by allen | Nov 12, 2025 | cold work tool steel

Over the last decade, Turkey’s industrial sector has become a vital link in the global manufacturing chain. Its toolmaking, automotive, and die-casting industries have expanded significantly, supported by strong local steel production and increasing international...

by allen | Nov 7, 2025 | cold work tool steel

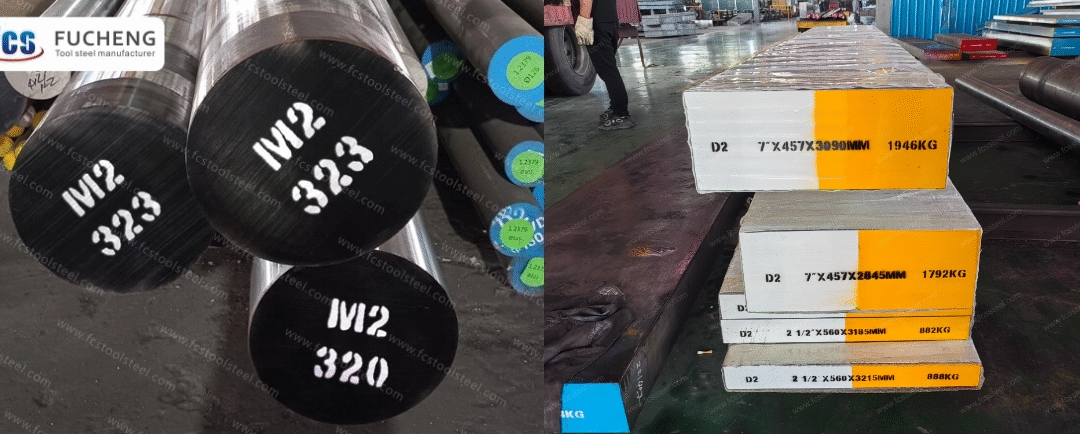

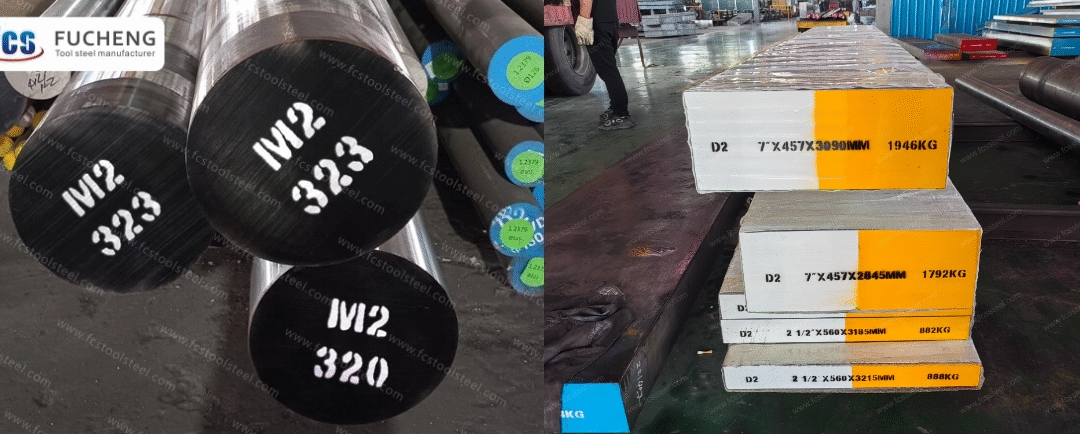

You’re picking tool steel for your next production run. The spec sheet says “D2 grade.” Three quotes just arrived on your desk with very different prices and lead times. One supplier offers German precision at a high cost. Another provides U.S....

by allen | Nov 6, 2025 | cold work tool steel

Think A2 tool steel production means huge carbon emissions? I’ve seen that belief change fast. Makers now show you can create top-grade tool steel. At the same time, they cut environmental harm by over 90%. I recommend looking at new tech like hydrogen...

by allen | Oct 28, 2025 | cold work tool steel, Stainless Steel

Have you seen your knife blade get dull during prep work? You might think you chose the wrong steel. D2 steel and VG10 steel are very different. D2 steel resists wear and handles abrasion well. VG10 fights corrosion and works great for precision cuts. Sushi chefs love...

by allen | Oct 27, 2025 | cold work tool steel, Stainless Steel

Ever wondered why some knife brands thrive while others break even? I believe the secret lies in one critical decision: choosing the right steel. For manufacturers, picking between D2 steel, VG10, 440C steel, and M2 steel isn’t just about sharpness or...

by allen | Oct 24, 2025 | cold work tool steel

In the world of tooling and cutting-machinery, selecting the right steel grade for the job is critical. Two highly prominent grades often compared are AISI D2 tool steel and AISI M2 high-speed steel (HSS). While both can reach similar hardness levels, their alloying,...