K107 Tool Steel

K107 tool steel is a high carbon, high chromium cold work tool steel, standardized under the Austrian (ÖNORM) designation system.

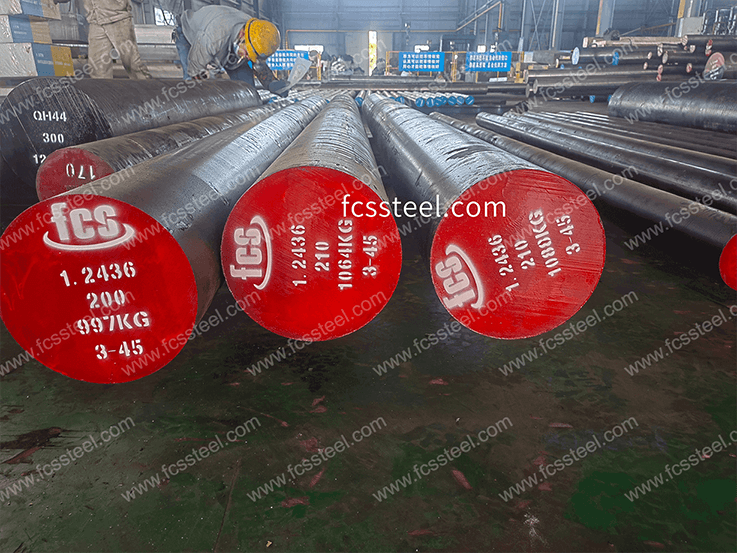

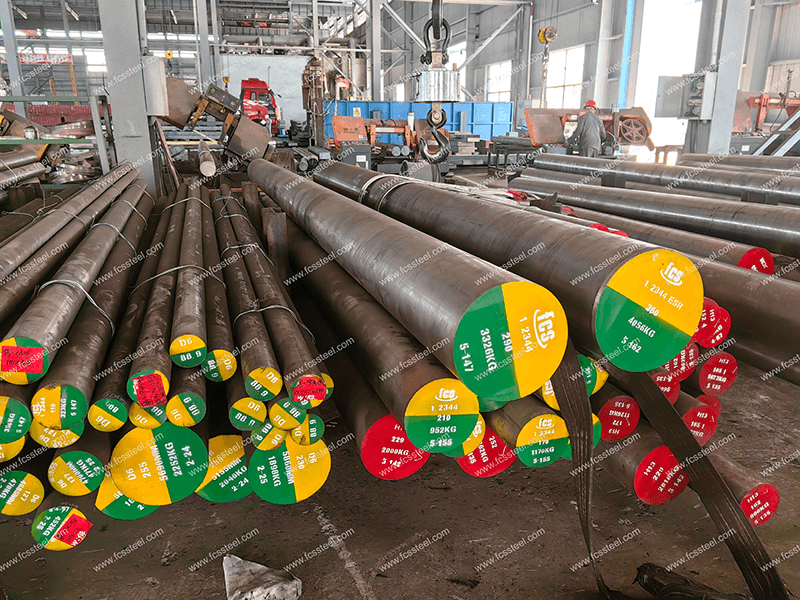

Supply status and size specifications of K107

- K107 Delivery condition: Annealed state (HB ≤ 255)

- K107 Supply forms: round steel, flat steel, plates, forgings, custom cutting

- K107 Optional sizes: Diameter Φ10 ~ Φ65/Φ 70 ~ Φ400/500/600/700 mm,thickness 8-45/50-500mm,width 50-1000mm/50-1500mm, Forged disc ≤ 1200mm,

etc

K107 Tool Steel Forming Process Options

K107 Hot Rolled,K107 Hot Forged

K107 Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

What is K107 tool steel?

K107 is a die steel in accordance with the Austrian Bohler standard and belongs to the category of deep-hardened oil-quenched tool steel. Compared with conventional Cr12 or K100 steel, K107 has a higher carbon content and an excellent hardening depth, making it more suitable for cold working scenarios where wear resistance and pressure bearing capacity are required to be more extreme.

K107 steel not only can achieve a hardness of over 60 HRC through heat treatment, but also maintains high hardness while still having good impact toughness. It is particularly suitable for mold designs that require high wear resistance and the ability to withstand heavy impact loads.

What are the specifications of K107 tool steel?

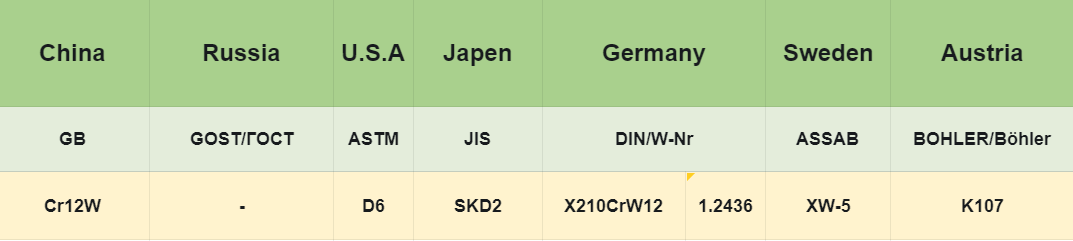

K107 Tool Steel Equivalent Grades

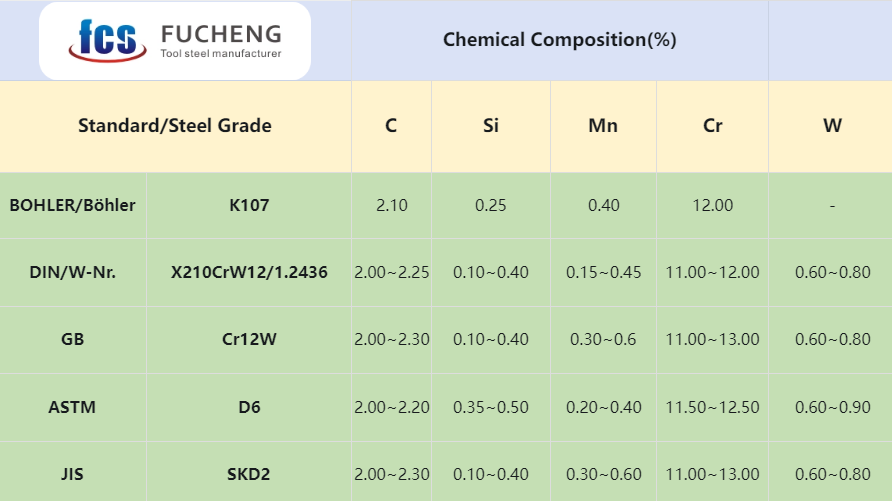

K107 Tool Steel Chemical Composition

K107 Tool Steel Customized Options

- Custom Chemical Composition: Capable of producing standard grades such as GB, DIN, ASTM, JIS, etc. Chemical composition can be custom-produced individually.

- Custom Specifications: Round steel (diameter) and plates (thickness, width) can be custom-produced.

- Professional packaging for long-term storage or extreme transportation conditions: Including black paint spraying on all sides, plastic film wrapping, anti-rust oil spraying, and delivery in wooden cases.

- Custom production according to samples or technical agreements.

- K107 Tool Steel Electroslag Remelting (K107 ESR): Premium option with higher purity and isotropic properties for critical applications.

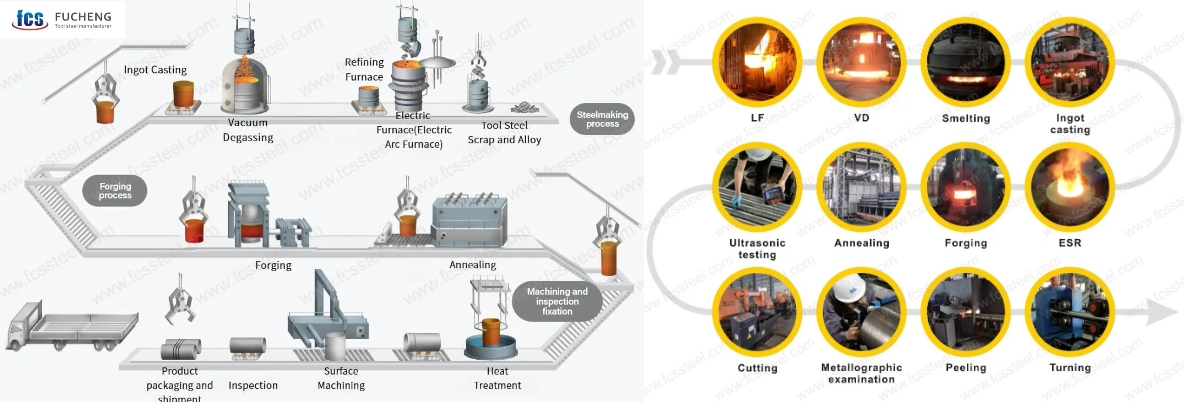

K107 Tool Steel Smelting process

K107 Tool Steel Core Performance Highlights

- 🔨 Excellent compressive strength: suitable for high-load cold working dies

- 🔁 High heat treatment stability: minimal dimensional deformation after quenching

- ✂️ is compatible with high-precision processing technologies: electrical discharge machining, wire cutting, and engraving are all compatible

- ♻️ can be used as a substrate for coated molds: it has good compatibility with PVD/CVD performance

K107 Tool Steel Application Field Recommendation

K107 is a high-grade cold work steel solution designed to withstand extreme wear resistance and moderate impact, suitable for the following working conditions:

- 📦 stamping dies: stamping of automotive steel plates, home appliance shells, and high-strength thin plates

- 🪚 Shearing tools: thick plate edge trimming, high-speed cutting, helical shearing dies

- 🧲 cold roll die: forming profile die, flanging die, guide block

- 🔩 powder pressing dies: ceramic powder, metal powder pressing die cores

- 🧼 engraving punch/etching die: complex pattern die, roller embossing die

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |

-1-300x300.png)