1.2080 Tool Steel | D3 | X210Cr12

FCS Factory’s premium D3 tool steel (1.2080/X210Cr12) provides excellent wear resistance, dimensional stability, and hardness up to 62 HRC for high-precision cutting tools, shear blades, and molds that require superior wear resistance in demanding industrial environments.

1.2080 Tool Steel | X210Cr12| D3 Product Introduction

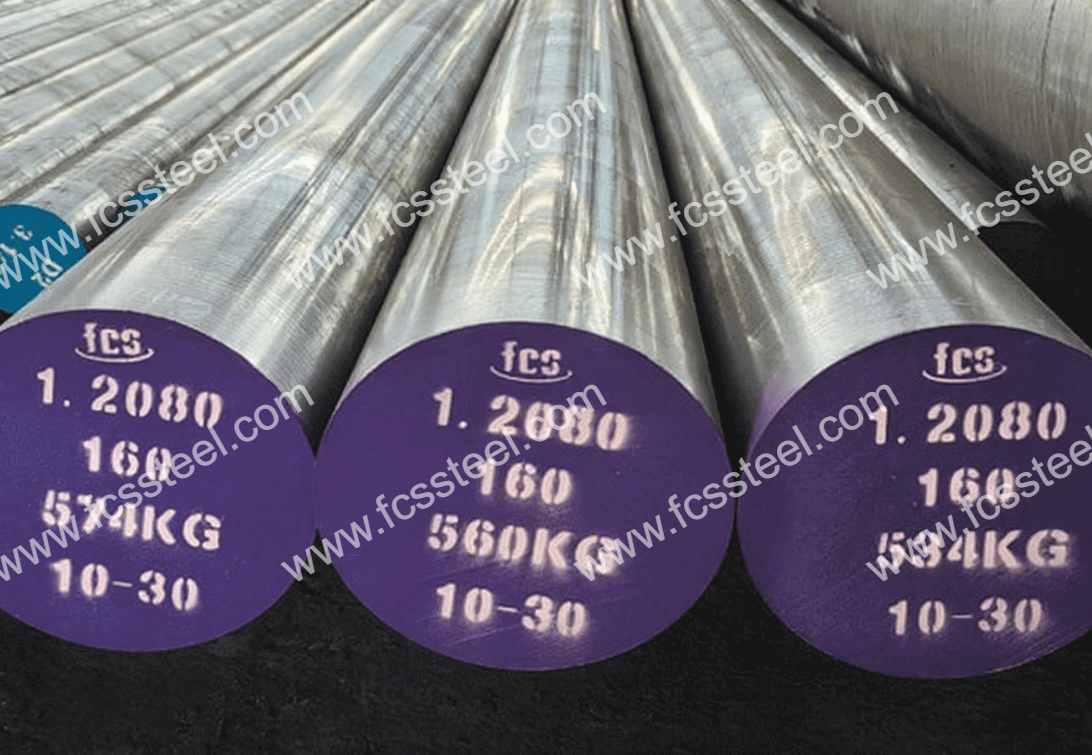

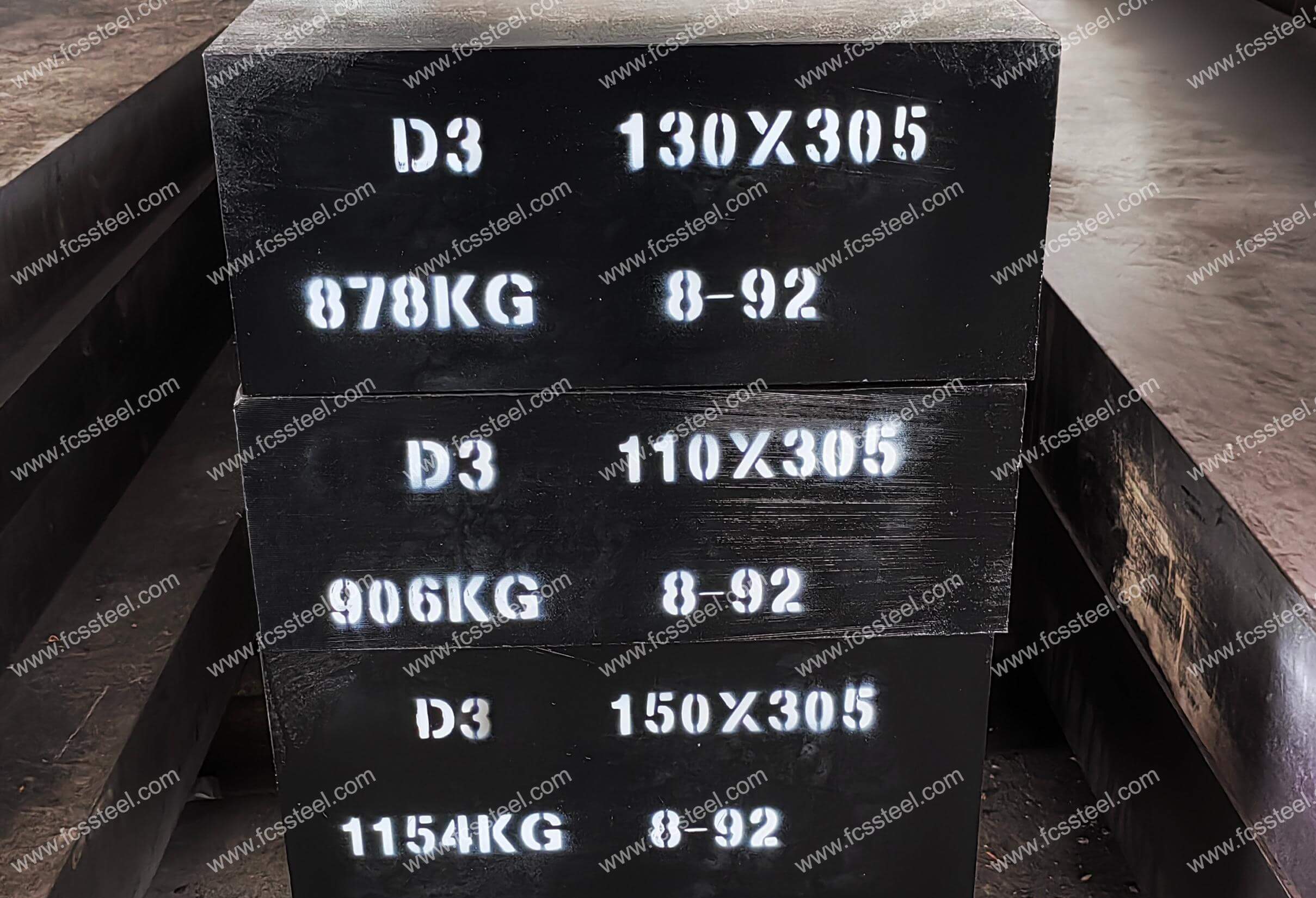

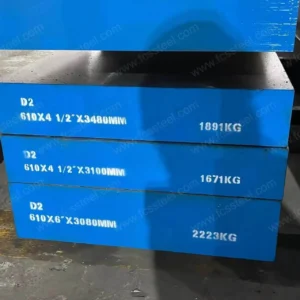

D3 tool steel is the American standard (AISI), and its counterpart X210Cr12, 1.2080 tool steel is the German standard (DIN/W-Nr). All three are high-carbon, high-chromium alexandrite cold work tool steel, with ultra-high wear resistance, high hardness and good dimensional stability as the core advantage, suitable for cold conditions under high stress tool manufacturing, suitable for high-precision, high-load cold tool manufacturing. Its multi-standard naming system (ASTM/DIN/GB) can meet the needs of different regional industrial chains, and is the preferred material for wear-resistant tools in the automotive, cutting tool and electronics industries. As a leading manufacturer and supplier of alloy steel, tool steel, FCS Tool Steel Factory's D3, 1.2080, X210Cr12 tool steel undergoes stringent quality control during the production process. Each batch of material is certified for chemical composition, microstructure and mechanical properties to ensure consistent performance in critical tooling applications. FCS Facyory offers D3, 1.2080, X210Cr12 tool steel tool steel that is precision manufactured to maintain optimum carbide distribution, providing superior edge retention in cutting applications and extended service life in high wear environments compared to standard grades available in the market.

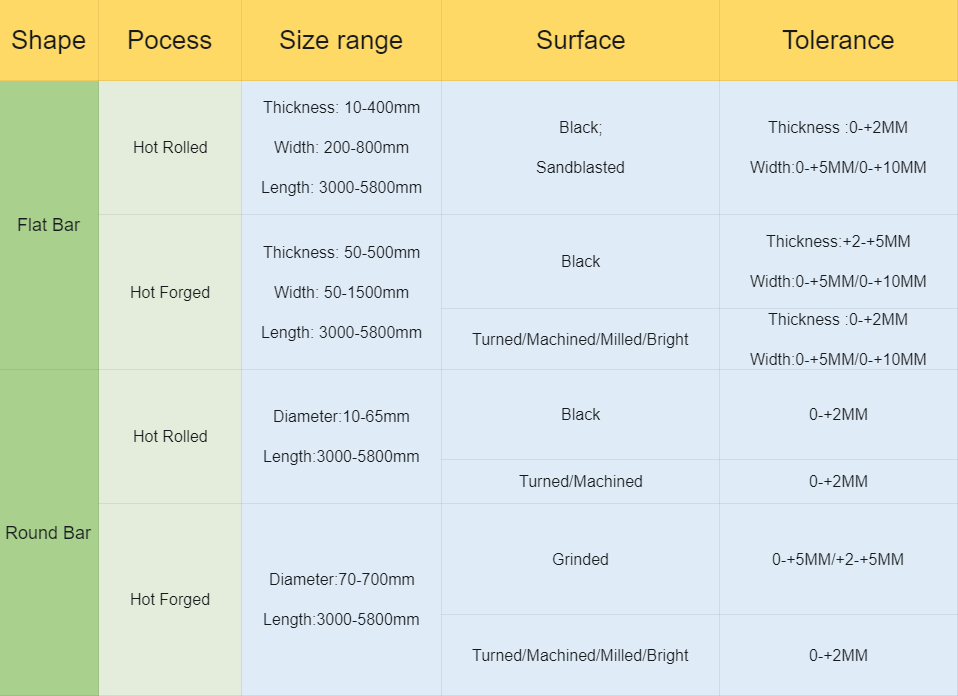

1.2080 Tool Steel | X210Cr12| D3 Types and Options

The table below shows the size range, surface condition and tolerance details for 1.2080/X210Cr12/D3 Tool Steel:

1.2080 Tool Steel | X210Cr12| D3 Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- 1.2080/X210Cr12/D3 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

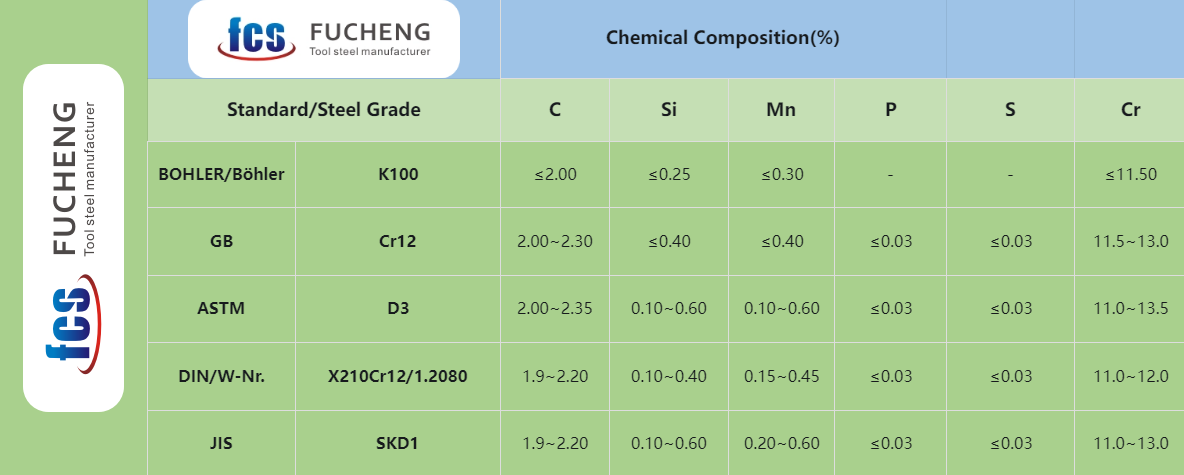

1.2080 Tool Steel | X210Cr12| D3 Chemical Composition

1.2080 Tool Steel | X210Cr12| D3 Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent. When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

1.2080 Tool Steel | X210Cr12| D3 Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

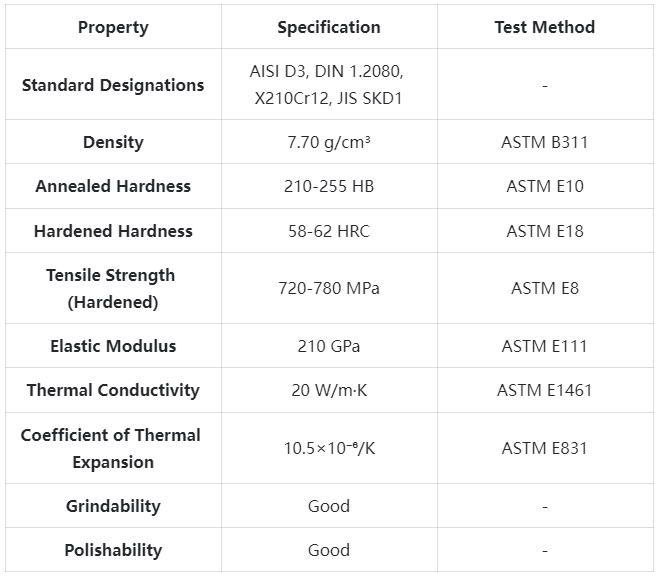

1.2080 Tool Steel | X210Cr12| D3 Technical Specifications

1.2080 Tool Steel | X210Cr12| D3 Product Applications

Key Application Scenarios

High Precision Cutting Dies

D3/1.2080 steel excels in high volume drop stock and stamping operations on materials up to 3mm thick. Its excellent wear resistance extends die life by 30-40% compared to conventional steels, especially when machining abrasive materials such as silicon or stainless steel. Our customers report that over 1 million strokes can be achieved using our premium grade D3 steel with proper heat treatment before regrinding.

Industrial Shear Blades

The high carbon and chromium content of X210Cr12 steel creates the perfect balance of hardness and wear resistance for industrial shear applications. Metal fabricators using our 1.2080 steel for shear blades report 2-3 times longer service intervals compared to standard tool steel. The material's ability to maintain a sharp edge significantly improves cut quality and reduces burr formation.

Injection Molds

For injection molds that process abrasive or glass-filled compounds, our D3 tool steel offers excellent resistance to erosive wear. Excellent dimensional stability during heat treatment ensures the accuracy of critical mold components, while good polishability allows for a high-quality surface finish. Molders report consistent performance and minimal maintenance, even after hundreds of thousands of molding cycles.

Industry-specific applications

- Automotive manufacturing: drop and punch dies for high-volume sheet stamping; precision molding tools for transmission components; high-load bearing guides and wear plates; wire roll dies for fastener production.

- Aerospace industry: tools for machining titanium and superalloys; precision measuring gauges requiring dimensional stability; specialized cutting tools for composites; and wear-resistant fixtures and tool holders.

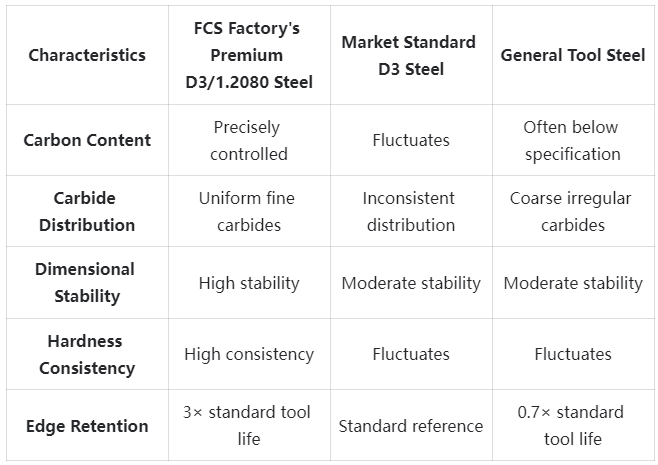

1.2080 Tool Steel | X210Cr12| D3 Comparison Summary

1.2080 Tool Steel | X210Cr12| D3 Customer Success Stories

1.2080 Tool Steel | X210Cr12| D3 Pricing Structure Information

1.2080 Tool Steel | X210Cr12| D3 Frequently Asked Questions

Q: What is the maximum hardness that D3/1.2080/X210Cr12 steel can achieve? A: Our D3 steel can be hardened to 60-62 HRC with proper heat treatment. The maximum actual hardness depends on the cross-section size, and thicker sections are usually 1-2 HRC lower than thinner sections due to hardenability limitations. Q: How does D3 compare to D2 tool steels in cutting applications? A: D3 (1.2080) has a higher carbon and usually higher chromium content than D2 (1.2379), resulting in excellent wear resistance but slightly lower toughness.D3 is the preferred choice for applications where abrasive wear is a primary concern, while D2 provides a better balance of wear resistance and toughness in applications where there is some impact loading.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |