9SiCr Tool Steel

At FCS Tool Steel, we offer 9SiCr Tool Steel in multiple supply conditions:

Supply Condition:Annealed,Machined

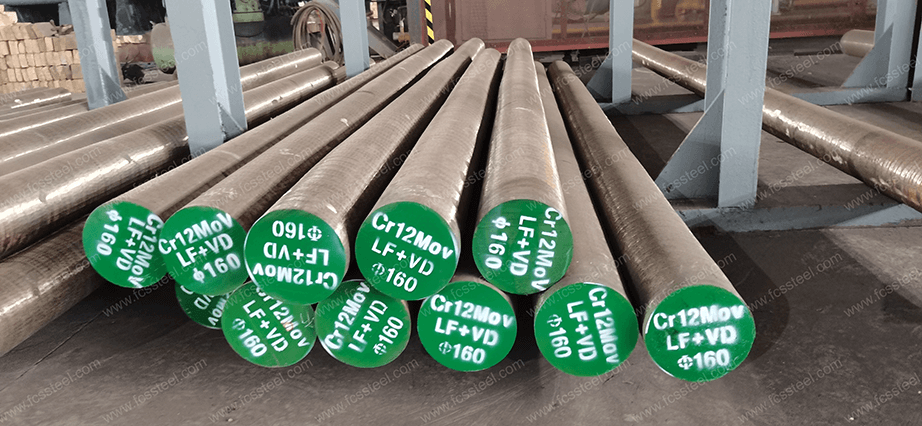

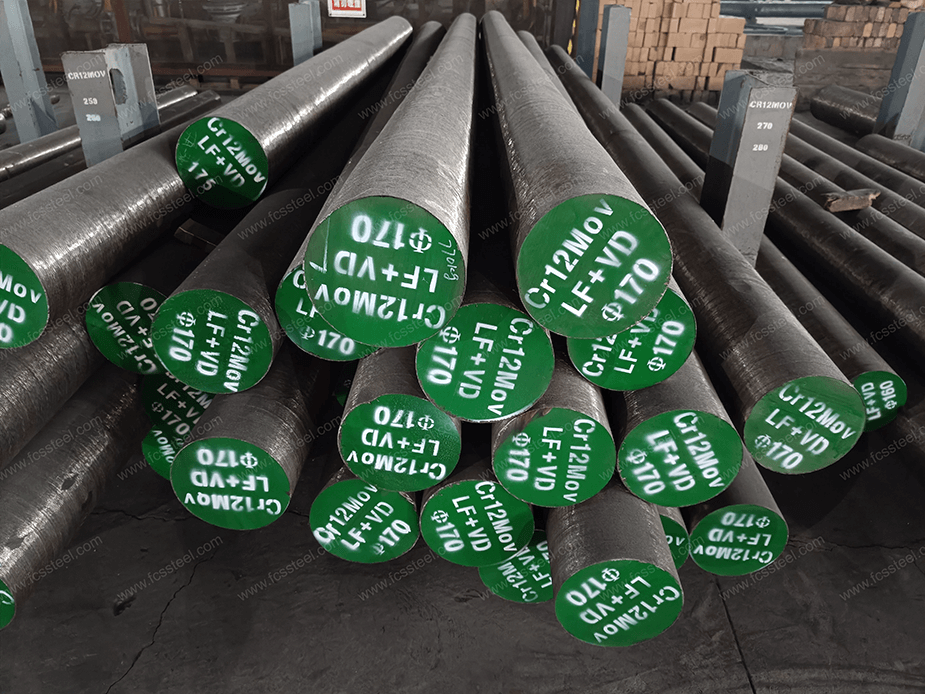

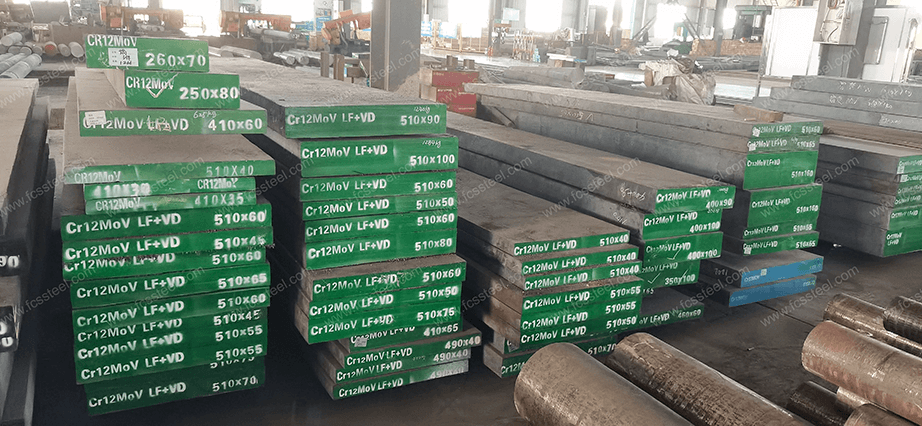

Available Forms:Round bars,Plates / Flat bars,Custom-cut pieces

Processing Services:Sawing,Rough machining,Custom heat treatment.

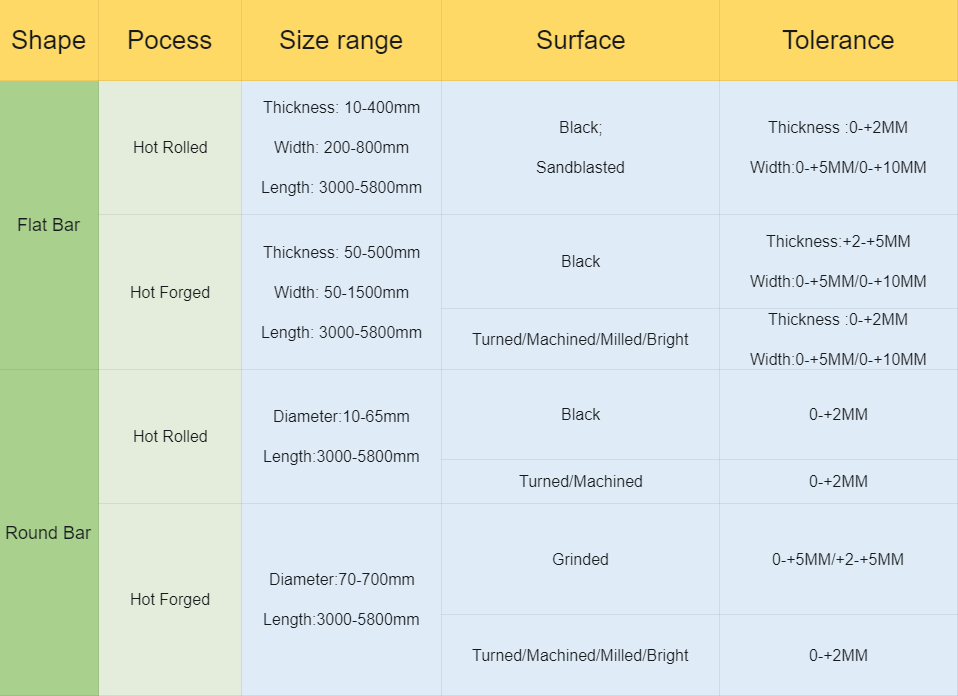

Standard Size Range (Availability varies by stock):

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

Forming Methods:Hot Rolled,Hot Forged.

Surface Finish Options:Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

9SiCr Tool Steel:Material Introduction

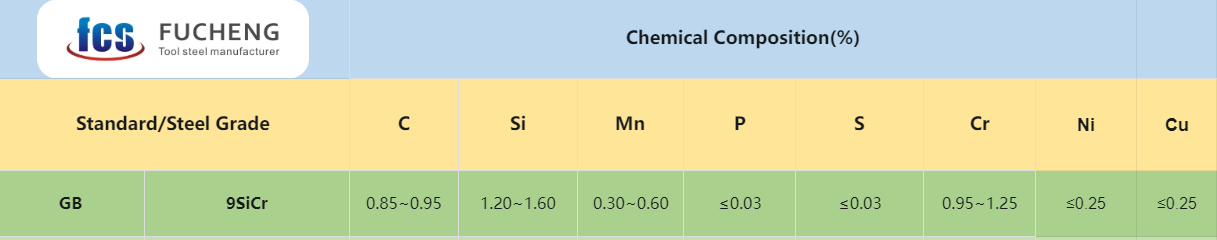

9SiCr is a low alloy cold work tool steel containing approximately 0.85-0.95% carbon, 1.20-1.60% silicon and 0.95-1.25% chromium. Its excellent hardenability, high tempering stability and wear resistance make it widely used in cold forming tools, blanking parts and measuring tools. This grade originated in the former Soviet Union (referred to as 9XC) and has a long history of application in China.

9SiCr Tool Steel:Product Specification

9SiCr Tool Steel:Chemical Composition

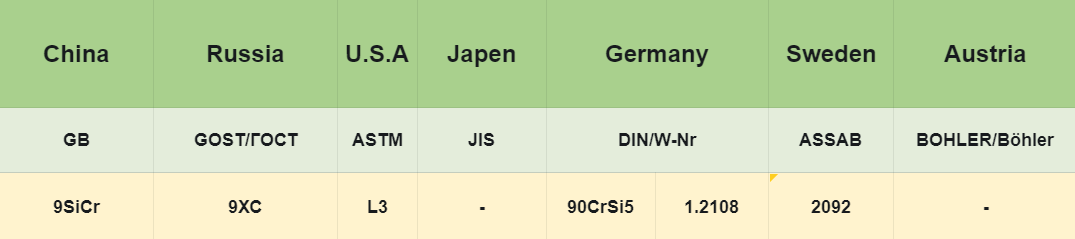

9SiCr Tool Steel:International equivalent grade

In international materials, 9SiCr is compared with the following grades as follows:

9SiCr Tool Steel:Main characteristics and heat treatment advantages

- High hardenability: It hardens more deeply than standard chromium steel (such as Cr2).

- Tempering temperature stability: Hardness recovery is smoother, and the risk of tempering cracks is low.

- Good wear resistance: Suitable for high-precision tools and blanking parts;

- Excellent quenchability and fine microstructure: The morphology of carbides remains stable after heat treatment.

9SiCr Tool Steel:Typical machinery and application performance

Hardness (quenched state) : Up to HRC ≥62 (oil-cooled); The tempered hardness is stable at HRC ~59-63.

Low dimensional deformation under stress: Suitable for complex-shaped mold parts.

Common uses

- Cold blanking dies (cutting, trimming, punching);

- Drawing/wire drawing die core;

- Cold head forging and stamping parts, small rolling/stamping tools, etc.

9SiCr Tool Steel:Heat Treatment Guidance

- Annealing: Hold at 780-810 °C → slowly cool in the furnace to 550 °C and then air cool, which can achieve ~197-241 HBW.

- Quenching: Heat to 860-880 °C → Oil cooling or salt bath quenching → Hardness reaches HRC 62-65. Subsequent optional cold treatment at -70 °C can enhance dimensional stability.

- Tempering: It is recommended to temper at 180-220 °C for stress relief. High-precision parts can be tempered at a temperature of ≤200 °C.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 180 × 135 cm |

.png)

-1-300x300.png)