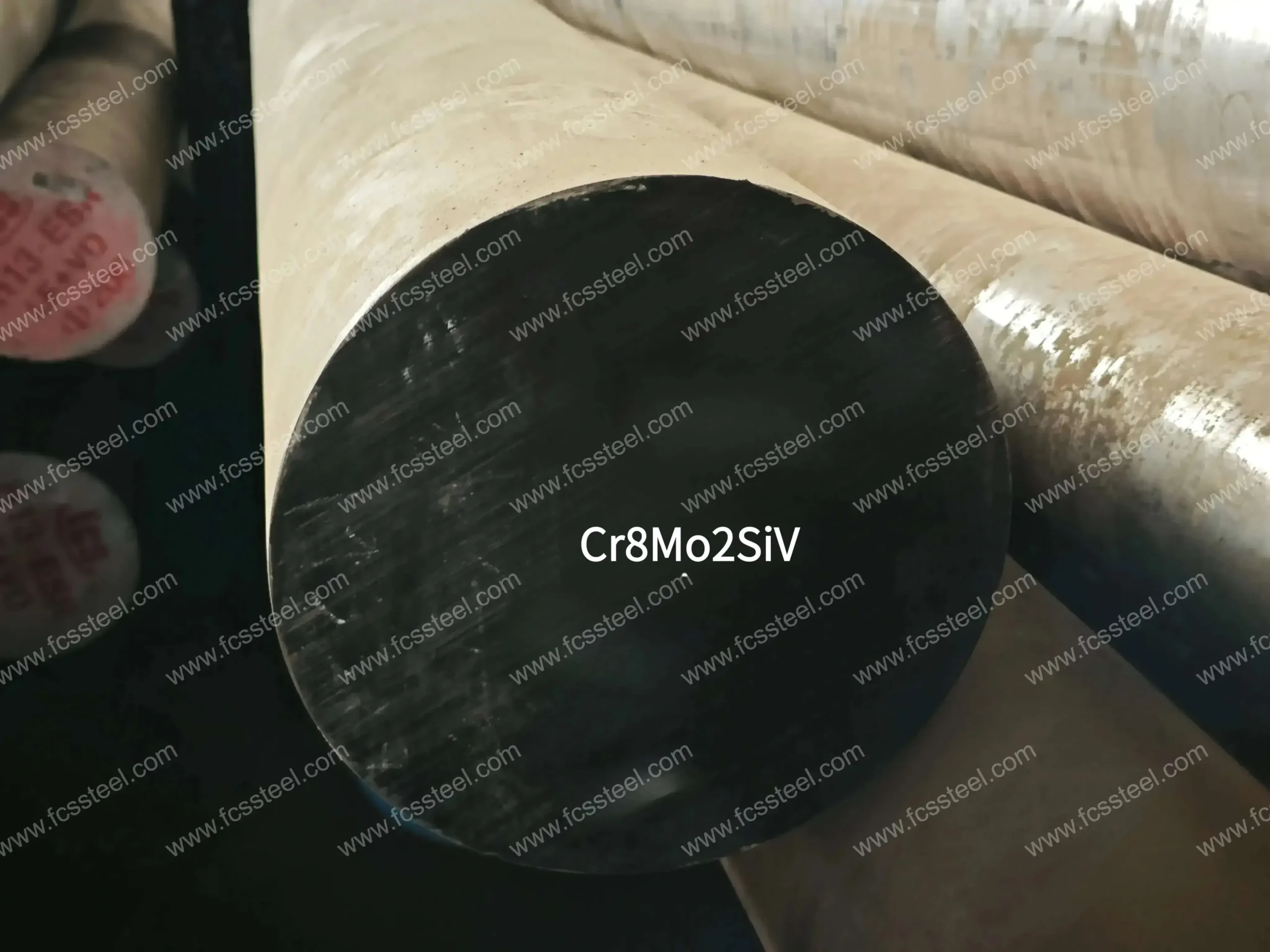

Cr8Mo2SiV Tool Steel

Cr8Mo2SiV tool steel is based on SKD11, with an optimized carbon-chromium ratio and an increased Mo/Si/V content. It not only avoids brittleness caused by coarse carbides but also performs stably in high-frequency processing, making it suitable for the manufacturing of complex cold dies and high-wear parts.

Cr8Mo2SiV Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

Cr8Mo2SiV Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

Cr8Mo2SiV Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

What is Cr8Mo2SiV Tool Steel?

Cr8Mo2SiV (also known as DC53 cold working tool steel) is a domestic high-carbon and high-chromium cold working steel. It adds molybdenum (Mo), silicon (Si), and a small amount of vanadium (V) to form fine and uniform carbides, achieving the ideal performance of both wear resistance and toughness.

International Equivalent Grades of Cr8Mo2SiV Tool Steel

Chemical Composition of Cr8Mo2SiV Tool Steel

Cr8Mo2SiV Steel Product Specifications

Cr8Mo2SiV Steel Heat treatment process and performance

- Annealing: 800-850 °C slow cooling, hardness approximately ≤255 HB (for ease of machining).

- Quenching: 1000-1040 °C oil cooling or air cooling, hardness can reach 60-63 HRC (up to 65 HRC at high end).

- Tempering: twice at 180-200 °C, maintaining high hardness; Or 400-450 °C to enhance toughness (this temperature range is suitable for tempering after processing).

- Typical properties: Excellent comprehensive fracture toughness (impact energy ≥78 J), strong resistance to plastic deformation, suitable for manufacturing heavy-duty mold parts.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |