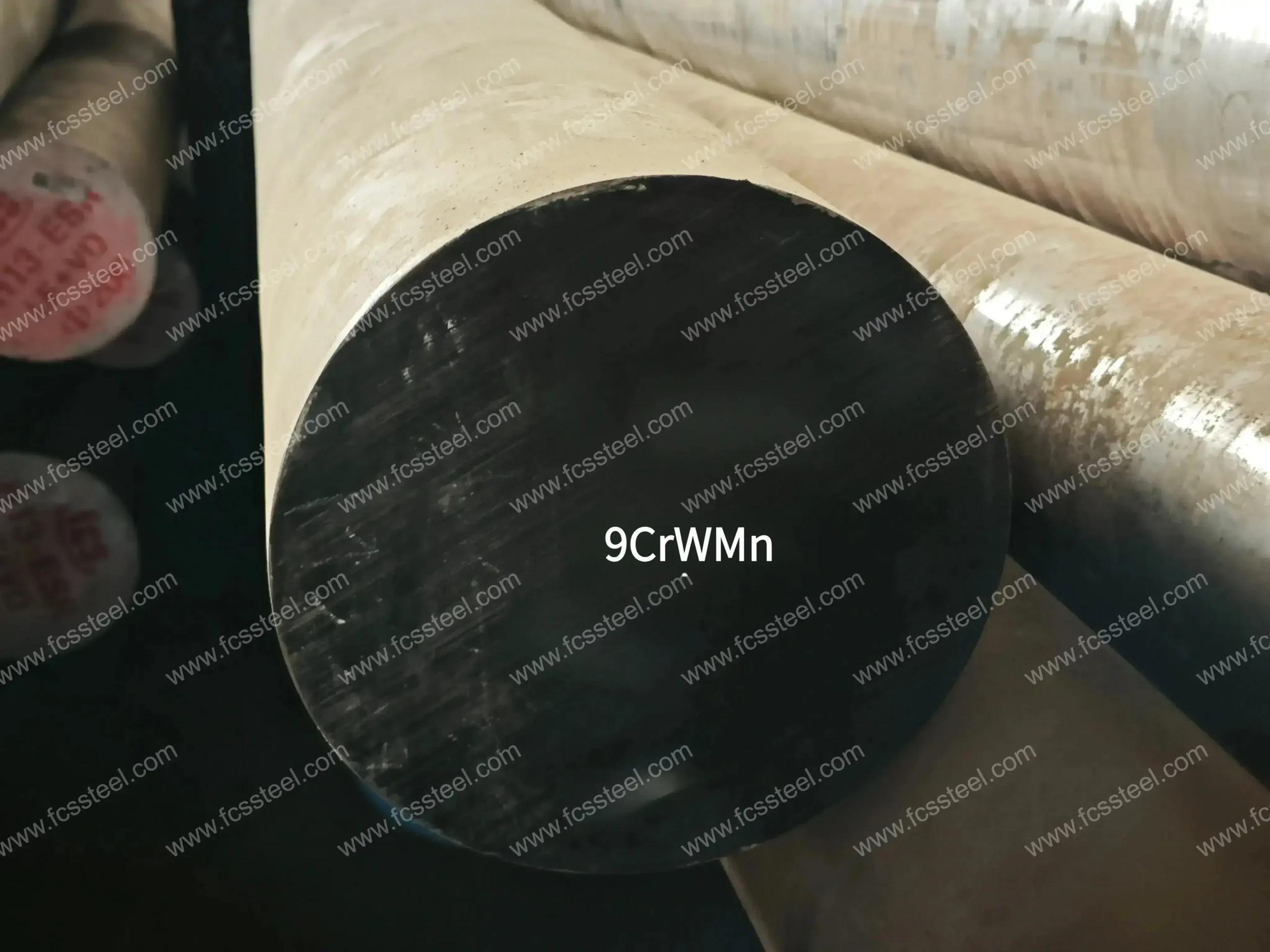

9CrWMn Tool Steel

9CrWMn tool steel features excellent wear resistance and quenching stability. It is suitable for cold working die parts with complex shapes, small cross-sections and high precision requirements.

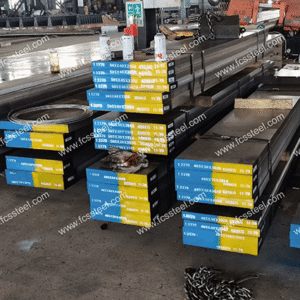

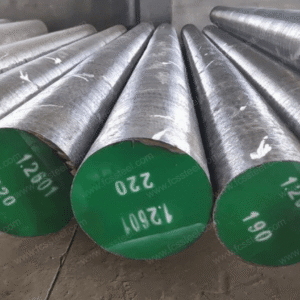

9CrWMn Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

9CrWMn Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

9CrWMn Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

What is 9CrWMn Tool Steel?

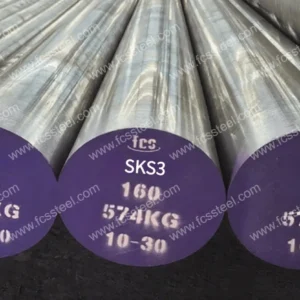

9CrWMn is a low alloy cold working tool steel in the Chinese GB/T 1299 standard, also known as GB-9CrWMN or SKS3 (DIN 1.2510 / AISI O1).

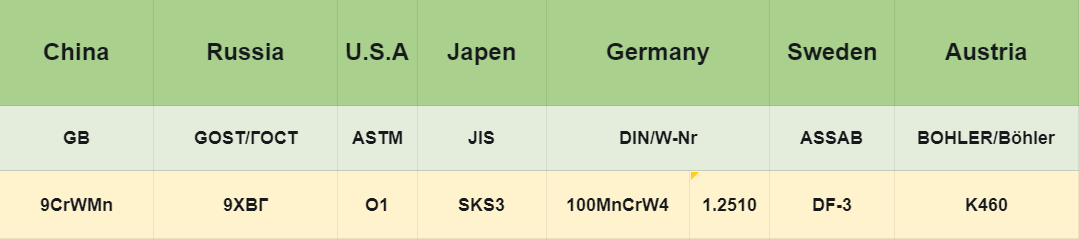

International Equivalent Grades of 9CrWMn Tool Steel

Chemical Composition of 9CrWMn Tool Steel

9CrWMn Steel Product Specifications

9CrWMn Steel Heat Treatment Process and Properties

- Annealing: Hold at 780-800 °C and cool slowly (≤50 °C/hr), with a hardness of approximately 200-240 HB.

- Quenching: 860-900 °C oil cooling, hardness can reach 60-64 HRC; The hardness of large parts is slightly lower (about 57 HRC).

- Tempering: Commonly used is 200-250 °C (to stabilize hardness), or toughened to 400-450 °C; Avoid the tempering brittleness temperature range (300-350 °C).

9CrWMn Steel Main performance characteristics

- It has a high quenched hardness of up to 64 HRC, making it suitable for high-wear scenarios.

- It has small cold deformation and excellent dimensional stability.

- The fine and uniform carbides enhance the overall toughness.

- It has a relatively low impact sensitivity, but sudden cooling cracking still needs to be avoided.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |