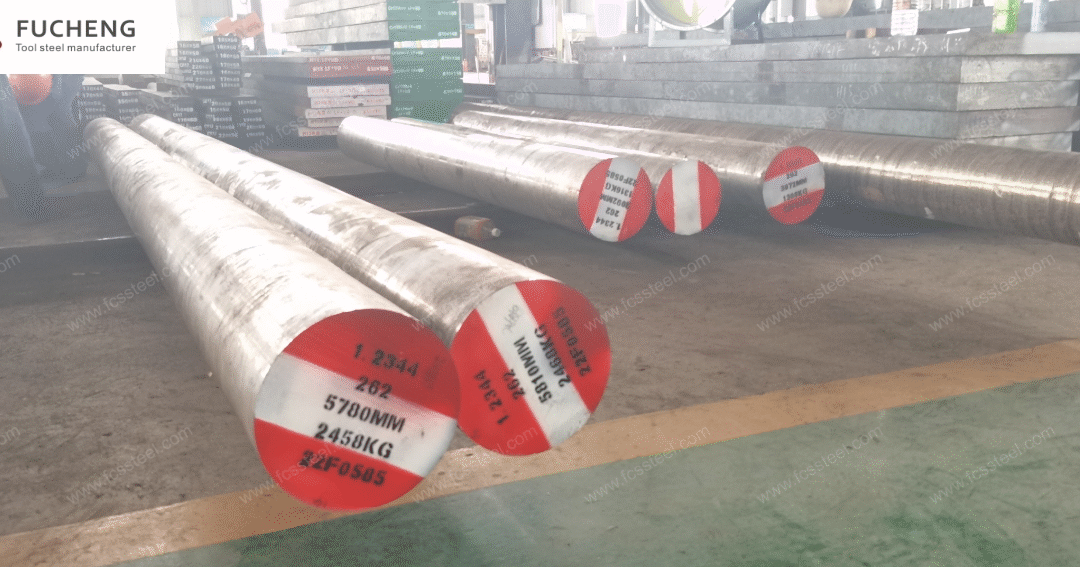

In today’s increasingly competitive manufacturing landscape, buyers across industries such as die-casting, injection molding, and forging face continuous pressure to secure tool steels that can deliver superior performance while keeping overall procurement costs...

by allen | Sep 11, 2025 | hot work tool steel

The modern industrial world is built on the strength of materials. From automotive engines and aerospace components to energy infrastructure and consumer products, every manufacturing sector depends on steels that can endure punishing conditions. Among these...

by allen | Sep 10, 2025 | hot work tool steel

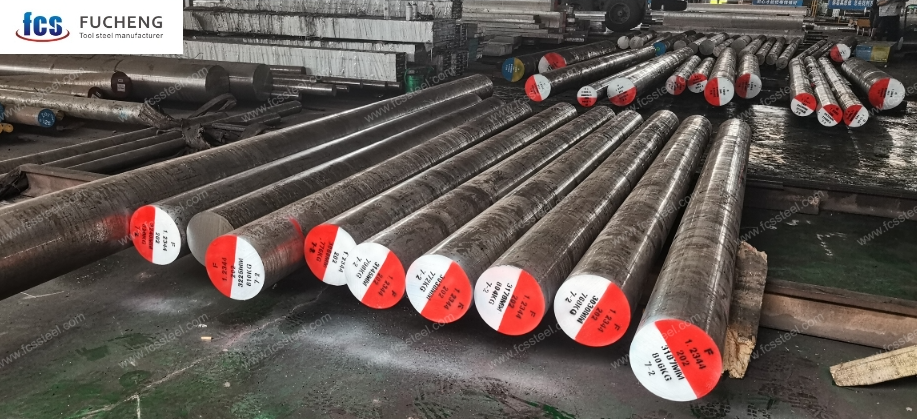

The tool steel industry serves as the backbone of advanced manufacturing sectors, from automotive and aerospace to electronics and energy. Among the numerous grades, 1.2344 tool steel—often cross-referenced with H13 hot-work tool steel—remains a global workhorse...

by allen | Sep 9, 2025 | hot work tool steel

I know choosing between 1.2344 and H13 tool steels can be tricky. Both promise excellent performance, so what makes them different? From my experience, you may need a steel that can handle intense heat without cracking. This is where small differences in their...