SUS420J2 Tool Steel

SUS420J2 is a martensitic stainless steel optimised specifically for plastic moulding. Its stainless steel nature (chromium-based corrosion resistance + martensitic organisation) meets the basic material properties, while the mirror finish machinability, pre-hardened supply and corrosion-resistant reinforced design for moulding needs make it a dedicated tool steel for corrosive plastic moulding scenarios. When selecting a material, the type of corrosive media, surface finish requirements and cost constraints need to be prioritised in order to maximise its value.

In summary, SUS420J2 is a special steel that combines the nature of a stainless steel with the application characteristics of a plastic mould steel, and its dual properties are reflected in the material composition, properties and application scenarios.

SUS420J2 Tool Steel Product Introduction

SUS420J2 tool steel is a high-grade martensitic stainless steel according to the Japanese Industrial Standard (JIS G4303). It is characterised by its high carbon content and excellent hardness, wear resistance and corrosion resistance in moderate environments. This alloy belongs to the 13Cr series of stainless steels, known for their ability to be heat-treated to obtain high hardness while maintaining basic corrosion resistance.It is suitable for applications requiring dimensional stability under moderate thermal loads. Although its corrosion resistance is adequate for atmospheric and weakly acidic conditions, it is generally recommended for use in non-critical corrosive environments or in conjunction with surface treatments such as nitriding or PVD coating. The alloy's composition and heat treatment reactions are strictly controlled to JIS standards, ensuring consistent performance in mould and structural applications.

SUS420J2 Tool Steel Types and Options

The table below shows the size range, surface condition and tolerance details for SUS420J2 Mould Steel:

SUS420J2 Tool Steel Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- SUS420J2 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

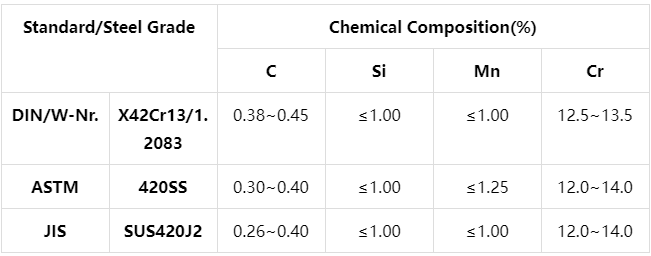

SUS420J2 Tool Steel Chemical Composition

SUS420J2 Tool Steel Heat Treatment Process

1.Annealing

Purpose: to eliminate internal stresses generated during forging or rolling, reduce hardness, improve cutting performance, and prepare for subsequent processing and heat treatment.

Process parameters:

Heating temperature: 800-850 ℃, holding time 2-4 hours, with the furnace cooling to below 500 ℃, and then air-cooled.

2.Quenching

Purpose: to make the tool steel to obtain martensitic organization, improve hardness and wear resistance.

Process parameters:

Heating temperature: 1000-1050 ℃ (commonly used 1020-1040 ℃), holding time according to the size of the workpiece to determine, generally 30-60 minutes.

Cooling: oil cooling or air cooling (for small size or simple shape of the workpiece), large workpieces can be graded quenching (in the 260-300 ℃ salt bath cooling for a period of time and then air-cooled), in order to reduce the quenching stress, to prevent deformation and cracking.

3.Tempering

Purpose: to eliminate quenching stress, adjust the hardness and toughness, stable organization and size.

Process parameters:

low-temperature tempering: 150-250 ℃, insulation 2-3 hours, air-cooled, tempered hardness of 58-62HRC, for molds requiring high hardness and wear resistance.

Medium temperature tempering: 300-500 ℃, insulation 2-3 hours, air-cooled, tempered hardness of 50-58HRC, can improve the toughness, suitable for molds subject to impact load.

High-temperature tempering: 500 ℃ or more, insulation 2-3 hours, air-cooled, tempered hardness 45-50HRC, mainly for the need for higher toughness of the occasion.

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

Tempering must be sufficient to ensure the elimination of internal stresses to avoid mold failure due to stress release during use. For large molds or workpieces with complex shapes, multiple tempering can be used.

SUS420J2 Tool Steel Quality Inspection

1.Surface Condition Inspection

FCS factory has a very strict quality inspection team, we will carefully check the surface condition of each piece of tool steel to ensure that the steel surface is free from cracks, folds, knots, oxidized skin, pitting, scratches and other defects.

2.Chemical Composition Testing

To verify whether the content of alloying elements meets the standard requirements and to safeguard the basis of the mechanical properties of the material. We will let the staff use full-spectrum direct reading spectrometer to analyze multiple elements at the same time. Sampling needs to remove the surface oxidation layer, using a block specimen to stimulate the test.

3.Dimension and Tolerance Inspection

FCS factory will use professional measuring tools to inspect the dimensions and tolerances of the steel to ensure compliance with the customer's contract requirements. Corresponding gauges will be selected according to the dimensional accuracy requirements, including tape measure, high-precision vernier calipers (0.02mm), micrometers (0.001mm), and special inspection gauges. Inspection items cover: diameter, thickness, width, length, hole diameter, chamfering dimensions, etc., to ensure that the tolerances and dimensions meet the contract requirements.

