W300 Tool Steel

W300 Tool Steel corresponds to grades such as 1.2343,H11,SKD6,X38CrMoV5-1,4Cr5MoSiV,4X5MΦC, etc. in multiple global standards.

Supply status and size specifications of W300

- W300 Delivery condition: Annealed state (HB ≤229)

- W300 Supply forms: round steel, flat steel, plates, forgings, custom cutting

- W300 Optional sizes: Diameter Φ10 ~ Φ65/Φ 70 ~ Φ400/500/600/700 mm,thickness 8-45/50-500mm,width 50-1000mm/50-1500mm, Forged disc ≤ 1200mm,

etc

W300 Tool Steel Forming Process Options

W300 Hot Rolled,W300 Hot Forged

W300 Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

What is W300 tool steel?

Böhler W300 Tool Steel (1.2343/ X37CrMOV5-1 /H11/SKD6), this steel combines processability and durability, making it an ideal choice for mold manufacturing and high-temperature tooling materials.

What are the specifications of W300 tool steel?

What are the Equivalent Grades of W300 Tool Steel?

What is the Chemical Composition of W300 Tool Steel?

What are the Customized Options of W300 Tool Steel ?

- Custom Chemical Composition: Capable of producing standard grades such as GB, DIN, ASTM, JIS, etc. Chemical composition can be custom-produced individually.

- Custom Specifications: Round steel (diameter) and plates (thickness, width) can be custom-produced.

- Professional packaging for long-term storage or extreme transportation conditions: Including black paint spraying on all sides, plastic film wrapping, anti-rust oil spraying, and delivery in wooden cases.

- Custom production according to samples or technical agreements.

- W302 Tool Steel Electroslag Remelting (W300 ESR): Premium option with higher purity and isotropic properties for critical applications.

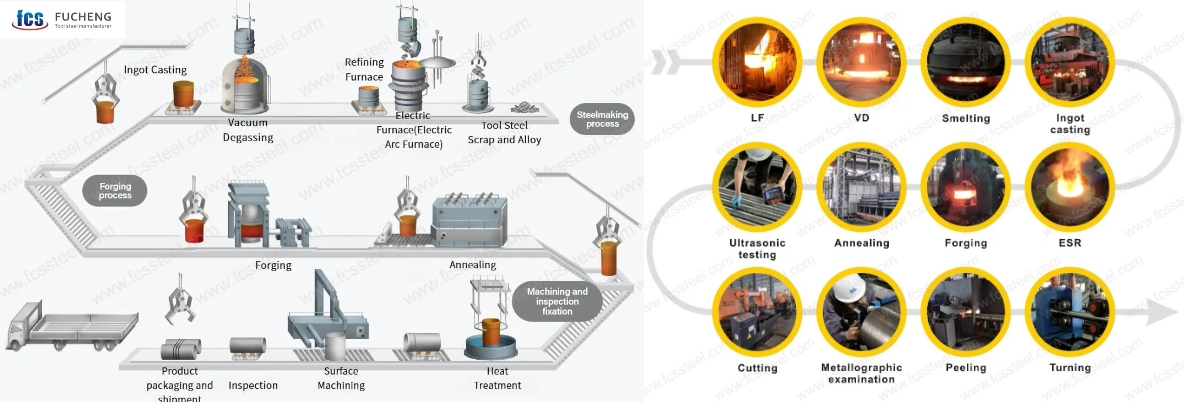

What is the Smelting process of W300 Tool Steel ?

W300 Tool Steel Physical properties

- Excellent processability.

- Good thermal conductivity.

- Excellent polishing performance.

- High microscopic cleanliness.

W300 Tool Steel Typical application fields

-

- Hot extrusion dies, hot forging dies.

- Low-pressure/high-pressure casting molds (including hot-runner systems).

- Plastic injection molds, high-gloss molds (emphasizing polishing).

- General high-temperature components for mechanical engineering, screws and cylinders, shearing tools, tool fixtures, etc.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |