Picking steel for your tooling isn’t just about checking a grade on a list. It’s about precision engineering that saves you headaches down the line.

1.2316 steel is famous for being the “corrosion killer” in the plastics industry. But here is the truth: standard, off-the-shelf 1.2316 only gets you halfway there. To really unlock its potential—and stop your molds from pitting after a few PVC runs—you need to customize it.

This guide isn’t a textbook definition. It is a practical handbook on how to spec, buy, and treat 1.2316 steel for real-world manufacturing. You will learn the exact technical tweaks that turn “good enough” into “high performance,” ensuring your supplier delivers material that actually works for your specific cycle times.

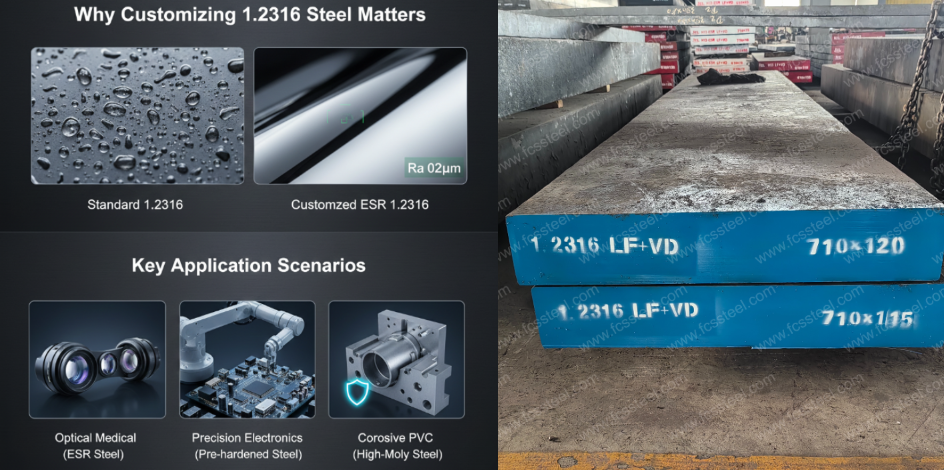

Why Customizing 1.2316 Steel matters

Standard 1.2316 steel offers basic functionality, but tailoring it transforms it into a precision solution for your specific molding challenges:

- Targeted Corrosion Defense: Processing PVC releases corrosive hydrochloric acid. Customizing the Molybdenum content builds a specific shield against this attack, preventing the rapid degradation seen in standard steels.

- Superior Surface Finish: For molds requiring high-gloss optics, standard purity isn’t enough. Custom refinement ensures a clean, pit-free structure essential for achieving flawless mirror finishes

- Dimensional Stability: Specifying the exact pre-hardened state eliminates the risk of warping during heat treatment, ensuring tight tolerances are maintained from the start.

- Optimized Cost-Efficiency: Precision tailoring prevents both under-performance and over-engineering. This balance extends mold life and protects your budget from the 40% faster wear rates typical of non-optimized grades.

When to Customize

Determining when to go beyond standard stock requires looking at your specific production stresses. Here is a breakdown of common scenarios where customization involves critical technical decisions:

|

Application Scenario |

Why Customization is Required |

|---|---|

|

PVC & Corrosive Plastic Molding |

Standard stainless grades often degrade too quickly against hydrochloric acid. You need to verify a higher Molybdenum content (1.0-1.3%) to specifically block pitting corrosion. |

|

High-Gloss & Optical Medical Parts |

Standard purity levels can leave microscopic inclusions. Custom ESR refinement is non-negotiable here to ensure a flawless, pit-free surface for Ra 0.02µm mirror finishes. |

|

Precision Electronics (Complex Geometries) |

Risk of warping is high. Customizing to a Pre-hardened (280-325 HB) state allows you to machine to final tolerance without the distortion risks of post-heat treatment. |

|

Long-Run Production Cycles |

Generic “off-the-shelf” hardness may wear out 40% faster. Specifying precise hardness and microstructure helps balance machinability with the durability needed for high-volume runs. |

Hardness &Heat Treatment Customization

1.2316 steel comes in two main hardness states. These states form the foundation for your mold project. Each state fits different manufacturing needs.

Annealed State: Maximum Machinability

The annealed state delivers ≤235 HB maximum hardness in standard deliveries. Some suppliers offer ranges between 230-255 HB. This soft condition makes machining easy.

Your annealing process runs at 760-800°C for 4-5 hours. Cool the steel slowly at 10-20°C per hour down to 650°C. Then air cool to room temperature. This gives you uniform structure throughout the material.

The result? You get ≤235 HB hardness with consistent grain structure. Complex cavity designs machine faster. Tool wear drops. You save money on cutting tools and machining time.

Use annealed 1.2316 for intricate shapes before heat treatment. The soft state handles deep ribs, thin walls, and detailed features. No cracking. No excessive tool load.

Pre-Hardened State: Ready-to-Machine Stability

Pre-hardened 1.2316 comes at 280-325 HB. That equals 29-33 HRC or about 30 HRC uniform across all dimensions. This state removes heat treatment distortion risks.

You machine without post-hardening. Dimensional stability stays within <0.01mm tolerance. No warping. No size changes. No extra operations to fix distortion.

Suppliers use controlled quench-and-temper processing before delivery. They quench at 1020-1040°C. Then oil quench at 500-550°C. The as-quenched hardness hits 48-52 HRC. Tempering at about 650°C brings hardness down to the target 280-325 HB range.

Quality control checks hardness across all sections. No hard spots. No soft zones. Testing confirms consistent polish speed and mirror surface. No orange peel defects.

Heat Treatment Customization Process

Need specific hardness levels beyond standard delivery states? Follow this 1.2316 steel heat treatment sequence:

Step 1: Stress Relieving

Soak at 600-650°C. Use furnace cooling. This removes stresses from machining or rough shaping.

Step 2: Hardening (Quenching)

Heat your steel to 1020-1040°C. This temperature sits above the Ac3 point of 910°C. Complete change happens here. The Ac1 point is 800°C—stay well above this.

Oil quench at 500-550°C. Your as-quenched hardness reaches 48-52 HRC maximum.

Step 3: Tempering for Target Hardness

For 280-325 HB (29-33 HRC): Temper at about 650°C.

For different hardness levels: Adjust tempering temperature. Post-temper hardness ranges from 32-49 HRC based on temperature.

The martensite start temperature (Ms) sits at about 200°C. This guides your quenching to avoid cracking.

Hardness Selection Guide for Your Application

|

Hardness Level |

Material State |

Best Application Match |

|---|---|---|

|

≤235 HB |

Annealed |

Complex shapes needing lots of machining before final heat treatment |

|

280-325 HB (29-33 HRC) |

Pre-hardened |

Humid areas, wet molding, electronics molds needing mirror finish with zero distortion |

|

>48 HRC |

Hardened |

High wear resistance uses, but risks warping during heat treatment |

Pre-hardened 280-325 HB balances three key factors. Dimensional stability. Excellent polish. Superior rust resistance. You get mirror finishes that hold up in humid conditions. No distortion risk from hardening.

Important note: Avoid nitriding 1.2316 steel. The high chromium blocks nitrogen spread. You’ll get a brittle white layer that fails in service.

Forging controls matter too. Keep forming temperatures below Ac1 (<800°C). Maintain deformation ratios of ≥5:1 for uniform structure across your billet.

Dimension Specifications and Custom Size Options

1.2316 steel suppliers keep many sizes in stock. You can find everything from small tooling parts to large injection mold plates.

Table 1: Standard Round Bar Inventory

|

Product Type |

Diameter Range (∅) |

Surface Finish |

Application Note |

|

Rolled Round Bars |

Ø12-300mm |

Peeled or Turned |

Standard mold bases & inserts |

|

Forged Round Bars |

Ø20-650mm |

Black or Machined |

High-stress molds requiring UT integrity |

Tech Tip: Common stock sizes for immediate dispatch include Ø40, 50, 60, 70, 75, 80, and 85mm

Table 2: Plate and Flat Bar Specifications

| Manufacturing Method | Thickness (T) | Width (W) | Delivery Condition |

|---|---|---|---|

| Standard Stock Plates | 12–300 mm | Up to 1000 mm | Focus on 31–80 mm for fast shipping |

| Ingot Cast Plates | 15–185 mm | Custom | Pre-hardened 280–325 HB |

| Forged Flats | 30–400 mm | 500–1200 mm | Quenched & Tempered (+QT) |

| Special Thin Plates | Down to 8 mm | Custom | Specialized precision processing |

Table 3: Custom Machining & Surface Quality Standards

|

Specification |

Details / Value |

Standards & Compliance |

|

Hardness Range |

300 -340HB (Pre-hardened) |

Uniform through-hardness |

|

Black Surface |

Straightness ≤ 2.5mm/m |

As-rolled or Forged |

|

Machined Surface |

Straightness ≤1.5mm/m |

Turned or Milled |

|

Modular Sizes |

120-300mm × 300-1000mm |

Optimized for mold base designs |

|

Quality Norms |

ISO 4957 / EN 4957 |

Full batch traceability |

Corrosion Resistance and Material Purity Control

1.2316 steel gets its corrosion performance from its chemical makeup. Chromium and molybdenum work together to build a strong defense against harsh plastics.

1. Chromium-Molybdenum Defense System

Chromium at 15.5-17.5% builds a passive Cr₂O₃ layer on the steel surface. This oxide film stops acidic attack from PVC and SMC resins during molding. The layer heals itself after scratches. Your mold cavity stays protected.

Molybdenum at 0.8-1.3% prevents pitting corrosion. Mo strengthens the passive film right where chloride ions try to break through. Crevice corrosion drops. Your mold handles harsh chemicals that would ruin standard tool steels.

Measured Corrosion Resistance Performance

Real tests prove 1.2316 offers top protection. HCl tests at 1% concentration and 20°C show the difference:

|

Steel Grade |

Weight Loss 1 Hour |

Weight Loss 3 Hours |

Corrosion Rate |

|---|---|---|---|

|

1.2316 |

~5mg |

~15mg |

3x slower than 1.2083 |

|

~15mg |

~35mg |

Standard baseline |

1.2316 loses just 5mg in the first hour. Compare that to 15mg for 1.2083. After three hours, the gap grows—15mg versus 35mg. That’s 3 times better resistance in acidic conditions you see in PVC work.

2. Material Purity Through Advanced Metallurgy

Clean steel inside matters just as much as chemistry. Super clean technology uses multiple refining steps:

-

EAF (Electric Arc Furnace) melts the base material

-

LF (Ladle Furnace) refines composition

-

VD (Vacuum Degassing) removes hydrogen and nitrogen

-

ESR (Electroslag Remelting) removes non-metallic particles

This process keeps non-metallic particles at ≤1.0-1.5 per ASTM E45 standards. Fewer particles mean easier polishing. No pits. No surface flaws that trap harmful chemicals.

The even internal structure stops pearlite from forming. You get the same hardness throughout the material. 280-325 HB stays constant from surface to core. Polish quality hits Ra 0.02µm mirror finish with no scratches from particles.

3. Carbon and Residual Element Control

Carbon at 0.33-0.45% balances hardness and toughness. Manganese at 1.00-1.30% boosts hardenability. Silicon at 0.30-0.50% removes oxygen during steel making.

Key purity levels meet strict limits:

– Phosphorus (P): ≤0.030% maximum

– Sulfur (S): ≤0.030% maximum

Low phosphorus stops grain boundaries from becoming brittle. Low sulfur cuts down on MnS particles that ruin polishing. These tight controls give you the clean steel needed for mirror-finish molds that face harsh chemicals.

1.2316 gives you longer mold life than 1.2083 in PVC work. Clean chemistry plus advanced refining make the difference. The steel fights off chemical attack and particle-related problems. Your production runs longer. Maintenance costs drop.

Practical Machinability & Polishing Guide

Let’s be honest: 1.2316 steel isn’t the easiest material to cut. With a machinability rating of roughly 4 out of 10, its high chromium content creates drag on your tools. But here is the trade-off: what you lose in cutting speed, you gain in optical-grade polishability.

Here are the practical Do’s and Don’ts to keep your production running smoothly:

✅ The Do’s: Machining & Polishing Strategies

-

Stick to Pre-Hardened (280-325 HB): This is the “sweet spot.” You get consistent cutting forces from surface to core, with no pearlite bands to dull your inserts unpredictably.

-

Use Stainless-Specific Carbide: Don’t rely on general-purpose HSS tools. You need inserts coated specifically for high-alloy stainless grades to manage the heat and tough chip formation.

-

Follow the Polishing Ladder: Thanks to strict impurity control (Sulfur ≤0.030%), you can achieve a true Ra 0.02µm mirror finish. Start with fine grinding to remove machining marks, move to abrasive stones, and finish with diamond compounds.

❌ The Don’ts: Critical Processing Warnings

-

Don’t Weld Unless Absolutely Necessary: 1.2316 has poor weldability. The risk of cracking is high due to its chemical makeup. Design your mold with inserts to avoid needing weld repairs later.

-

Don’t Attempt Nitriding: The high chromium content blocks nitrogen diffusion, creating a brittle “white layer” that will likely flake off during operation.

-

Don’t Skip Stress Relieving: If you are doing heavy roughing on annealed stock, stress relieve at 600-650°C before final heat treatment to stop your mold from twisting out of tolerance.

Quality Assurance and Testing Standards

Steel suppliers test 1.2316 at multiple checkpoints. Tests run from raw material to final delivery. Each test protects your mold quality. You get documented proof the material meets specs.

Essential 1.2316 Documentation Checklist

Don’t accept your steel delivery blindly. Verify these specific documents are in your package to ensure you get exactly what you paid for:

- Mill Test Certificate (MTC): Specifically EN 10204 Type 3.1 (showing chemical composition).

- Ultrasonic Test (UT) Report: Confirmation of internal integrity (e.g., SEP 1921 Class C/c).

- Hardness Selection Report: Mapping hardness values across the block surface and core.

- Heat Treatment Data Sheet: Time and temperature logs (crucial for pre-hardened stock).

- Dimensional Inspection Report: Verification of tolerance, flatness, and straightness.

- Grain Size Analysis: Proof of microstructure refinement (essential for mirror polishing).

- Certificate of Origin: Ensures full batch traceability to the manufacturer.

Pro Tip: Request digital copies before shipment leaves the warehouse to avoid return logistics for non-compliant material.

Supplier Selection and Procurement Guidelines

The right 1.2316 steel supplier impacts your mold quality and production timeline. Three core factors separate professional suppliers from average vendors: proven track record with industry leaders, complete material traceability systems, and strict metallurgical process controls.

How to Buy 1.2316 Steel: A Step-by-Step Guide

Follow this exact sequence to ensure you get the right material without unnecessary back-and-forth:

- Define Material State: Clearly specify Annealed (≤235 HB) for heavy machining or Pre-hardened (280-325 HB) to avoid heat treatment distortion.

- Set Dimensions & Surface: List exact thickness/diameter. State if you need “Black Surface” (rough, strictly for stock) or “Machined” (milled/turned, ready for cavity work).

- Mandate Chemical Limits: On your Purchase Order (PO), explicitly require Sulfur (S) and Phosphorus (P) ≤0.030%. This is non-negotiable for mirror polishing.

- Specify Refining Tech: For high-gloss molds, demand ESR (Electroslag Remelting) grade steel to ensure no surface pits exist.

- Request Proof Before Shipping: Require digital copies of the Mill Test Certificate (EN 10204 3.1) and Ultrasonic Test Report (SEP 1921 Class C/c) for approval prior to dispatch.

- Confirm Tolerance: For pre-machined blocks, specify flatness and thickness tolerances (e.g., +0.5mm/-0mm) to minimize your internal prep time.

Conclusion

1.2316 steel customization separates basic tooling from high-performance manufacturing. Whether battling corrosive PVC or chasing optical-grade finishes, off-the-shelf specs often overlook the details that matter most.

Success relies on precision—defining exact hardness, verifying chemical purity, and controlling heat treatment. Don’t just order steel; demand a solution tailored to your specific cycle times and stress factors.

The effort you put into specifying requirements today pays off in longer mold life and reduced maintenance tomorrow. Define your standards, verify the quality, and build better molds.