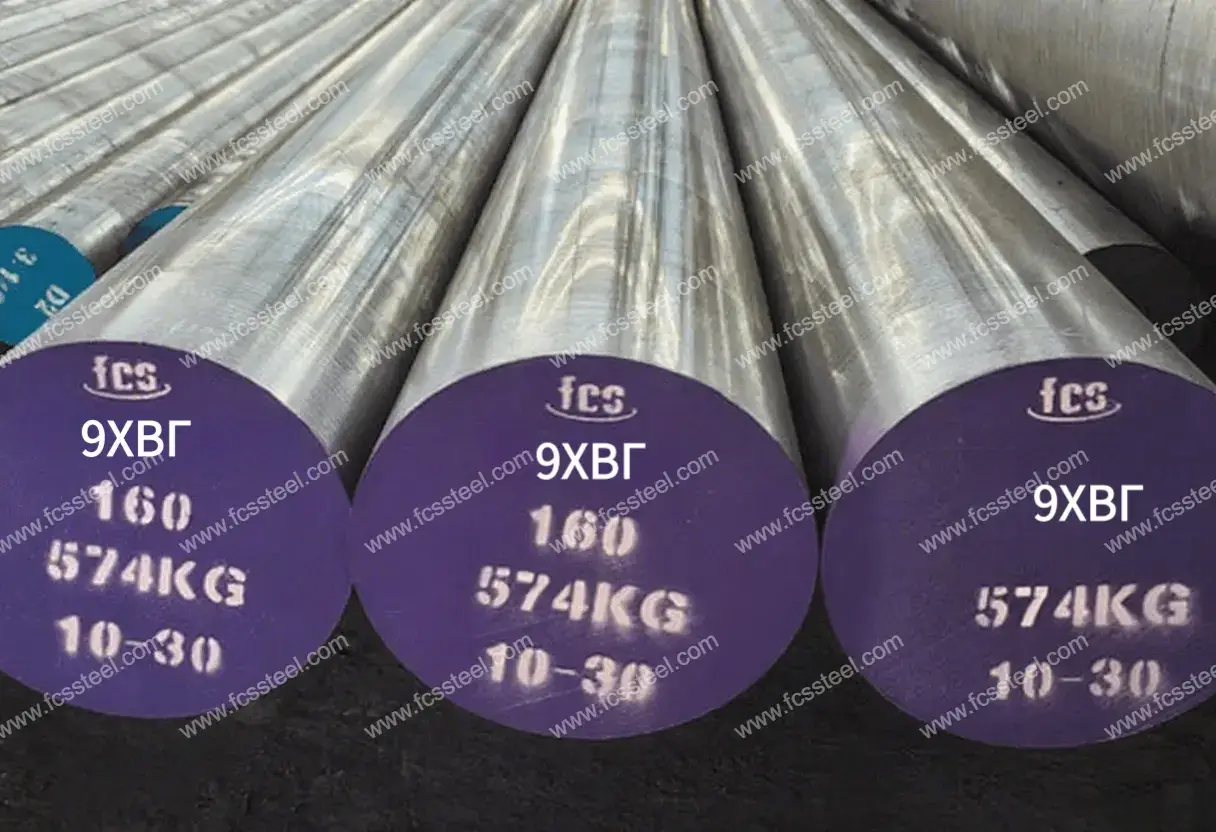

9XBГ Tool Steel

9XBГ tool steel is a high performance cold work mould steel with excellent wear resistance, high hardness and good heat treatment stability. The corresponding ASTM standard is O1 tool steel, and the corresponding DIN/W-Nr standard is 100MnCrW4. 9XBГ tool steel is especially suitable for stamping moulds, precision gauges, demanding cutting tools, and all kinds of industrial moulds. 9XBГ tool steel can be supplied with a wide range of specifications and customized machining services to meet the stringent process requirements of different manufacturers. FCS Tool Steel Factory offers a wide range of specifications and custom machining services to meet the stringent process requirements of different manufacturers.

9XBГ Tool Steel Product Introduction

9XBГ tool steel is a tungsten-alloyed medium-carbon tool steel according to the Russian ГОСТ standard, classified as an impact-resistant alloy tool steel. Its chemical composition is based on medium-high carbon (C: 0.55-0.65%), supplemented by chromium (Cr: 1.00-1.30%), tungsten (W: 2.00-2.70%), silicon (Si: 0.50-0.80%), manganese (Mn ≤ 0.40%) and other elements. Mn ≤ 0.40%) and other elements, strict control of phosphorus and sulfur impurities (all ≤ 0.030%). The annealed hardness of the steel is 229-285 HB, density of about 7.85 g/cm³, with excellent hardenability (oil quenching and hardening depth is uniform) and high temperature strength retention ability (400 ℃ still maintain high hardness), while the tungsten element through the refinement of grain toughness to enhance the reduction of the risk of brittle cracking in the impact of the working conditions, but the thermal conductivity is relatively low (about 24.3 W / (m)), and the thermal conductivity is low (about 24.3 W / (m)). -K), which may accumulate thermal stresses during rapid thermal cycling.

By oil quenching and hardening (860-900°C) with low to medium temperature tempering (150-400°C), 9XBГ can be optimised to a hardness of ≥57 HRC, a tensile strength of ≥672 MPa, a yield strength of ≥472 MPa, and the formation of a predominantly tempered martensitic organisation. The nature of the design relies on tungsten carbides to enhance wear resistance and the chromium-silicon composite to balance strength and plasticity, but the risk of grain boundary impurity bias needs to be modulated by the heat treatment process to maintain high temperature stability.

9XBГ Tool Steel Types and Options

The table below shows the size range, surface condition and tolerance details for 9XBГ Tool Steel:

9XBГ Tool Steel Customized Options

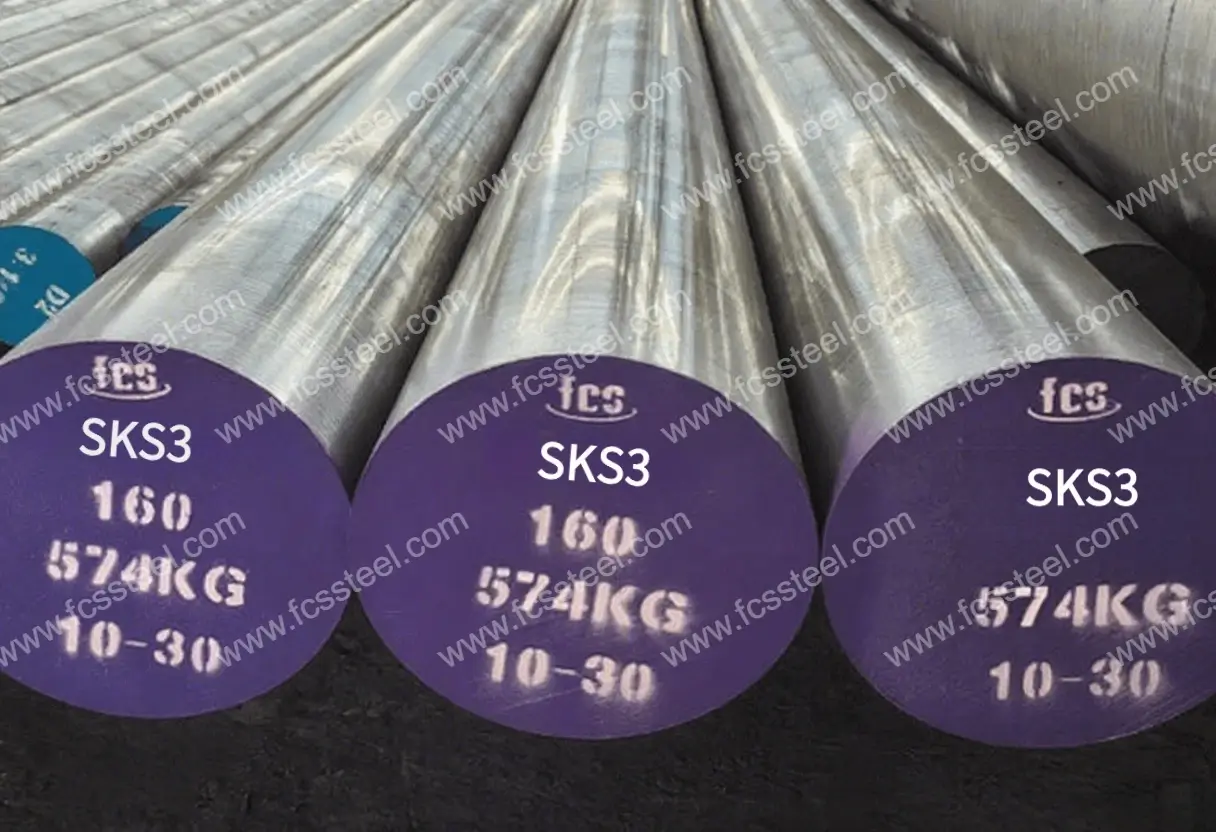

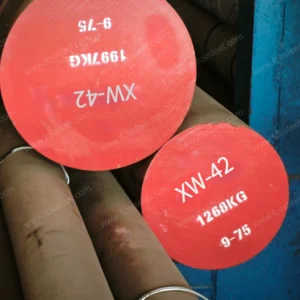

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- 9XBГ Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

9XBГ Tool Steel Chemical Composition

9XBГ Tool Steel Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

9XBГ Tool Steel Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

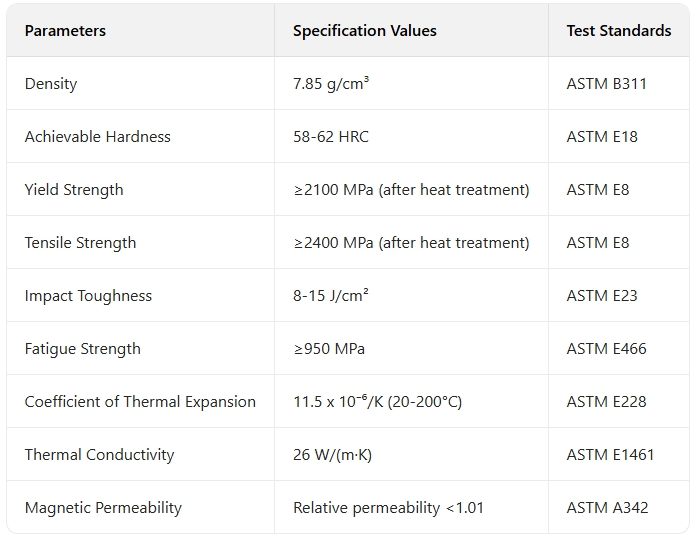

9XBГ Tool Steel Technical Specifications

9XBГ Tool Steel Product Applications

Automotive Manufacturing

- Engine Parts Stamping Mould

- Body High Strength Steel Plate Forming Mould

- Transmission Gear Stamping and Shaping Tools

- Precision Inspection Gauges and Measuring Tooling

Aerospace

- Titanium and high-temperature alloy forming tools

- Precision sheet metal forming moulds

- High-precision inspection equipment components

- Composite material processing cutting tools

Electrical and Electronic Industry

- Precision Connector Stamping Moulds

- Micro Electronic Component Forming Tools

- Precision Heat Sink Stamping and Forming Moulds

- Precision Electronic Housing Stamping Tools

Medical Device Manufacturing

- Precision Medical Device Component Forming Moulds

- Medical Implant Processing Tools

- Precision Syringe Component Stamping Moulds

- Surgical Tool Manufacturing

Energy equipment manufacturing

- High-pressure valve parts processing tools

- Precision gear processing tools for wind power equipment

- Wear-resistant parts for oil and gas extraction equipment

- Precision component moulds for power equipment

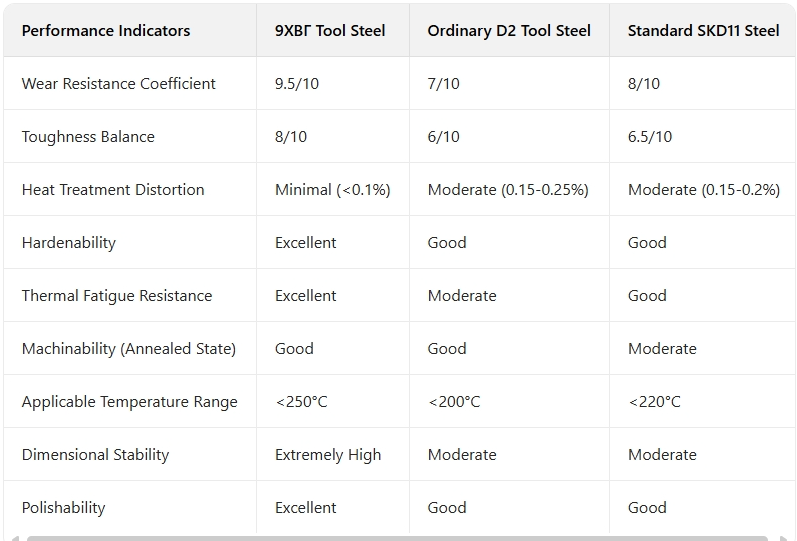

9XBГ Tool Steel Competitive Advantage Comparison

9XBГ Tool Steel Customer Success Stories

9XBГ Tool Steel Pricing Structure Information

9XBГ Tool Steel Frequently Asked Questions

Q1: What are the main advantages of 9XBГ tool steel compared to normal D2 tool steel?

A1: The main advantages of 9XBГ tool steel are higher wear resistance (up to 30%), better toughness balance, lower heat treatment distortion (typically <0.1%) and higher dimensional stability. These properties make it an excellent performer in high-precision moulding and long-life tooling applications. The tungsten element in 9XBГ provides better thermal stability and secondary hardening compared to D2.Q2: Why does 9XBГ tool steel have less heat treatment distortion?

A2: The low heat treatment distortion of 9XBГ tool steel is mainly due to its homogeneous distribution of alloying elements and special heat treatment process. The addition of tungsten slows down the rate of martensitic transformation and makes it more homogeneous. Meanwhile, our recommended multi-stage preheating and precise temperature-controlled heat treatment process significantly reduces the accumulation of internal stresses, which in turn reduces the risk of distortion.Q: What are the storage and handling precautions for 9XBГ tool steel?

A: The storage environment should be dry and free from severe temperature changes and humidity. For long term storage it is recommended to apply rust inhibiting oil and pack in moisture proof packaging. In the process of machining, for large workpieces, attention should be paid to the uniform force and support to avoid deformation caused by self-weight. Before heat treatment, oil and oxidised layer should be removed from the surface to ensure even heating.Q: How does 9XBГ tool steel compare with imported brand tool steel?

A: The properties of 9XBГ tool steel are comparable to those of UDDEHOLM's SVERKER 21 from Sweden, D2 from the USA and SKD11 from Japan, and in some cases even better in terms of properties such as heat treatment distortion control and toughness balance. We adopt strict quality control and advanced smelting process to ensure the consistency and reliability of the material performance to meet the international level.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |