A2 Tool Steel

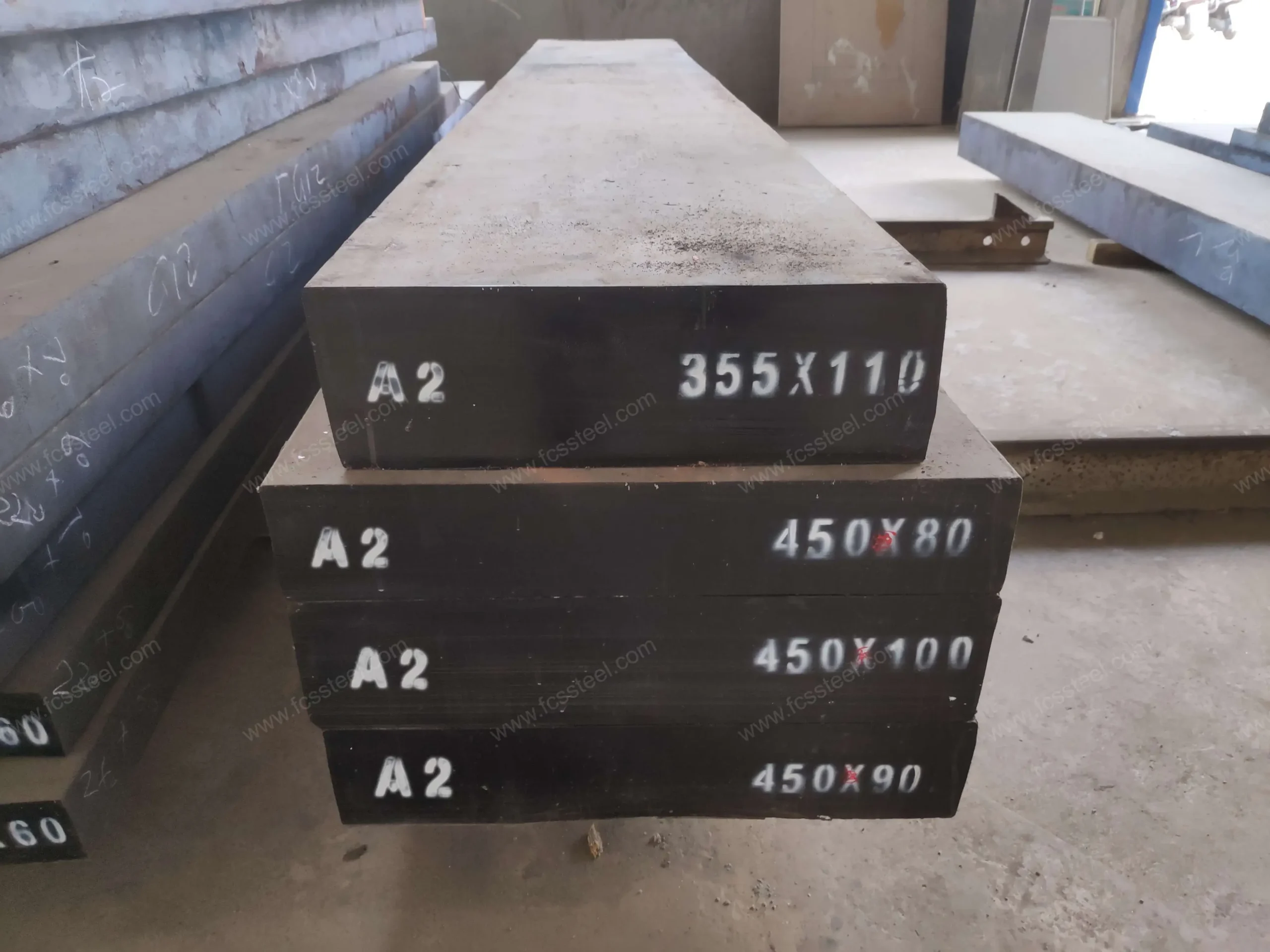

FCS Tool Steel provides ready-to-ship A2 Tool Steel in multiple shapes and sizes:

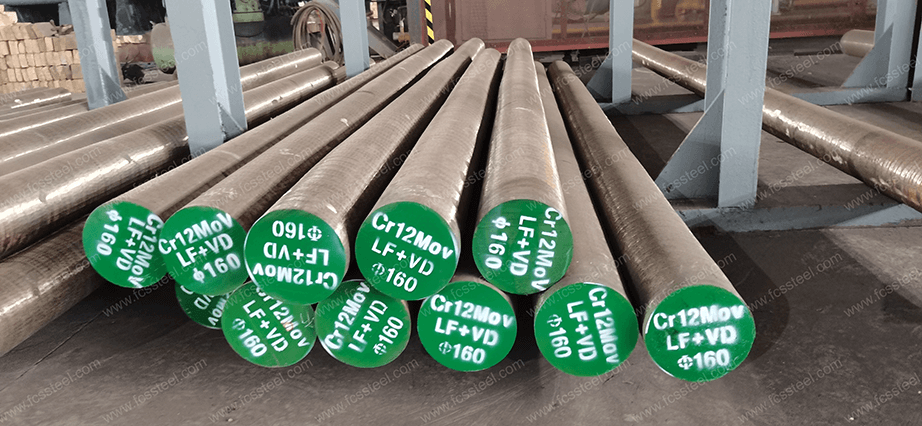

- A2 Tool Steel Round Bars → The surface condition can be selected as black skin, peeled skin or car finish.

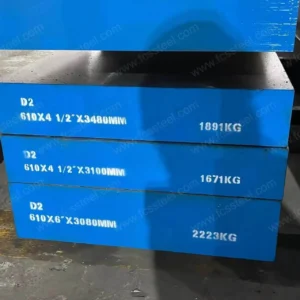

- A2 Flat Bars & Plates → Annealed state is available. The surface condition can be selected as black skin, sandblasted or milled.

- Custom Cut Sizes → tailored dimensions for immediate machining.

FCS’s warehouse maintains large inventory stock to guarantee fast global dispatch.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

Overview of A2 Tool Steel

A2 Tool Steel, designated under AISI classification, is an air-hardening cold work tool steel with high wear resistance and excellent dimensional stability during heat treatment. It is widely used in stamping dies, forming tools, and cutting instruments. Compared with oil-hardening O1 steel, A2 offers better toughness and stability, making it one of the most popular choices for precision tooling.

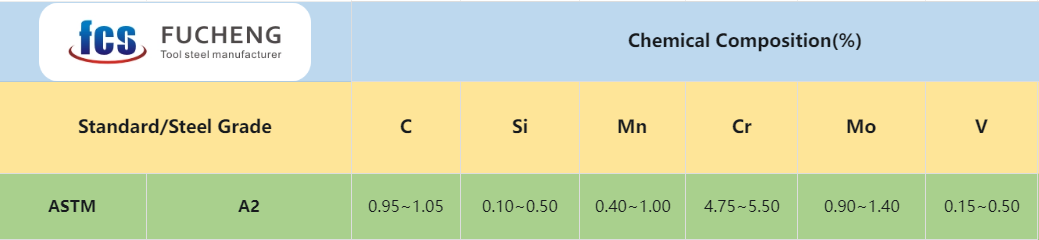

A2 Tool Steel:Chemical Composition (Typical, %)

- C (Carbon): 0.95 – 1.05

- Cr (Chromium): 4.75 – 5.50

- Mo (Molybdenum): 0.90 – 1.40

- Mn (Manganese): 0.40 – 1.00

- V (Vanadium): 0.15 – 0.50

- Si (Silicon): 0.10-0.50

This alloy balance provides excellent hardness (up to 62 HRC after hardening) and reliable wear resistance while retaining reasonable toughness.

A2 Tool Steel:Key Features

- Air-hardening steel → reduces risk of cracking or distortion during quenching.

- Good dimensional stability → suitable for precision dies and tools.

- Balanced wear resistance and toughness → better than O1, less brittle than D2.

- Ease of machining (annealed condition) → allows efficient tool manufacturing.

- Long service life in tooling applications under moderate to high stress.

A2 Tool Steel:Heat Treatment Process

- Annealing: Heat to 845–870°C, then slow cool at ≤20°C per hour to 650°C.

- Hardening: Preheat at 790–820°C, then austenitize at 955–980°C.

- Quenching: Air or inert gas cooling.

- Tempering: Usually double tempering at 150–500°C depending on required hardness (final hardness 57–62 HRC).

Applications of A2 Tool Steel

- Blanking & Punching Dies

- Cold Shear Blades

- Forming and Bending Tools

- Gauges & Fixtures

- Knives and Cutting Tools

- Industrial Shears

A2 steel is especially popular in general-purpose cold work tooling where both durability and dimensional accuracy are required.

Why Choose FCS Tool Steel as Your A2 Supplier?

- Direct Factory Source → competitive wholesale pricing.

- Strict Quality Control → every batch meets ASTM/AISI specifications.

- Global Shipping → efficient logistics covering Europe, Asia, and North America.

- Customization Service → size cutting and special heat treatment available.

- Trusted by Distributors & Traders worldwide.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |

.png)

-1-300x300.png)