H11 Tool Steel| 1.2343 | X38CrMoV5-1

Industry-leading H11/1.2343/X38CrMoV5-1 tool steel designed for die casting applications, extrusion tooling and forging dies.FCS Factory’s tool steel materials combine outstanding durability, optimal thermal conductivity and high temperature performance up to 500°C.

H11 Tool Steel| 1.2343 | X38CrMoV5-1 Product Introduction

H11 Tool Steel (AISI/ASTM Standard)

H11 tool steel is a chromium-molybdenum-vanadium alloyed hot work tool steel (AISI/ASTM Standard) with a typical composition of C 0.35-0.40%, Cr 4.75-5.50%, Mo 1.25-1.75%, V 0.30-0.50%. Its core properties are excellent thermal stability (it can maintain ≥52 HRC hardness at 500-550°C) and high toughness, as well as good thermal conductivity (30.4 W/(m-K) at 700°C) and resistance to thermal cracking, but the risk of decarburisation needs to be tightly controlled during heat treatment.

1.2343 Tool steel (W-Nr/GIN standard)

1.2343 tool steel is a German W-Nr/DIN standard hot work tool steel (grade W.Nr. 1.2343) with a chemical composition highly consistent with H11 (C 0.36-0.42%, Cr 4.80 -5.50%, Mo 1.10-1.40%, V 0.30-0.50%). Significant advantages are the fine grain organisation and deep hardenability (oil quenching/air cooling hardness up to 50-56 HRC), as well as the low coefficient of thermal expansion (11.8 x 10-⁶ m/(m-K) at 20-100°C), but multiple temperings (≥2) are required to stabilise the residual austenite.

X38CrMoV5-1 Tool steel (DIN/W-Nr standard)

X38CrMoV5-1 tool steel is a chromium-molybdenum-vanadium hot-work steel according to the German DIN standard (corresponds to H11/1.2343), with a tightly matched compositional range (C 0.35-0.42%, Cr 4.75 -5.50%, Mo 1.10-1.40%, V 0.30-0.50%). The characteristics emphasise high-temperature strength (modulus of elasticity 176 x 10³ N/mm² at 500°C) and thermal fatigue resistance, and its weldability and coefficient of thermal expansion are close to those of ordinary steels, which makes it less susceptible to deformation under complex thermal cycling conditions.

H11 Tool Steel| 1.2343 | X38CrMoV5-1 Types and Options

The table below shows the size range, surface condition and tolerance details for H11/1.2343/X38CrMoV5-1 Tool Steel:

H11 Tool Steel| 1.2343 | X38CrMoV5-1 Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- H11/1.2343/X38CrMoV5-1 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

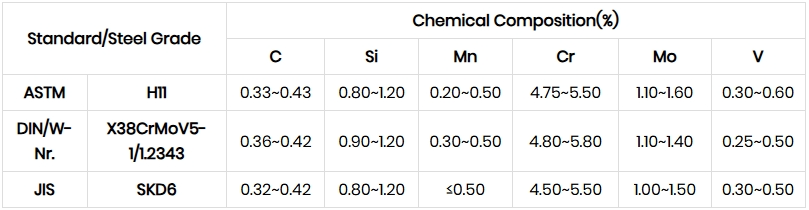

H11 Tool Steel| 1.2343 | X38CrMoV5-1 Chemical Composition

H11 Tool Steel| 1.2343 | X38CrMoV5-1 Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

H11 Tool Steel| 1.2343 | X38CrMoV5-1 Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

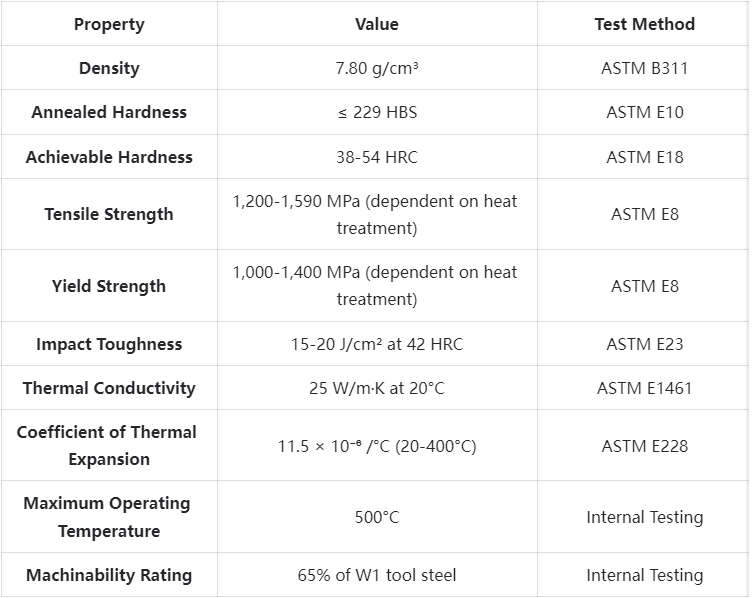

H11 Tool Steel| 1.2343 | X38CrMoV5-1 Technical Specifications

H11 Tool Steel| 1.2343 | X38CrMoV5-1 Product Applications

Key Application Scenarios

Die casting mould applications

Die casting manufacturers rely on our H11/1.2343/X38CrMoV5-1 tool steel to make moulds for processing aluminium, zinc and magnesium alloys. The material's excellent resistance to thermal fatigue extends mould life by up to 30% compared to standard hot work steels. One automotive component manufacturer reports running over 100,000 cycles before needing die maintenance, thanks to the consistent quality of our material and optimised heat treatment process.

Extrusion tooling

Aluminium Extrusion uses our 1.2343 steel for dies, bushings and pressure pads because of its ability to withstand high pressures and temperatures while maintaining dimensional stability. The material's thermal conductivity allows for efficient cooling, resulting in more consistent extruded product dimensions and improved surface quality. Proper heat treating services ensure the best combination of wear resistance and toughness for these demanding applications.

Forging dies and tools

Hot forging operations benefit from the excellent resistance to thermal cracking and plastic deformation of our X38CrMoV5-1 tool steel. The material maintains its mechanical properties at elevated temperatures, providing consistent part geometries even after thousands of forging cycles. Combined with our custom machining and heat treating services, customers report mould life 25-40% longer than conventional materials.

Engineering polymer injection moulds

For injection moulding of glass-filled and other abrasive plastic compounds, our pre-hardened H11 tool steel offers an excellent balance of wear resistance and polishability. The thermal properties of the material ensure efficient cooling and short cycle times. Custom-machined cooling channels and optimised heat treatments provide enhanced performance for high-volume production environments.

Industry-specific Applications

- Automotive: die casting dies for engine blocks, transmission housings, structural components; hot stamping tools for forming high-strength steels

- Aerospace: forging dies for turbine blades, structural components; extrusion dies for specialised aluminium extrusion profiles

- Consumer electronics: precision die casting tools for housings of thin-walled and complex features; tools for insert moulding

- Industrial equipment: heavy-duty moulding tools, hot shear blades, high-temperature punches

- Energy Fields: Tooling for valve components, pressure vessel parts and specialised pipe fittings

H11 Tool Steel| 1.2343 | X38CrMoV5-1 Comparison Summary

H11 Tool Steel| 1.2343 | X38CrMoV5-1 Customer Success Stories

H11 Tool Steel| 1.2343 | X38CrMoV5-1 Pricing Structure Information

H11 Tool Steel| 1.2343 | X38CrMoV5-1 Frequently Asked Questions

Q:What is the difference between H11, 1.2343 and X38CrMoV5-1?

A:These are steel grades from different systems (AISI, DIN and EN respectively) that essentially refer to the same hot work tool steel composition. There are minor specification differences between the standards, but our material meets or exceeds all three.Q:How does electroslag remelting (ESR) improve tool properties?

A:ESR treatment significantly reduces non-metallic inclusions and improves micro-homogeneity, resulting in superior fatigue resistance, better polishability, and more consistent heat treat response. This translates into 30-40% longer tool life in demanding applications.Q:How does H11/1.2343 compare to H13/1.2344 in die casting applications?

A: H11/1.2343 has slightly higher toughness and thermal conductivity than H13/1.2344, making it well suited for large moulds and parts subjected to severe thermal cycling. h13/1.2344 offers slightly better thermal hardness and may be better suited for very high temperature applications.Q:What surface treatments are recommended to extend tool life?

A:Nitriding is very effective in improving surface wear resistance while maintaining core toughness. pvd coatings (especially TiAlN or CrN) are excellent in resisting erosion. For best performance, a controlled nitriding process is often best used in conjunction with a subsequent PVD coating.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |