DC53 tool steel

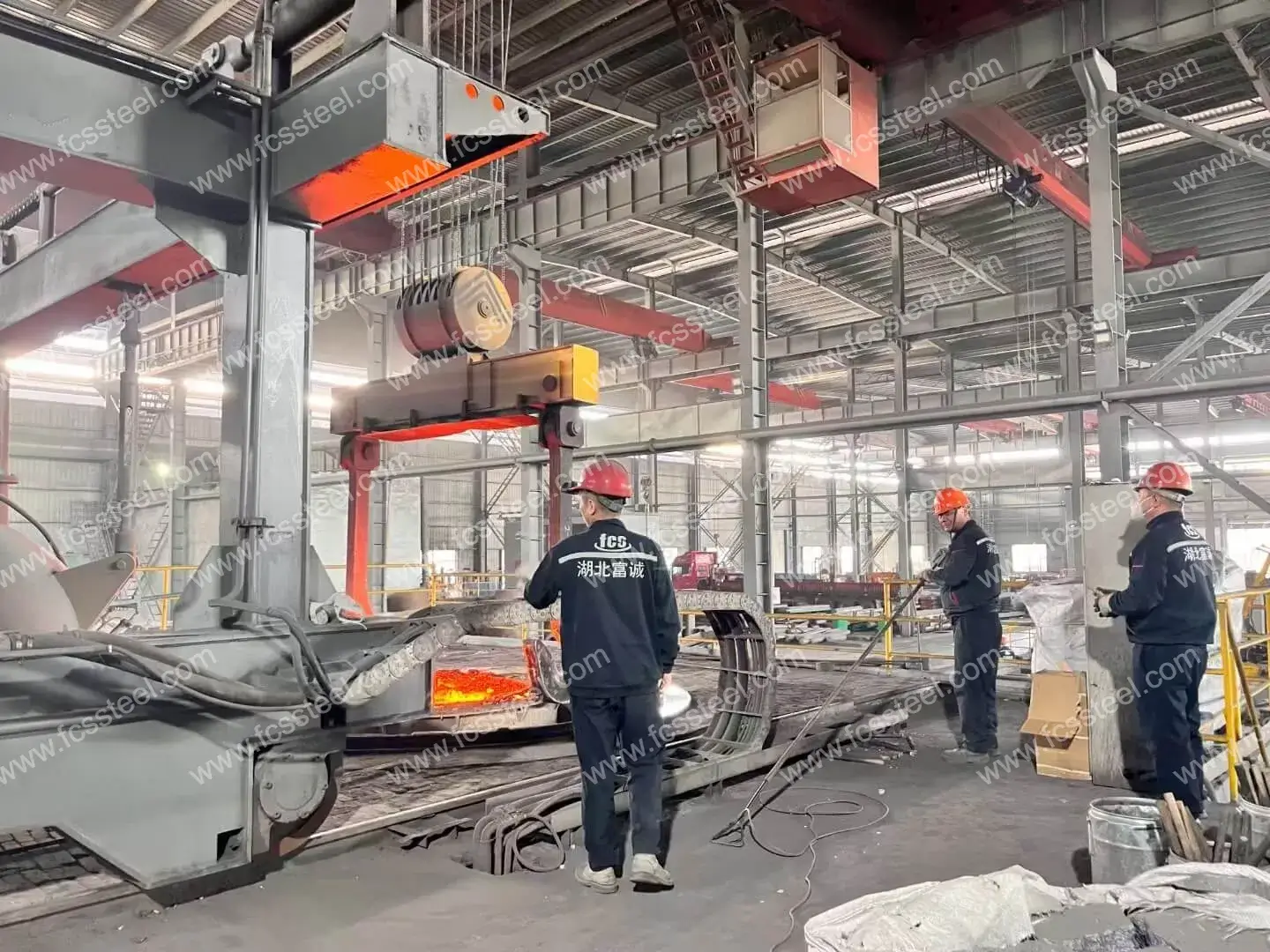

DC53 tool steel represents a new generation of cold work mould steels designed to break through the limitations of traditional D2 and SKD11 grades. This high-end alloy combines the excellent wear resistance of a high carbon tool steel with significantly improved toughness and dimensional stability.

Advanced manufacturing processes ensure a fine and uniform carbide distribution within the material, resulting in excellent edge retention and chipping resistance, even under high impact conditions. This translates directly into longer tool life, longer maintenance intervals and fewer production interruptions.

For manufacturers facing challenging forming, stamping or cutting operations, DC53 offers a balance of performance: high hardness without brittleness, excellent wear resistance with easy machining, and outstanding dimensional stability during heat treatment. The result is a precision tool that accurately maintains critical dimensions, delivers consistent performance, and significantly reduces total production costs.

DC53 Tool Steel Product Introduction

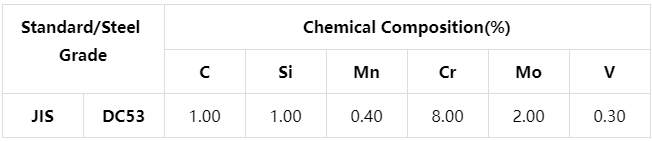

DC53 is a high-hardness and high-toughness cold working die steel that conforms to the Japanese industrial standard (JIS G4404), and is improved on the basis of SKD11 (Cr12MoV). As an upgraded grade of JIS SKD11, the core design objective is to break through the limitation of traditional cold work steel that "high hardness leads to brittleness". Its chemical composition is centered on a balanced ratio, including carbon, chromium, molybdenum, vanadium, and supplemented by elements such as silicon and manganese, while strictly controlling impurities like phosphorus and sulfur. It belongs to the category of high alloy tool steel.

Through specific heat treatment (quenching temperature 1020-1040℃, tempering temperature 520-530℃), DC53 can achieve a high hardness of 62-63 HRC, while its toughness is twice that of SKD11, significantly reducing the risk of tool cracking. The essence of its design is to optimize the distribution of carbides and the decomposition of retained austenite, thereby enhancing machinability, dimensional stability after wire cutting and the convenience of welding repair while maintaining high wear resistance and strength.

As a cold working die steel, DC53 focuses on the core demands of cold working scenarios (such as stamping and cutting) for "wear resistance + crack resistance + dimensional stability". With more balanced mechanical properties, it has become the mainstream material choice for high-end cold working dies and is widely recognized in the global tool steel market as an upgraded alternative to SKD11.

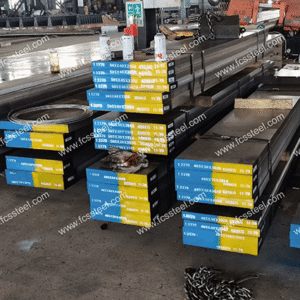

DC53 Tool Steel Types and Options

The table below shows the size range, surface condition and tolerance details for SKD6 Mould Steel:

DC53 Tool Steel Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- DC53 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

DC53 Tool Steel Chemical Composition

DC53 Tool Steel Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

DC53 Tool Steel Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

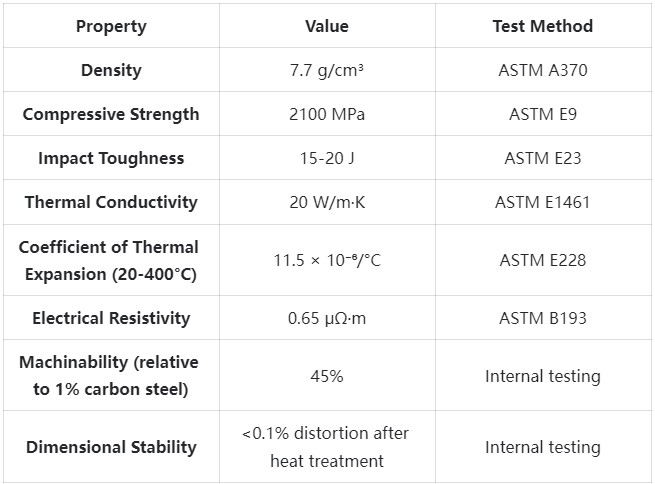

DC53 Tool Steel Technical Specifications

DC53 Tool Steel Product Applications

Cold Forming and Bending Tools

DC53 combines wear resistance and toughness for complex cold forming operations. Feedback from precision medical device manufacturers: DC53 forming tools last up to 40% longer and maintenance is significantly reduced. The material's resistance to high stress deformation/failure translates into more consistent part quality and fewer production interruptions.

Fine Blanking Dies and Punches

DC53's edge strength and wear resistance make it particularly well suited for fine blanking operations. When a leading electronics manufacturer switched to DC53 for electrical sheet metal blanking, tool life increased by 65% and the quality of blanked edges improved dramatically. The material's ability to maintain a sharp edge reduces the need for subsequent finishing operations.

Wear-resistant plastic injection moulds

When forming glass fibre or mineral-filled polymers, conventional mould steels often wear prematurely due to high flow zones. DC53 combines wear resistance with high polishability. Mould makers report that when processing 30% glass-filled engineering plastics, DC53 cavities/cores maintain surface finish and dimensional accuracy approximately 250,000 cycles longer than comparable P20 moulds.

Wire Rolling Moulds

The combination of abrasion resistance and toughness makes DC53 ideal for wire rolling applications. A fastener manufacturer uses DC53 dies to process high-strength threads and has seen a 55% increase in production between die maintenance intervals. The improved rolled wire surface finish also enhanced the fatigue performance of the finished fasteners.

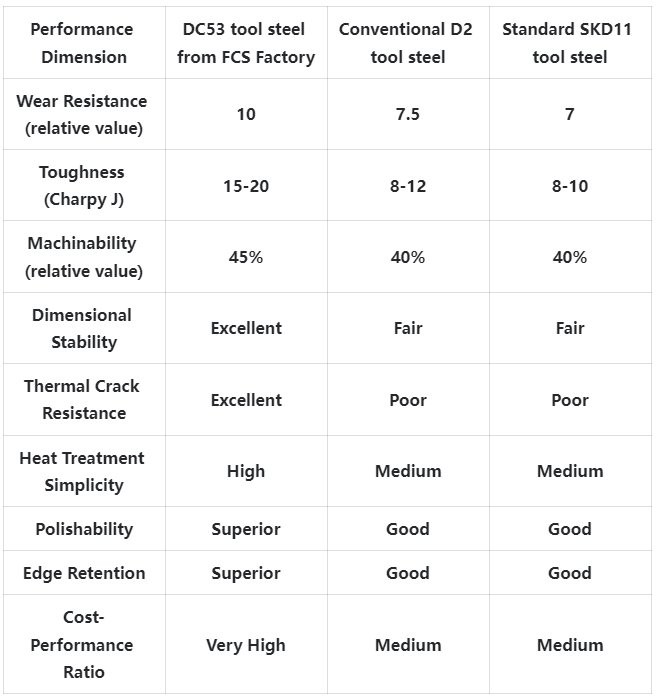

DC53 Tool Steel Competitive Advantage Comparison

DC53 Tool Steel Customer Success Stories

DC53 Tool Steel Pricing Structure Information

DC53 Tool Steel Frequently Asked Questions

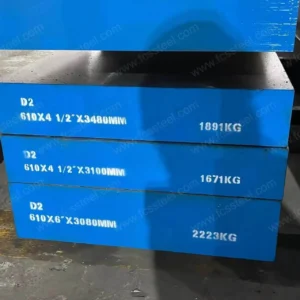

Q: How does DC53 compare to conventional D2/SKD11 tool steels?

A: DC53 has 35% higher wear resistance and 2.5 times the toughness of conventional steels (conventional SKD11). The unique combination prevents progressive wear and sudden chipping. In addition, DC53 has better dimensional stability in heat treatment.Q: Does DC53 require special heat treatment?

A: The heat treatment process for DC53 is similar to that of other tool steels, but requires tighter temperature control (±5°C) to achieve optimum performance. Vacuum heat treatment (to minimise distortion) is recommended for complex shapes.Q: Can an existing mould design be directly replaced with DC53?

A: In most cases, direct replacement is possible without modification. However, in some applications, engineers may recommend design optimisation (e.g., adjusting edge geometry, reducing back angle) to take full advantage of DC53's enhanced performance.Q: How does machinability compare to other tool steels?

A: The machinability of DC53 in the annealed state is comparable or better than that of D2/SKD11. Excellent surface quality and reasonable tool life can be achieved with appropriate cutting parameters. In the hardened condition, despite the high hardness, the grindability is still better than most conventional tool steels.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |