Cr12MoV Tool Steel

Cr12MoV does not have a direct international equivalent number, but its performance is close to that of D2 and SKD11, and it is an important variety for substitution in the Chinese die steel market.

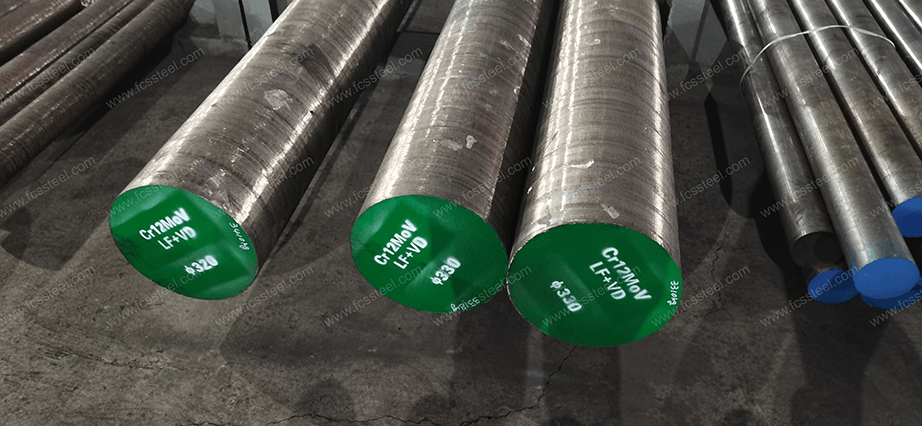

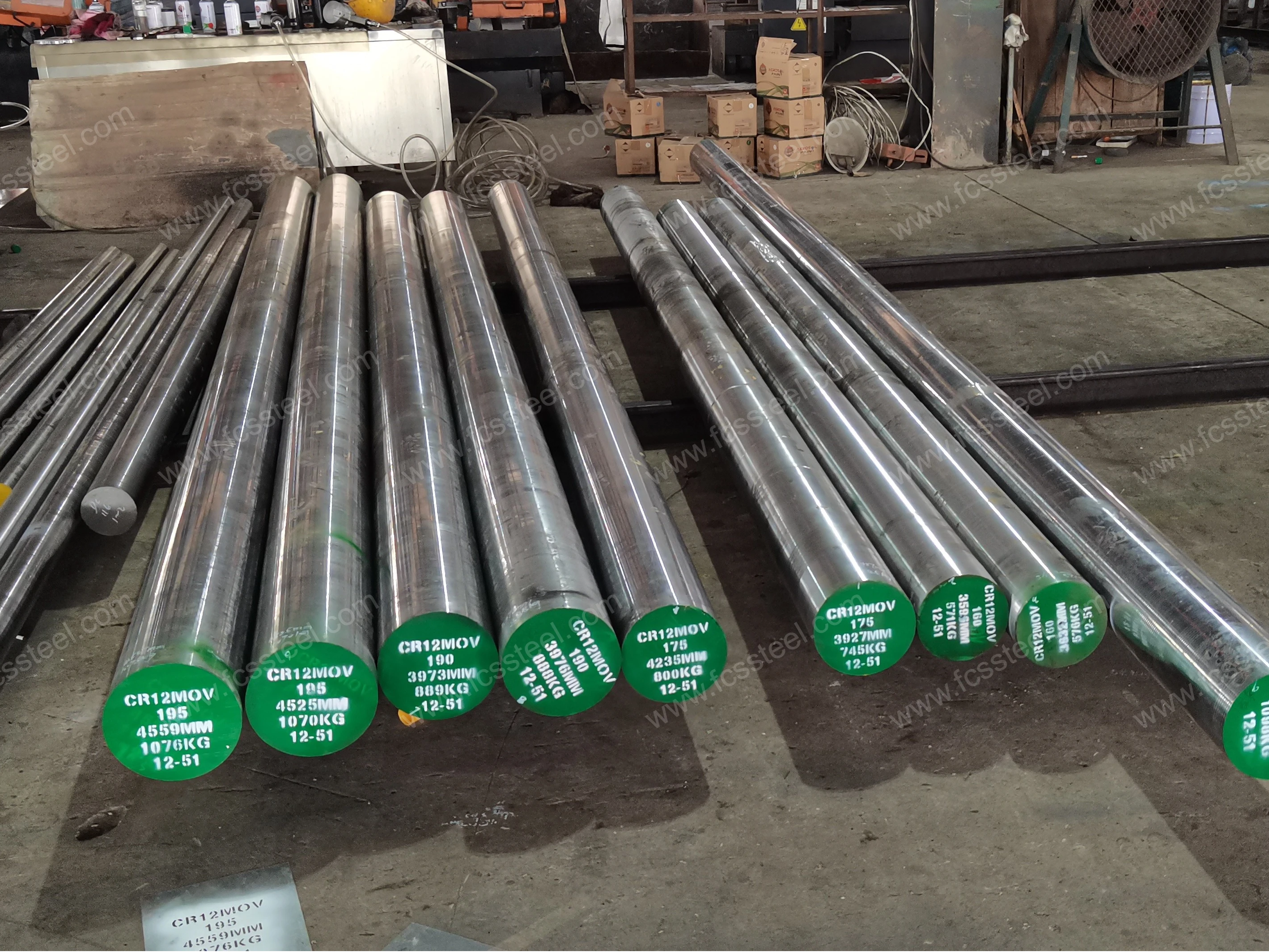

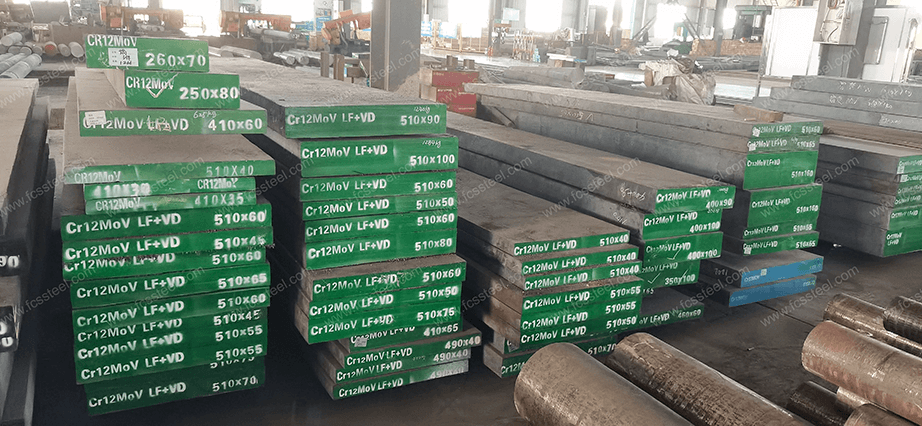

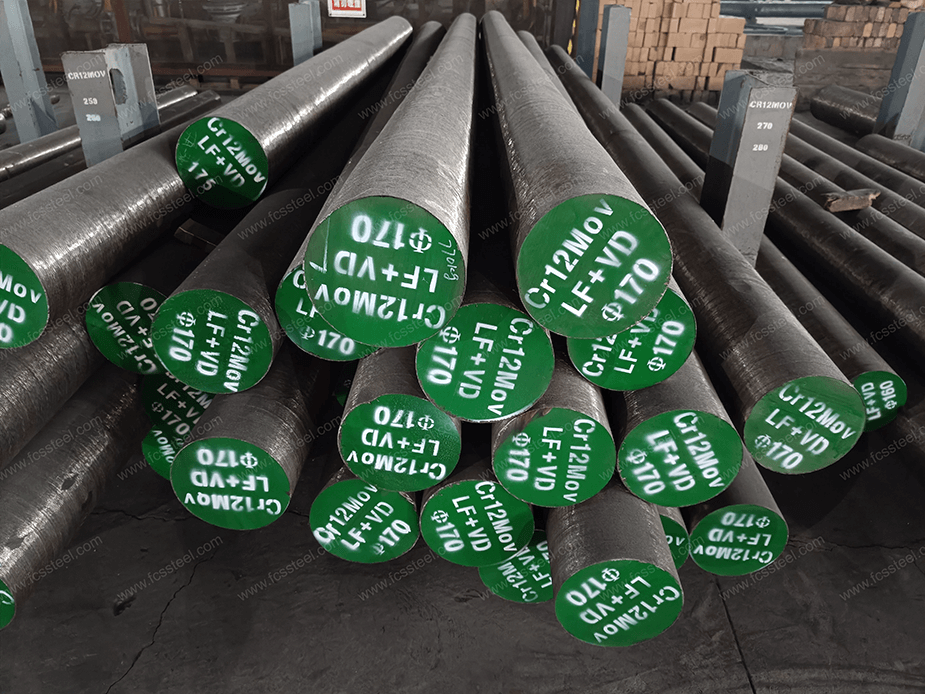

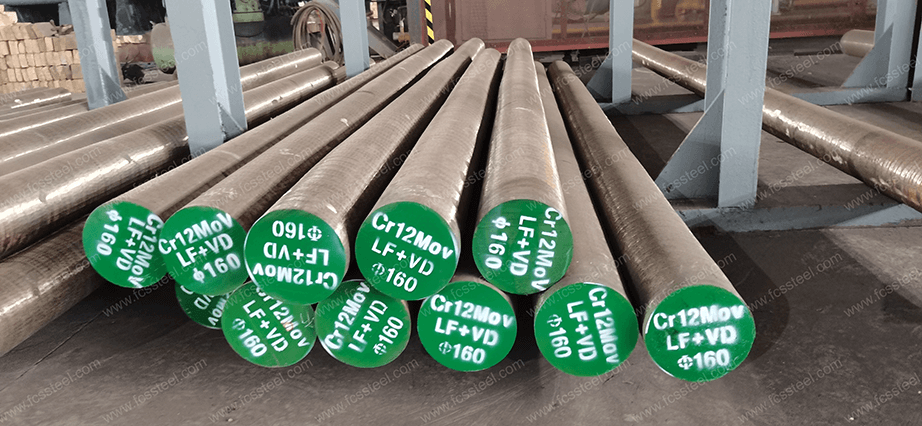

C12MoV:Product Form and Inventory Specifications

- Cr12MoV Supply status: Annealed state, machined state.

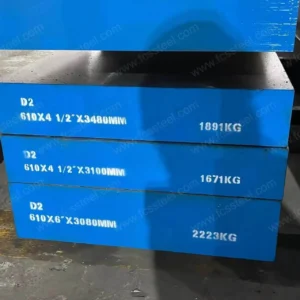

- Cr12MoV Delivery form: Round steel, plates/flat bar,custom cutting.

- Cr12MoV Processing services: sawing, rough machining, custom heat treatment.

- Cr12MoV Optional sizes: Diameter Φ10 ~ Φ65/Φ 70 ~ Φ400/500/600/700 mm,thickness 8-45/50-500mm,width 50-1000mm/50-1500mm, Forged disc ≤ 1200mm,

etc

Cr12MoV Tool Steel Forming Process Options

Cr12MoV Hot Rolled,Cr12MoV Hot Forged

Cr12MoV Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

What is Cr12MoV Tool Steel?

Cr12MoV is a commonly used cold working die steel in the Chinese national standard (GB/T 1299-2000), which is improved based on the Cr12 composition system. By introducing molybdenum (Mo) and vanadium (V) elements, its toughness, hardenability and thermal fatigue resistance have been significantly enhanced. As one of the most commonly used steel grades among domestic cold working die steels, Cr12MoV is widely applied in the manufacturing of stamping dies, shearing tools, and molds with complex structures.

It overcomes the shortcomings of Cr12 steel such as easy cracking and severe microstructure segregation, and has become a representative steel with balanced performance and price among die steels. It is especially suitable for die components with medium impact loads and long-term continuous operation.

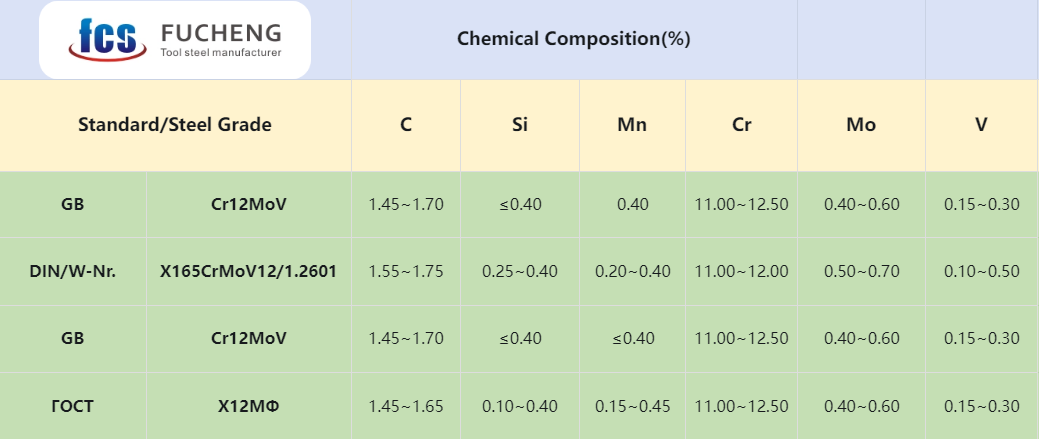

International Equivalent Grades of Cr12MoV Tool Steel

Chemical Composition of Cr12MoV Tool Steel

Cr12MoV Steel Product Specifications

Cr12MoV Steel Heat treatment

- In the annealed heat treatment state, there are no requirements for quenching temperature and tempering temperature, the hardness range is ≤255 HB, and it is characterized by being suitable for mechanical processing and pre-treatment.

- In the quenched + tempered heat treatment state, the quenching temperature is 1020~1050°C, the tempering temperature is 180~250°C, the hardness range is 58~62 HRC, and it is characterized by high hardness, good toughness and excellent thermal stability.

The application scope of Cr12MoV

Cr12MoV is an ideal material for high-frequency stamping, complex punching and shearing dies, and high-precision cold working tools. It is commonly used in:

- Precision blanking dies and shearing dies

- Cold extrusion die

- Powder metallurgy forming dies

- Roller die, thread rolling die

- High-strength punching and slotting dies

- Stamping dies for hardware, automobiles, home appliances and bearings

It is suitable for processing materials with high hardness or high wear resistance requirements such as thick plates, stainless steel sheets, and silicon steel sheets.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 180 × 40 × 30 cm |

.png)