Cr12V Tool Steel

Cr12V tool steel belongs to the same group as Cr12 / Cr12MoV/Cr12Mo1V1. Cr12V is a common extended grade in this family. The selection and acceptance follow the general terms of GB/T 1299.

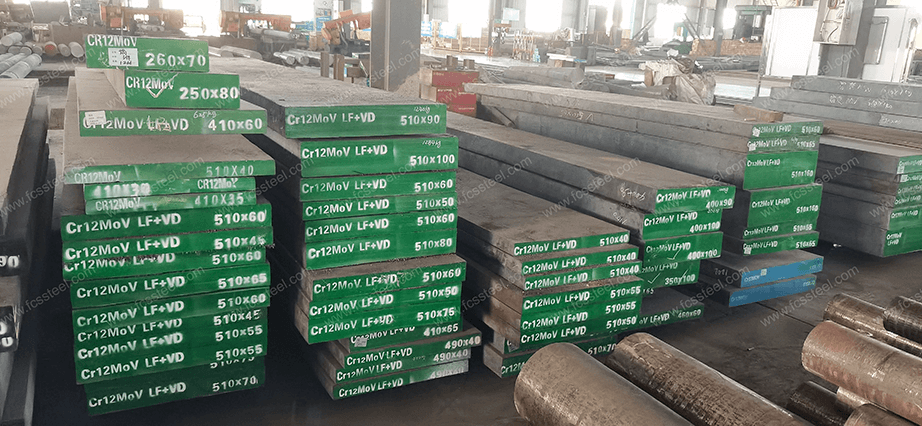

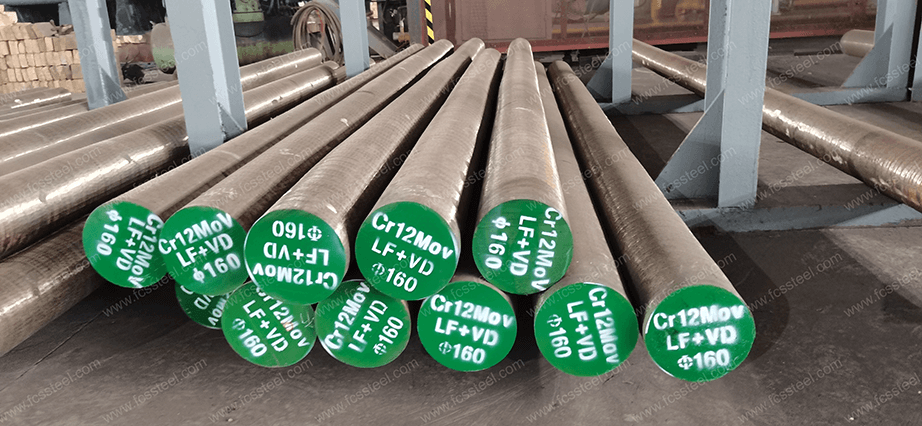

Cr12V Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

Cr12V Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

Cr12V Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

What is Cr12V Tool Steel?

Cr12V is a high-carbon and high-chromium cold working die steel. It is made by adding a small amount of V/ (and allowing trace amounts of Mo) to the traditional Cr12 system to refine carbides, enhance wear resistance and anti-chipping stability, and is suitable for cold working conditions with high wear resistance and low impact.

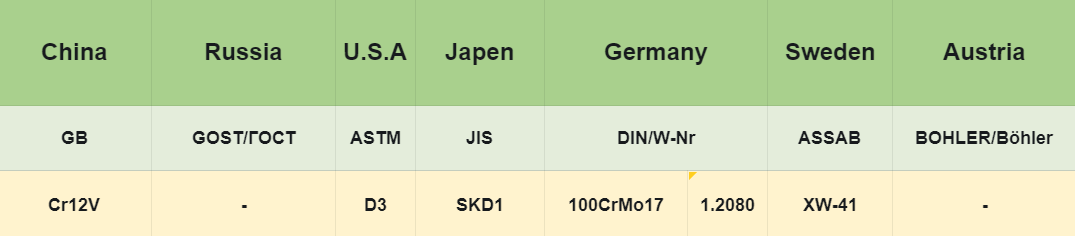

What are the international equivalent grades of Cr12V Tool Steel?

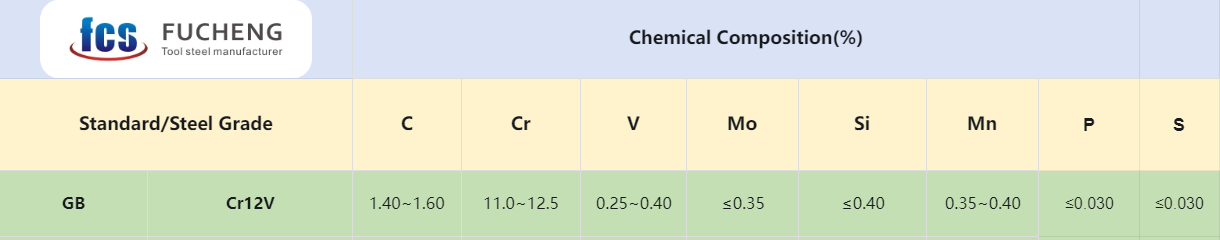

Chemical Composition of Cr12V Tool Steel

Cr12V Tool Steel:Key features

- High wear resistance and dimensional stability: V promotes the precipitation of fine Mc-type carbides, providing more stable retention of the cutting edge and cutting edge, which is positively beneficial for avoiding the collapse of the cutting edge.

- Hardenability and hardness level: Inheriting the high hardenability and high hardness baseline of the Cr12 series, it is suitable for thick cross-section cold working dies.

- Limited impact toughness: It still belongs to the "high wear resistance, low impact" scenario. In design, large impacts and sudden stress concentration should be avoided.

Cr12V Tool Steel:Typical applications

- Cold blanking/blanking/trimming dies (medium and thick plates, high-batch wear-resistant parts).

- Cold extrusion die, thread rolling plate, wire drawing die core, gauge and cold shears.

- Station inserts that require high edge retention and minimal impact.

Cr12V Tool Steel:Key points of heat treatment

The actual system must be combined with dimensions, equipment and target hardness to conduct process qualification and sample verification.

- Preheating: Staged preheating (e.g., 650-750 °C) to reduce thermal stress;

- Austenitizing: Refer to the Cr12 system ≈950-1000 °C range (oil cooling/air cooling). For thick cross-section parts, ensure adequate insulation.

- Tempering: Achieve high hardness and dimensional stability through low-temperature tempering, with 2 to 3 tempering processes.

- Target hardness: Cold working edge parts are commonly found in the range of HRC to 58-62 (subject to actual measurement).

Note: The term "secondary hardening" mentioned in some Cr12 materials for high-temperature tempering is an experience summary of different subtypes and process routes of this family. The type of tempering platform used for Cr12V should be based on the actual hardness/tempering brittleness assessment.

Comparison with other family grades (Quick Selection Overview)

- Cr12V vs Cr12 (Class D3) : Both belong to high-carbon and high-chromium cold work steels. Due to the refinement of V and the contribution of secondary hardening, Cr12V has greater potential for edge stability and wear resistance life. However, the overall shock tolerance is still limited.

- Cr12V vs Cr12MoV (D2 class) : Cr12MoV, with Mo+V toughening, has a more balanced resistance to tempering softening and hardenability, and is highly versatile. Cr12V is more inclined towards high-wear-resistant scenarios. When the working condition impact is more complex, Cr12MoV/Cr12Mo1V1 can be given priority.

Frequently Asked Questions (FAQ)

-

Q1: Can Cr12V directly replace Cr12?

A: For most high-wear-resistant and low-impact positions, Cr12V is replaceable and may lead to an increase in the life of the cutting edge. However, if the working conditions involve higher impact/complex stress, it is recommended to evaluate Cr12MoV/Cr12Mo1V1.

-

Q2: Are there any authoritative components for comparison?

A: Cr12V is a commonly used extended grade in China. There are differences in the V content range reported in the public information (0.25-0.40% and 0.70-0.90%). Please refer to the supplier's quality guarantee certificate and furnace batch inspection for accuracy.

-

Q3: Is it suitable for making thick plate blanking dies?

A: It falls within the scope of application, but it needs to be controlled according to the thick cross-section heat treatment and tempering stabilization process to avoid quenching cracking and dimensional drift.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |

.png)