SKD61 tool steel and SKD6 tool steel are two of the most common JIS hot-work tool steels used in die-casting, forging, and extrusion shops. Both are designed to handle high heat and constant thermal cycling, and each aligns with an international grade—SKD61 corresponds to H13 tool steel, while SKD6 matches H11 tool steel.

Although they look similar on paper, the two steels behave quite differently once they go into production. SKD61 holds its hardness and strength at higher working temperatures, which is why it dominates long-running die-casting and aluminum extrusion work. SKD6, on the other hand, delivers stronger toughness and is more forgiving under impact or sudden temperature swings, often making it the better choice in shock-prone applications.

This guide presents a clear, engineering-level comparison of both grades, along with real cases and insights from shop-floor experience.

Chemical Composition & Mechanical Properties

Comparison Table: Composition & Mechanical Properties

| Property | SKD61 (H13) | SKD6 (H11) |

|---|---|---|

| Main Alloy Elements | 4.8–5.5% Cr, 1.0–1.5% Mo, 0.8–1.2% V | 4.5–5.5% Cr, 1.0–1.5% Mo, 0.3–0.6% V |

| Hardness (HRC) | 50–55 | 45–50 |

| Tensile Strength (MPa) | 1450–1650 | 1200–1590 |

| Impact/Toughness (J) | High | Very High (20–30 J typical) |

| Thermal-Fatigue Resistance | Excellent | Very Good |

| Max Service Temperature | 540–600 °C | 500–550 °C |

| Thermal Conductivity (W/m·K) | 24–32 | Lower |

| Machinability | 65–70% | Good |

| Typical Uses | Die-casting, hot forging, aluminum extrusion | Punches, shock-loaded dies, shear blades |

| Material Cost (USD/ton) | 900–2,200 | 600–1,500 |

Hardness vs. Toughness

SKD61 reaches 50–55 HRC after proper heat treatment, and its tensile strength can exceed 1600 MPa. This makes it stable in continuous thermal cycles, typically seen in molds running 50,000–150,000 shots. Even when exposed to high thermal gradients, SKD61 retains its shape and dimensional accuracy.

SKD6, by contrast, is slightly softer but absorbs mechanical impact much better. In forging shops, H11/SKD6 dies often outperform H13/SKD61 when subjected to heavy shock loads. The toughness range of 20–30 J is particularly valued in header dies, clamping blocks, and hot punches.

Bottom line:

SKD61 behaves like a high-endurance runner—consistent under prolonged heat.

SKD6 is the sturdy athlete—built to withstand repeated impacts.

Thermal Performance & Mold Lifespan

High-temperature stability is where SKD61 truly separates from SKD6. It maintains hot hardness and structural integrity at temperatures approaching 600 °C, allowing longer service life in aluminum die-casting or extrusion dies. SKD6, however, performs better in applications where the tool is exposed to sudden thermal shock.

Thermal Performance Comparison

| Property | SKD61 | SKD6 |

|---|---|---|

| Max Working Temp | 540–600 °C | 500–550 °C |

| Hot Hardness @ 538 °C | 45–50 HRC | 45–48 HRC |

| Thermal Shock Resistance | Moderate | Excellent |

| Typical Mold Lifespan | 50,000–150,000 cycles | 15,000–50,000 cycles |

| Best For | Steady high-heat continuous cycles | Rapid heating/cooling & impact loads |

Field Example: Automotive Die-Casting

In a Japanese Tier-1 supplier’s facility, SKD61 ejector pins lasted over 120,000 cycles in a 900-ton aluminum cell using water-cooled inserts. When switched to SKD6 due to cost pressure, cracking appeared at around 35,000 cycles, caused by its lower thermal-fatigue resistance.

The conclusion from engineers onsite was clear: SKD6 is not suited for sustained high-temperature zones.

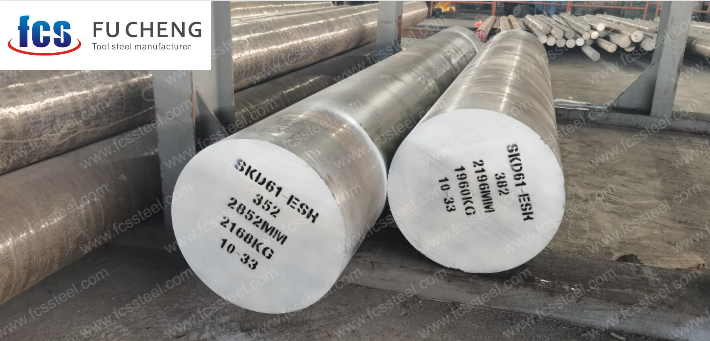

Real Case: FCS Steel SKD61 Performance

As an engineer evaluating SKD61 from multiple suppliers, I’ve consistently found that FCS Steel’s SKD61 ranks among the most stable in terms of hardenability and post-heat-treatment microstructure.

Key Observations from Industrial Use:

– Stock sizes commonly used: Ø70–700 mm round bars, 20–500 mm plates

– Heat treatment used: 1020–1050 °C quench, followed by 2–3 tempering cycles

– Achieved hardness: 56–58 HRC without brittleness

– Real lifespan improvement: 30–50% longer than lower-grade SKD61 alternatives

– Applications: Die-casting molds, extrusion dies, hot forging tools

The stable martensite formation and low impurity control were significant contributors to its consistent high-temperature durability.

Cost & Return on Investment (ROI)

Choosing between SKD61 and SKD6 should never stop at raw material cost. The total cost of ownership (TCO) changes dramatically depending on tool life, heat-treat performance, and maintenance downtime.

Cost & ROI Comparison

| Factor | SKD61 | SKD6 |

|---|---|---|

| Material Cost | 900–2,200 USD/ton | 600–1,500 USD/ton |

| Tool Life | Up to 150,000 shots | 15,000–50,000 shots |

| Maintenance | Less frequent | More frequent under heat |

| ROI | Excellent for high-volume tooling | Good for shock-loaded tooling |

Industry Note

In one aluminum injection plant I worked with, switching from SKD6 to SKD61 for gating inserts increased tooling cost by 18% but reduced unplanned downtime by 42%, resulting in monthly savings exceeding USD 9,000.

Application Guide

SKD61:

- Die-casting molds (aluminum, zinc, magnesium)

- Extrusion dies for non-ferrous alloys

- High-temp plastic injection molds

- Hot forging dies

- Shear blades and hot punches

SKD6:

- Hot punches, gripper and header dies

- Hot shear blades

- Forging dies under shock or rapid thermal cycles

- Budget-friendly die-casting molds

Tip: Match steel choice to temperature, impact load, and production volume to get the best results.

Heat Treatment Tips

- SKD61: Multi-step tempering stabilizes martensite and improves fatigue resistance

- SKD6: Temper at 550–650 °C for a balance of hardness and toughness

- Avoid: Rapid quenching or under-tempering, which can cause microcracks

Proper heat treatment ensures consistent mold performance and longer life.

Expert Recommendations

- Choose SKD61 for high-temp, high-volume precision molds

- Choose SKD6 for impact-heavy, budget-conscious molds

- Always check supplier certificates and heat-treatment logs

- Consider total cost of ownership (TCO), not just material cost

Conclusion

In real factory conditions, SKD61 consistently outperforms SKD6 in high-temperature and long-run tooling because of its superior thermal-fatigue resistance, vanadium-enhanced wear behavior, and stronger hot hardness. SKD6, however, remains highly valuable in shock-loaded dies due to its toughness and cost efficiency. Rather than selecting solely based on price or grade reputation, the smarter approach is to analyze what your tool faces most: heat, impact, or cycle count. Once that requirement is clear, the choice between SKD61 and SKD6 becomes straightforward—and your mold life, downtime, and production stability will reflect the correct decision.