4.Hardness test

Our FCS factory will use professional hardness tester to test the hardness of steel to ensure that it meets the customer's contract requirements.

5.Ultrasonic Testing

Ultrasonic Testing Standard (UT Test Standard) is: Sep 1921-84 Class3 D/d,E/e.

FCS factory uses ultrasonic testing equipment to detect macro defects inside the material (such as cracks, shrinkage holes, inclusions, white spots, etc.), and every piece of round steel and plate will be examined by a second flaw detection test before shipment to ensure that the quality is qualified before shipment.

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

FCS factory will use the comparative method to determine the austenite grain size by comparing the microstructure of the specimen with the standard rating chart, to ensure that it meets the customer's requirements.

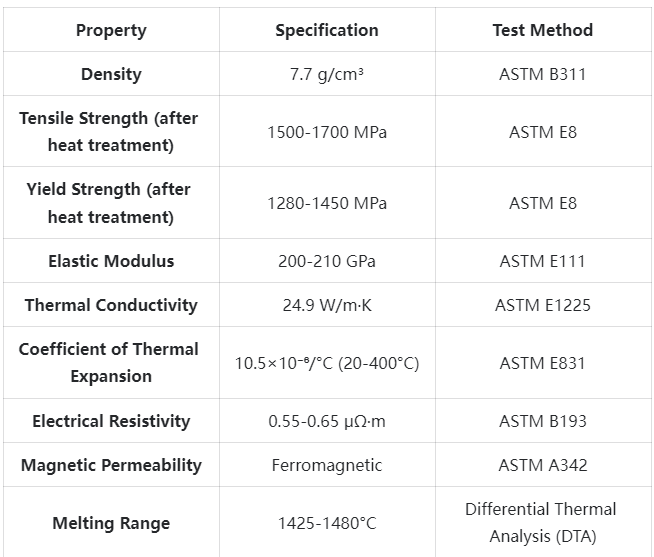

SUS420J2 Tool Steel Technical Specifications

SUS420J2 Tool Steel Product Applications

- Aerospace: jigs, fixtures and cutting tools for aluminium and composite machining

- Automotive: stamping dies, injection moulds for electronic components, calibration gauges

- Medical equipment: surgical instruments, dental tools, sterilizable parts

- Food processing: slicing inserts, forming dies, mixing components, packaging tools

- Pharmaceutical: tablet punching dies, components for clean-room equipment

- Electronics: moulds for sensitive electronic components, precision assembly Fixtures

- Marine: corrosion-resistant components, bearings, fasteners exposed to seawater

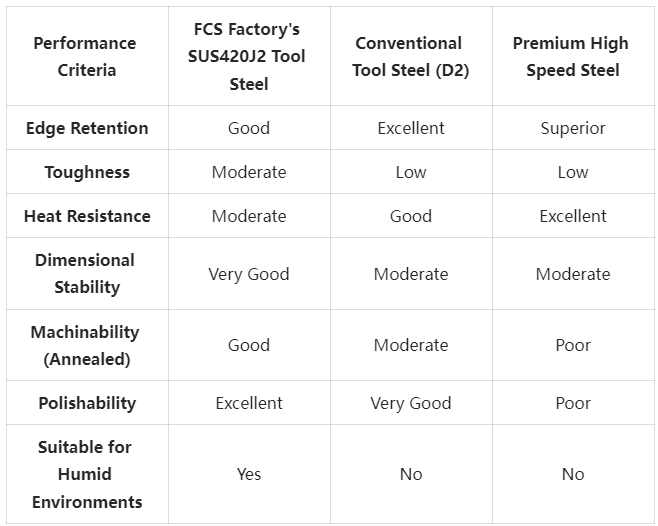

SUS420J2 Tool Steel Competitive Advantage Comparison

SUS420J2 Tool Steel Customer Success Stories

Skip the middleman link, source factory purchasing, reduce purchasing cost and improve market competitiveness.

SUS420J2 Tool Steel Pricing Structure Information

Serving the world, whole cabinet sales, factory wholesale price.

SUS420J2 Tool Steel Frequently Asked Questions

Q:What is the main difference between SUS420J2 and standard 420 stainless steel?

A:SUS420J2 has a more tightly controlled carbon content (0.26-0.35%) compared to 0.15-0.40% for standard 420 stainless steel. This narrower range ensures a more consistent heat treat response and predictable hardness. In addition, our SUS420J2 undergoes more rigorous processing to ensure purer steel and improved microstructural uniformity.Q: Is SUS420J2 suitable for food contact applications?

A:Yes, after proper surface treatment and passivation, SUS420J2 meets the requirements for food contact applications. Its excellent corrosion resistance makes it ideally suited for food processing equipment, especially in environments that require regular cleaning and sanitising.Q:How does the corrosion resistance of SUS420J2 compare to other tool steels?

A:The corrosion resistance of SUS420J2 is significantly better than non-stainless tool steels such as D2 or A2. In standard salt spray testing (ASTM B117), SUS420J2 typically remains virtually corrosion free after 96 hours, while conventional tool steels show surface corrosion within 10-12 hours.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |

.png)

.png)

.png)

.png)