Cr12 Tool Steel

Cr12 is similar to D3 and 1.2080, but there are slight differences in impurity control and heat treatment response.

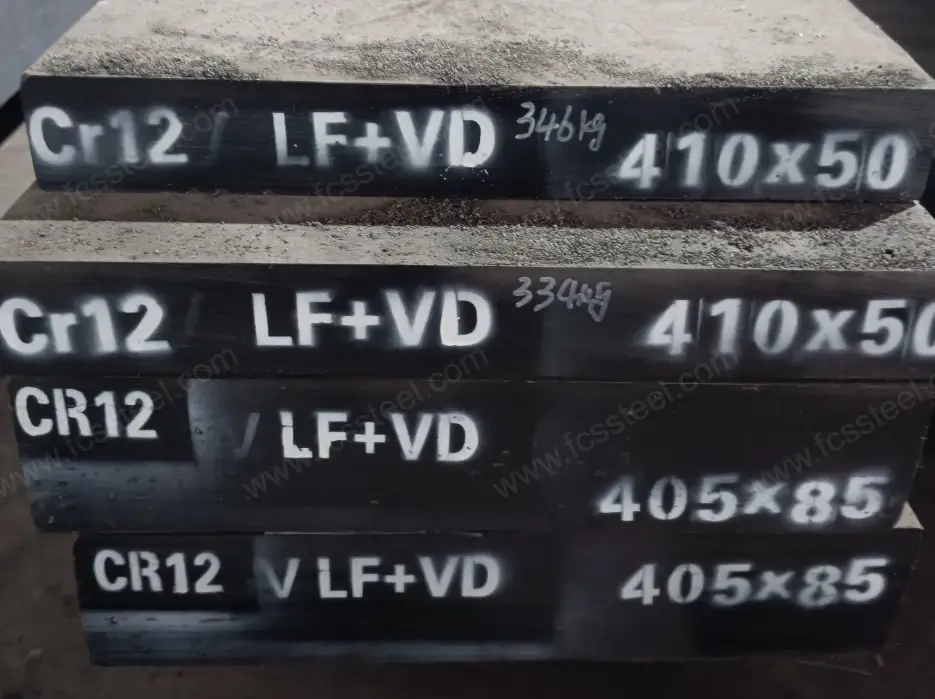

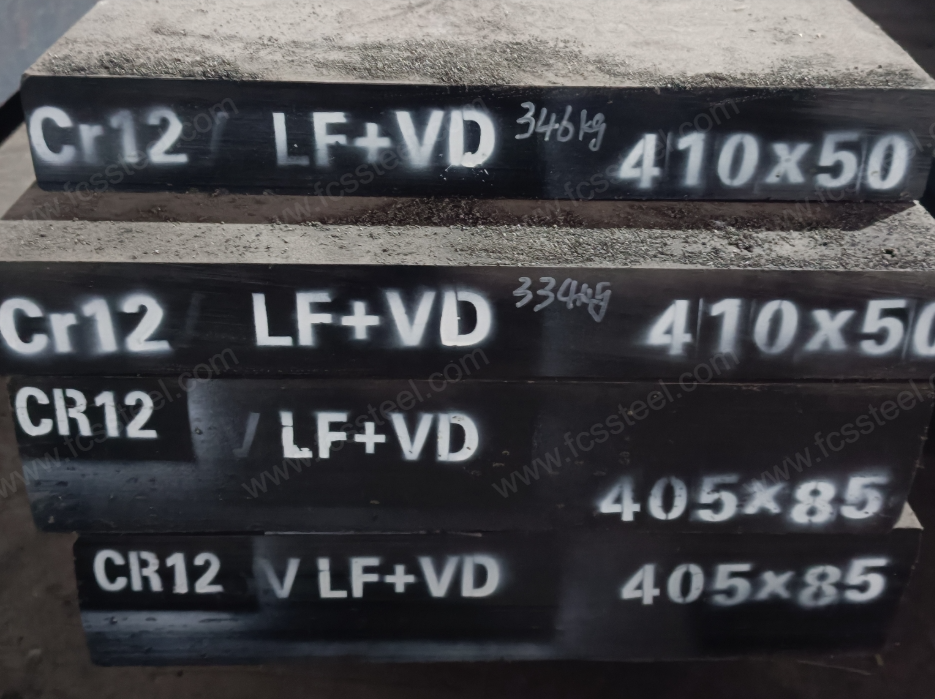

C12:Product Form and Inventory Specifications

- Cr12 Supply status: Annealed state, machined state.

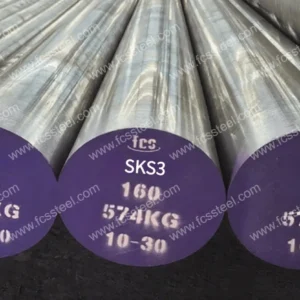

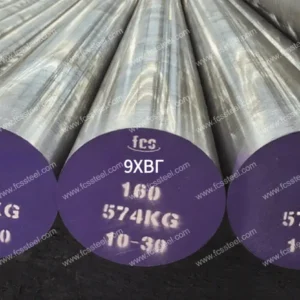

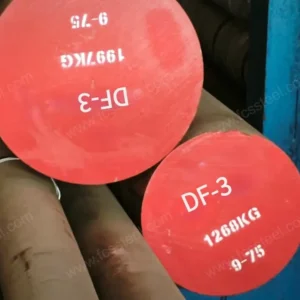

- Cr12 Delivery form: Round steel, plates/flat bar,custom cutting.

- Cr12 Processing services: sawing, rough machining, custom heat treatment.

- Cr12 Optional sizes: Diameter Φ10 ~ Φ65/Φ 70 ~ Φ400/500/600/700 mm,thickness 8-45/50-500mm,width 50-1000mm/50-1500mm, Forged disc ≤ 1200mm,

etc

Cr12 Tool Steel Forming Process Options

Cr12 Hot Rolled,Cr12 Hot Forged

Cr12 Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

What is Cr12 Tool Steel?

Cr12 is a high-carbon and high-chromium cold-work tool steel widely used in China's GB standard, belonging to ledeburitic alloy tool steel. It is renowned for its excellent wear resistance, high hardness, and good hardenability, and is suitable for manufacturing high-precision, long-life cold-work dies. Its performance is close to the internationally renowned D3 (AISI) and 1.2080 (DIN) steel grades, but it has more advantages in cost control and localized supply.

After heat treatment, this steel has significant hardness and dimensional stability, and can maintain good wear resistance even under high-load friction conditions. It is an ideal material for cold stamping dies, cold scissors, deep drawing dies, roller dies, powder pressing dies, etc.

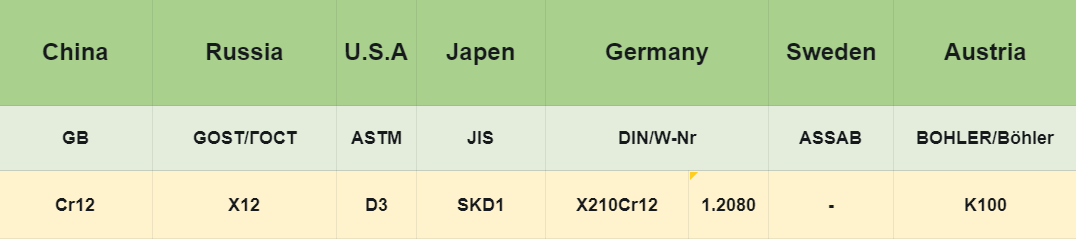

International Equivalent Grades of Cr12 Tool Steel

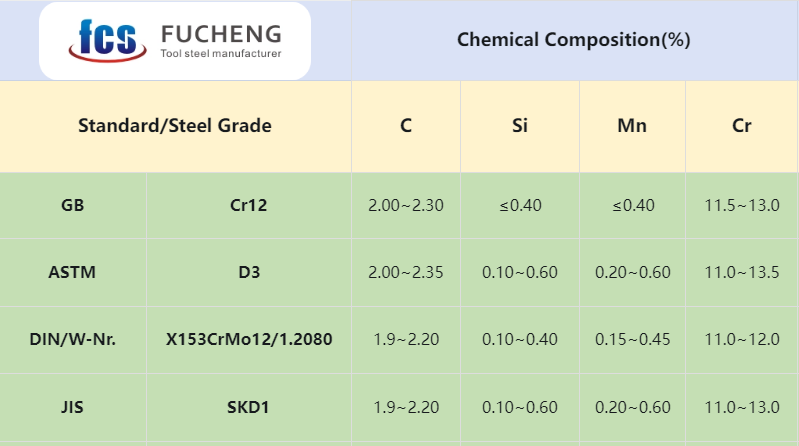

Chemical Composition of Cr12 Tool Steel

Heat treatment and performance parameters

- Annealed Hardness:≤255 HB

- Quenching Temperature:1000~1050°C

- Tempering Temperature:180~200°C

- Hardness after Quenching and Tempering:60~63 HRC

- Brief Characteristics:High hardness, extremely wear-resistant, low toughness.

- Annealing recommendation: Cool slowly at 800 to 850°C to achieve better machinability.

- Quenching recommendation: Oil cooling or air cooling, followed by low-temperature tempering.

- Note: Multiple tempering can reduce the risk of quenching cracks.

Typical application scenarios

Cr12 is widely used in the manufacture of various cold working dies, especially suitable for large-scale production and high-wear applications, such as

- Stamping dies, shearing dies

- Powder metallurgy die pressing

- Cold forging dies

- Cold roller press wheels, embossing dies

- Precision gauges and tools

In cases where higher toughness or crack resistance is required, it is recommended to switch to series such as Cr12MoV, DC53 tool steelor K110 tool steel.

Cr12 Steel Product Specifications

Relevant inspections and standards

- Standard implementation: GB/T 1299 General Technical Conditions for Tool Steel.

- UT flaw detection: Qualified in accordance with D/d grade.

- Chemical analysis: Spectrometer.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |