D6 Tool Steel | 1.2436 |X210Crw12

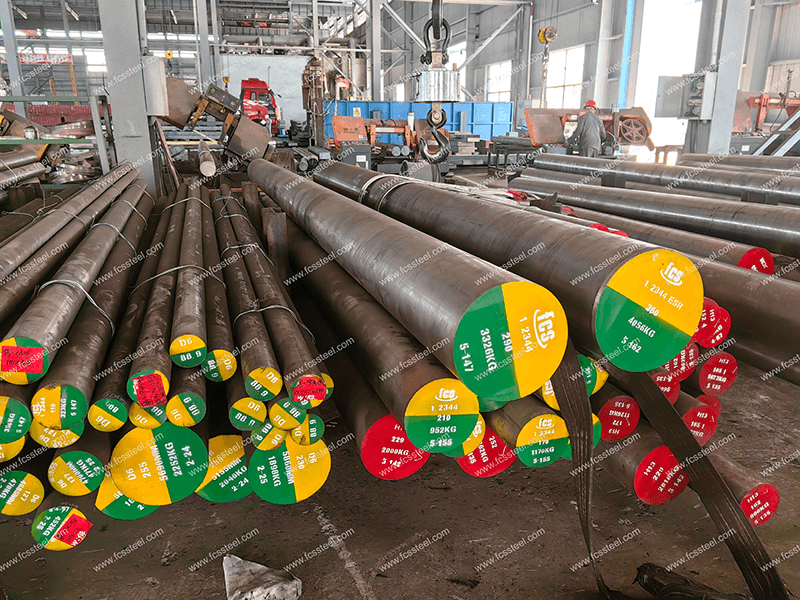

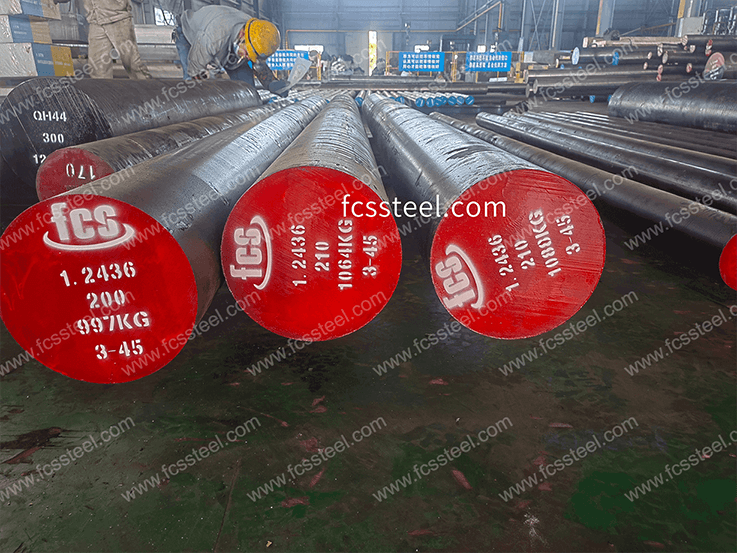

With a large stock of ASTM D6,DIN1.2436/X210CrW12 tool steel, FCS Factory also delivers in custom sizes and offers precision heat treating. Trusted by global manufacturing giants for cold forging dies, aircraft broaches, gauge blocks and critical high wear applications.

D6 Tool Steel | 1.2436 |X210Crw12 Product Introduction

1.2436 Tool Steel (X210CrW12) is a German DIN high carbon, high chromium cold work tool steel (corresponding to grade X210CrW12), which belongs to the Rheinzite type of steel, with the addition of tungsten for enhanced properties.This specialized grade solves the challenge of rapid tool wear in demanding stamping, stock removal, and cutting operations by providing excellent wear resistance and hardness.

D6 is a tool steel grade in the American Standard (ASTM), which belongs to cold work die steel. It corresponds to the Chinese national standard grade Cr12W, the German DIN/W-Nr grade X210CrW12/1.2436, and the Japanese JIS grade SKD2. The smelting and manufacturing methods are: EF+LF+VD+Hot rolled /Hot Forged+Annealed.

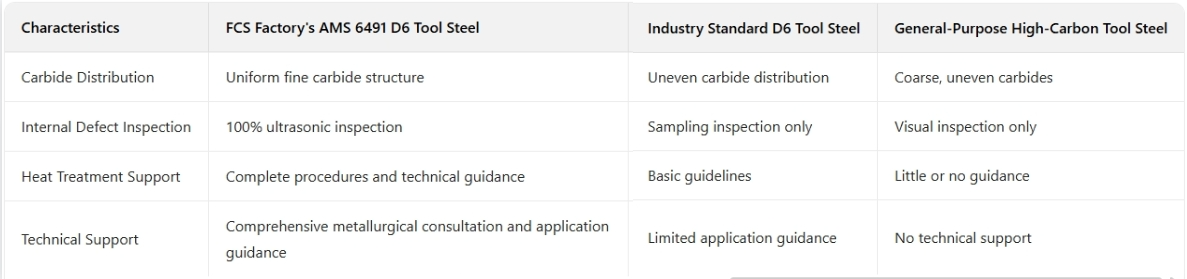

Precision manufacturing and aerospace applications require tool steels with excellent wear resistance and consistent properties under extreme conditions. wear resistance, dimensional stability and consistent performance under extreme conditions. Standard tool steels often fail prematurely in high wear environments or fail to hold critical tolerances during thermal cycling. FCS Factory's 1.2436/X210CrW12/D6 tool steel addresses these challenges with an optimal ratio of high carbon to high chromium, resulting in a dense carbide structure that resists wear and maintains dimensional stability. Each lot is rigorously tested to ensure compliance with aerospace and industry standards.

D6 Tool Steel | 1.2436 |X210Crw12 Types and Options

The table below shows the size range, surface condition and tolerance details for D6/1.2436/X210Crw12 Tool Steel:

D6 Tool Steel | 1.2436 |X210Crw12 Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- D6/1.2436/X210Crw12 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

D6 Tool Steel | 1.2436 |X210Crw12 Chemical Composition

D6 Tool Steel | 1.2436 |X210Crw12 Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

D6 Tool Steel | 1.2436 |X210Crw12 Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

D6 Tool Steel | 1.2436 |X210Crw12 Technical Specifications

D6 Tool Steel | 1.2436 |X210Crw12 Product Applications

1.2436 Tool Steel Key Application Scenarios

High Volume Stamping Dies

1.2436 tool steel excels in high volume stamping operations for automotive parts and metal hardware manufacturing. Its superior wear resistance extends die life by 40% compared to standard D2 tool steel, significantly reducing downtime for tool changes. One automotive supplier reported savings of more than $75,000 per year in tool replacement costs after switching a high-volume door hinge stamping operation to 1.2436 steel.

Precision Drop Tooling

When used in precision drop tooling applications for electronic components and precision parts, 1.2436 tool steel maintains a sharp cutting edge and tight tolerances over long production runs. The combination of high hardness and good dimensional stability ensures consistent part quality even after hundreds of thousands of drop feed operations. One precision connector manufacturer achieved more than 300,000 cycles before the edges wore out, compared to 180,000 cycles with a previously used tooling material.

D6 Tool Steel Key Application Scenarios

Precision Gauge Blocks

The excellent dimensional stability and wear resistance of D6 tool steel makes it ideal for the manufacture of precision gauge blocks and measuring references. Specially heat-treated to 62-64 HRC, our D6 steel maintains a dimensional accuracy of ±0.001mm over many years of use. Calibration laboratories and precision manufacturing companies choose our material especially for its extremely low coefficient of thermal expansion (10.5 x 10^-6/°C) and its resistance to dimensional changes under different humidity conditions. Each block blank is stress relieved and comes with material certification documenting chemical composition and uniformity.

Aircraft Broaching Tools

Aerospace manufacturers rely on our AMS 6491 certified D6 steel for critical broaching tools used in the production of turbine components. The high carbon and chromium content creates a microstructure that maintains a sharp cutting edge under extreme cyclic loads. Properly heat-treated to 60-62 HRC, these tools last up to 40% longer than conventional tool steels when machining nickel-based high-temperature alloys and titanium alloy components. Our aerospace customers place special emphasis on our material traceability documentation and batch consistency to ensure predictable performance in a tightly controlled manufacturing process, avoiding serious downstream consequences of tool failure.

Cold Forging Dies

Cold forging operations subject dies to extremely high stresses and abrasive wear. Our D6 tool steel is heat-treated to 58-60 HRC to provide the optimum balance of wear resistance and toughness for these challenging applications. The high chromium content creates hard carbides that resist distortion while maintaining sufficient matrix toughness to prevent catastrophic failure. Manufacturers of automotive parts, fasteners and precision hardware report producing more than 100,000 pieces per die when using our D6 steel with proper design and lubrication. Each dolly blank comes with a comprehensive heat treatment guide for the specific application.

Industrial Work Rolls

Steel processors use our D6 tool steel in intermediate and finishing applications where surface quality and dimensional consistency are critical. The material's high wear resistance maintains precise roll profiles even after processing thousands of tons of material. After heat treatment according to our specialized procedures, including triple tempering, these work rolls achieve an optimum combination of surface hardness (58-62 HRC) and core toughness. Customers in the rolling mill industry particularly value our ultrasonic testing certification to ensure internal material integrity in high speed rotating applications and to avoid accidental failures that can cause major equipment damage.

Industry-specific applications

Automotive Manufacturing

- Stamping dies for chassis components and body panels

- Progressive dies for small precision parts

- Trimming dies to remove flying edges from castings and forgings

- Drop tools for high strength automotive steels

Aerospace Industry

- Precision cutting tools for titanium and nickel alloys

- Forming dies for sheet metal parts

- Stamping tools for ventilation and weight reduction holes

- Wear plates for material handling equipment

Electronics Manufacturing

- Precision drop tools for electrical contacts

- Precision punches for circuit board assemblies

- Edge trimming tools for connector manufacturing

- Molding dies for radiator and chassis components

Medical device manufacturing

- Cutting dies for surgical instruments

- Molding tools for implanted parts

- Stamping tools for medical device frames

- Precision longitudinal cutters for medical materials

Metal packaging industry

- Molded parts for cans for high-volume production

- Deep drawing dies for metal containers

- Cutting tools for lid manufacturing

- Trimming and forming dies for container closures

D6 Tool Steel | 1.2436 |X210Crw12 Comparison Summary

D6 Tool Steel | 1.2436 |X210Crw12 Customer Success Stories

D6 Tool Steel | 1.2436 |X210Crw12 Pricing Structure Information

D6 Tool Steel | 1.2436 |X210Crw12 Frequently Asked Questions

Q: How does the ESR (Electroslag Remelting) version differ from Standard 1.2436?

A: The ESR version undergoes an additional remelting process that significantly reduces non-metallic inclusions and improves microstructural uniformity. This results in better toughness, improved polishability, enhanced fatigue strength, and more consistent heat treat response.ESR materials are recommended for critical applications where premium performance justifies a 30-40% price premium.

Q: If 1.2436 is not available, what are suitable alternatives?

A: The closest alternatives include 1.2601 (X165CrMoV12), which has similar wear resistance and slightly better toughness, and D2 (1.2379), which has lower wear resistance but better availability. Our technical team can recommend the best alternative for your specific application requirements.

Q: How does D6 tool steel differ from other high carbon tool steels?

A: D6 tool steel has a higher chromium content than most high carbon tool steels, forming a large number of hard chromium carbides in the microstructure. This gives it excellent wear resistance while maintaining good dimensional stability during heat treatment. The high chromium content also provides better corrosion resistance than low alloy tool steels.

Q:What is the difference between Standard D6 and Electroslag Remelting Grade?

A: Standard D6 tool steels have a certain amount of inclusions and carbide segregation, especially in large sizes, which can be centrally loose. ESR D6 tool steels have a reduction in inclusions of more than 50 percent, and the carbides are finely dispersed (e.g., in the form of webs or ribbons), with no significant segregation. For example, the ESR process improves the impact toughness of D6 by a factor of 1.5 and significantly reduces data dispersion.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |

-1-300x300.png)