9Cr18 Stainless Steel

9Cr18 (also marked as 95Cr18) is usually close in performance and composition to AISI 440 series (especially 440A/440B/440C) or similar martensitic stainless steels. Variants containing Mo/V can be closer to the behavior of 440C. Equivalence does not mean strict equalization. The actual material selection should still be based on the composition and heat treatment targets.

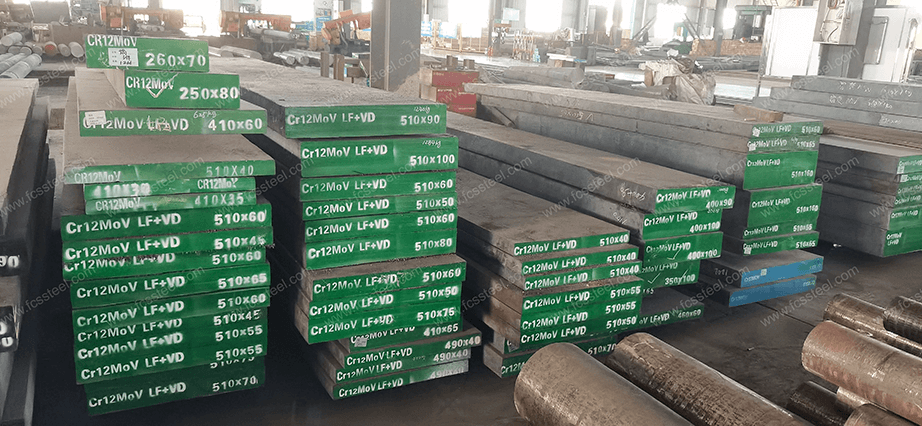

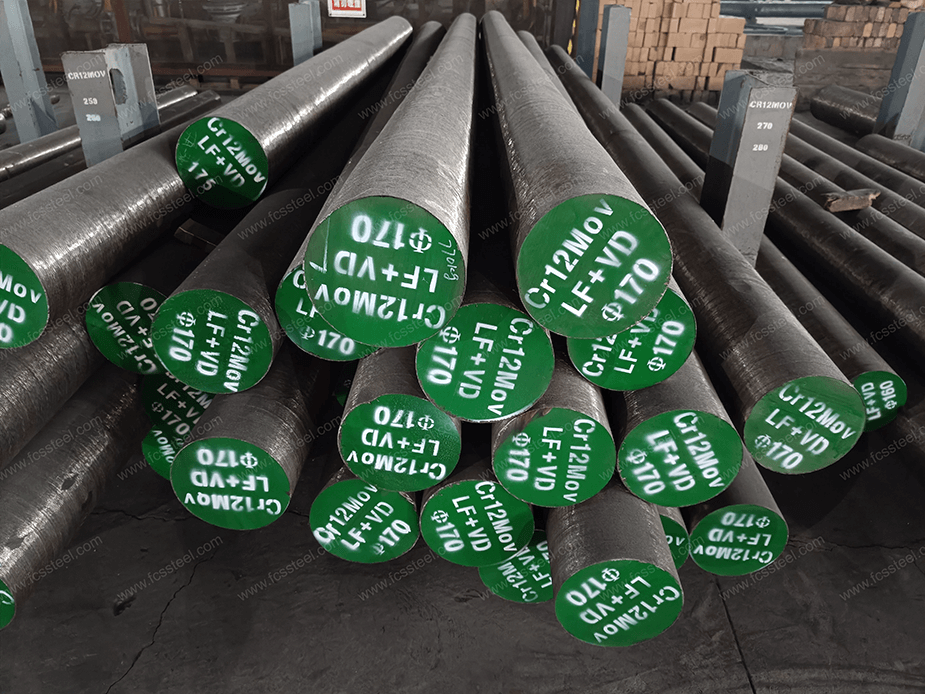

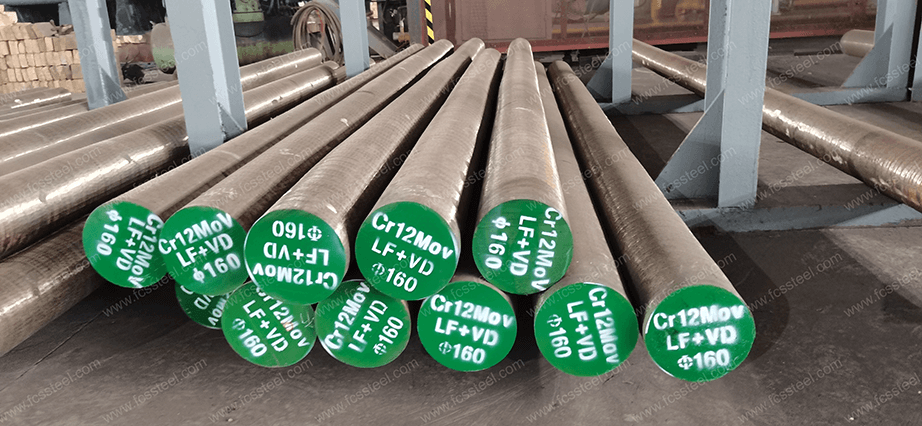

9Cr18 Stainless Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

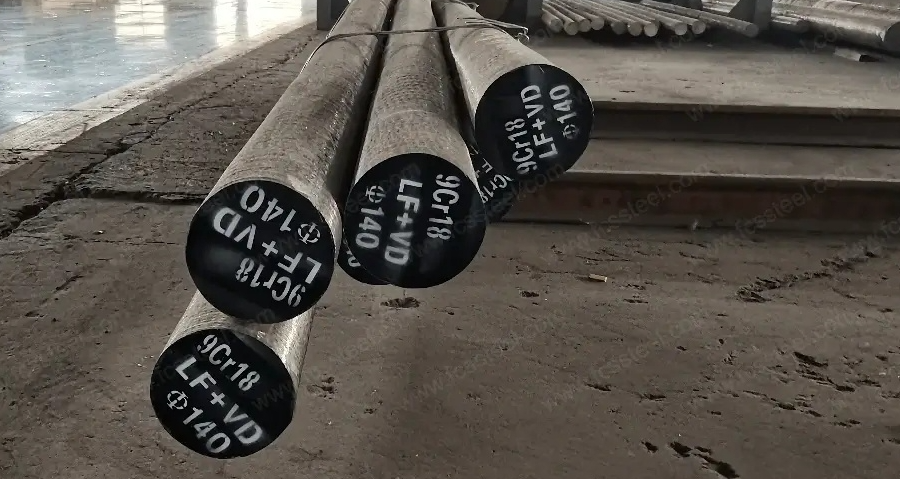

- Round bars

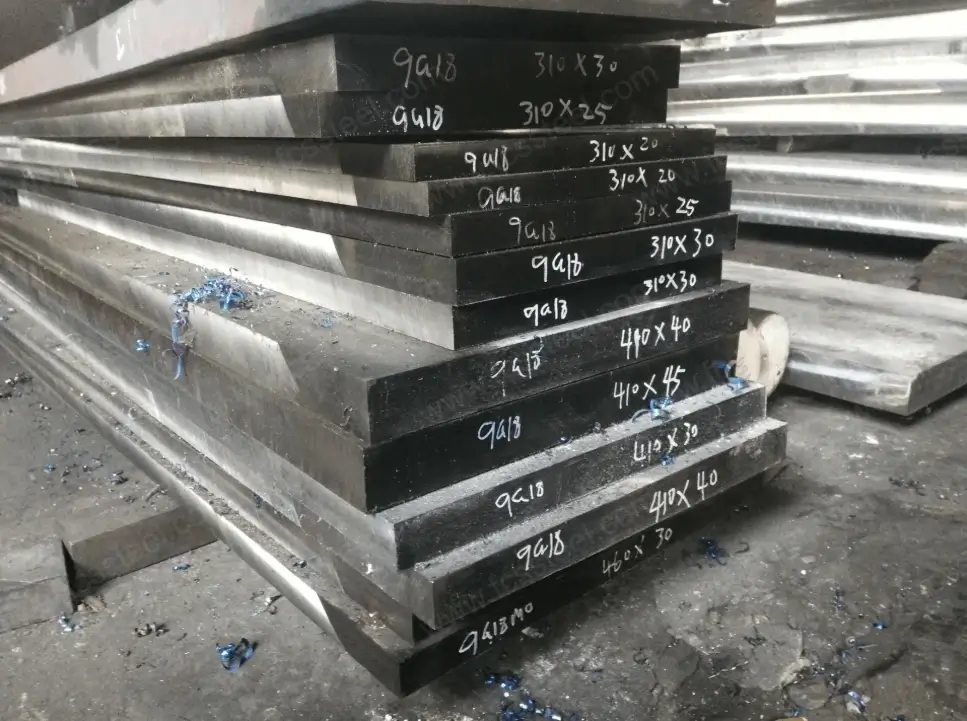

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

9Cr18 Stainless Steel – Forming Methods

- Hot Rolled

- Hot Forged

9Cr18 Stainless Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

9Cr18 Stainless Steel:Material Introduction

9Cr18 is a high-carbon and high-chromium martensitic stainless steel. After appropriate heat treatment, it can achieve high hardness and good wear resistance and corrosion resistance. It is often used in cutting tools, bearing parts, wear-resistant valve parts and mold components with high surface requirements.

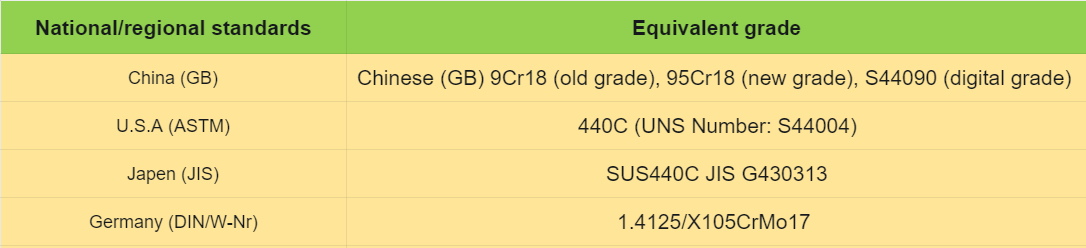

What are the international equivalent grades of 9Cr18 Stainless Steel?

Chemical Composition of 9Cr18 Stainless Steel

9Cr18 Stainless Steel:Material properties

- High hardness potential: After quenching and multiple tempering treatments, 9Cr18 can achieve high quenched hardness and excellent wear resistance.

- Corrosion resistance: With a high chromium content, it has good corrosion resistance in most atmospheres and neutral media (but its corrosion resistance is limited in strong chloride environments).

- Machinability and polishing: The annealed state is easy to machine, and after quenching, a good mirror polishing effect can be achieved. It is suitable for parts and molds with requirements for surface finish.

9Cr18 Stainless Steel:Heat treatment suggestions

The following are commonly used heat treatment Windows in engineering. Verification specimens need to be made based on the cross-section of the workpiece, heating method and cooling conditions.

- Annealing (processing state) : Heat to ~780-820 °C → Slow cooling (furnace cooling or furnace cooling) to room temperature to soften and facilitate mechanical processing.

- Quenching (hardening) : Heat to 1020-1060 °C (austenitizing) → oil cooling or air cooling (depending on part type and equipment).

- Tempering: Low-temperature tempering (200-250 °C) can maintain high hardness. If it is required to increase toughness or reduce tempering brittleness, tempering can be adjusted within the range of 250-350 °C to the target hardness - all of which need to be confirmed by batch tests.

9Cr18 Stainless Steel:Typical application scenarios

- Knives (hand knives, folding knives, kitchen knives) and daily-use tools.

- Precision bearings, ball bearing parts and sliding components.

- Cores and inserts in plastic molding molds that are required to be wear-resistant and have certain corrosion resistance.

- Chemical engineering and pump valve parts (in non-strong chlorination environments).

9Cr18 Stainless Steel:Physical and mechanical reference indicators (Typical values after heat treatment)

The actual values are affected by heat treatment and size. The following are common reference intervals:

- Tensile strength Rm: approximately 700-1200 MPa (related to the hardening grade)

- The impact energy (KV) and elongation after fracture vary significantly with the tempering/cooling rate, and samples should be taken for testing according to the working conditions.

- Hardness range (quenched + tempered) : Can reach HRC 55-62 (depending on the process).

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |

-1.webp)

.png)