SKD1 Tool Steel

In modern manufacturing environments, where tool failure due to wear and distortion leads to high production downtime costs and quality issues, SKD1 tool steel is optimised for high carbon and chromium content, demonstrating excellent wear resistance and dimensional stability in high stress applications. Companies using SKD1 for critical mould components report up to 40% longer tool life, significantly shorter maintenance intervals and improved end-product consistency. As a professional-grade cold work tool steel, SKD1 offers the perfect balance of hardness, toughness and machinability to meet the needs of precision moulds and high-performance industrial tools.

SKD1 Tool Steel Product Introduction

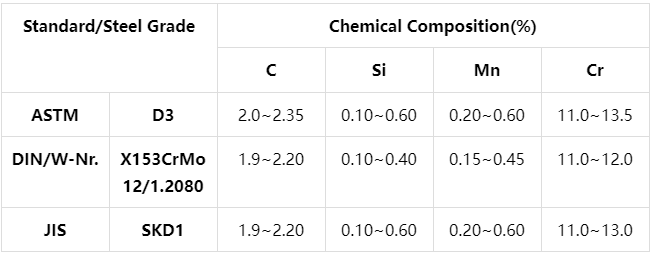

SKD1 is a high-carbon, high-chromium cold work mould steel under the Japanese JIS G4404 standard, belonging to the Rheinzite steel type. Its corresponding American ASTM grade is D3, the corresponding German DIN/W-Nr grade is X210Cr12/1.2080, the corresponding Chinese GB grade is Cr12. its chemical composition strictly control phosphorus, sulfur impurities, and contains a small amount of silicon (and manganese, through the vacuum refining and spheroidal annealing process to optimise the organisational homogeneity, the hardness of the factory is 255 HBS, with a high degree of purity and processability. High purity and processability.

The core advantage of this steel is its ultra-high wear resistance and hardness stability. The heat treatment process requires strict temperature control (quenching temperature 950°C-1000°C) to avoid overheating-induced hardness degradation, and stress-relief tempering to reduce distortion and ensure long-term dimensional stability and corrosion resistance.

SKD1 Tool Steel Types and Options

The table below shows the size range, surface condition and tolerance details for SKD1 Mould Steel:

SKD1 Tool Steel Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- SKD1 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

SKD1 Tool Steel Chemical Composition

SKD1 Tool Steel Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

SKD1 Tool Steel Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

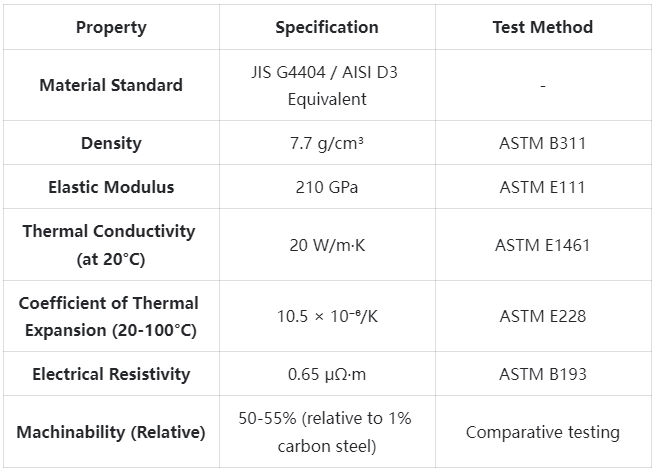

SKD1 Tool Steel Technical Specifications

SKD1 Tool Steel Product Applications

Main application scenarios

Dropping and Stamping Dies

SKD1 excels in high-volume dropping and stamping in automotive and appliance manufacturing. Even after millions of cycles, it maintains precise edge profiles and reduces tool maintenance intervals by 40%. An automotive parts supplier uses SKD1 for chassis component stamping dies, and the frequency of die refurbishment has changed from monthly to quarterly, which directly improves productivity and part quality.

Cold forming tools

SKD1 combines wear resistance and compressive strength in cold extrusion, drawing and forming applications. Heat-treated dimensional stability ensures precision in complex moulding applications. An industrial fastener manufacturer used SKD1 cold heading dies to increase tool life by 35% and improve part consistency.

Industrial Shear Blades

SKD1's excellent edge retention makes it suitable for industrial shearing in steel processing. The balance of hardness and toughness prevents chipping and cracking and maintains a sharp edge. SKD1 cuts cleaner cuts and reduces blade replacement costs by up to 25% for service centres cutting high-strength steel.

Precision Gauges and Measuring Instruments

SKD1's superior dimensional stability makes it a perfect fit for precision measuring and calibrating tools. Stress relieved and stabilised, parts maintain micron-level tolerances even with temperature fluctuations. Metrology equipment manufacturers use it as a reference gauge for long-term calibration accuracy.

Wire Rolling Dies

SKD1 excels in wire rolling applications where surface wear is critical. Precise contours are maintained under high cyclic loads, ensuring consistent thread quality over long production cycles. Fastener manufacturers using SKD1 wire rolling dies have seen a 50% increase in die life in high strength material applications.

Industry-specific applications

- Automotive Manufacturing: High Strength Steel Stamping Dies, Dressing Dies, Forming Tools

- Aerospace: Precision Forming Tools, Specialty Cutting Tools, Measuring Equipment

- Electronics: Connector Manufacturing Progressive Dies, Precision Punching Heads

- Fastener Manufacturing: Rolling Dies, Cold Heading Dies, Dressing Tools

- Appliance Manufacturing: Large Sheet Metal Component Stamping/Molding Dies

- Plastic Moulding: Injection Moulded Inserts Exposed to Abrasive Compounds

- Metalworking: Industrial Cutting tools, slitting tools, shearing blades

SKD1 Tool Steel Competitive Advantage Comparison

SKD1 Tool Steel Customer Success Stories

SKD1 Tool Steel Pricing Structure Information

SKD1 Tool Steel Frequently Asked Questions

Q: How does SKD1 compare with D2 and A2 tool steels?

A:SKD1 wear resistance is superior to D2 and A2, hardness is 2-3 HRC higher than typical D2; heat treatment dimensional stability is superior to A2, cutting edge retention is superior to both.SKD1 chromium content is higher than A2 (good corrosion resistance), and the toughness after optimisation of the composition is superior to that of standard D2.Q:Can SKD1 be processed in hardened state?

A:SKD1 is mainly processed in the annealed state (220-250 HB), and can also be processed in the hardened state: EDM is preferred for complex features; grinding, CBN hard turning, and carbide drilling are also feasible (depending on the parameters). Suggestions for key features: leave 0.1-0.2mm machining allowance in the annealed state, and finish grind after hardening.Q:Precautions for storage of SKD1 parts?

A:They should be stored in a low humidity environment and rust inhibitor should be applied to exposed surfaces. VCI (Vapour Phase Inhibition) packaging is recommended for long term storage. Clean machining fluids, dry thoroughly, and lightly coat with protective oil; sealed packaging + desiccant (to prevent condensation from temperature fluctuations) is recommended for critical parts.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |