95Cr18 | 9Cr18Mo Stainless Steel

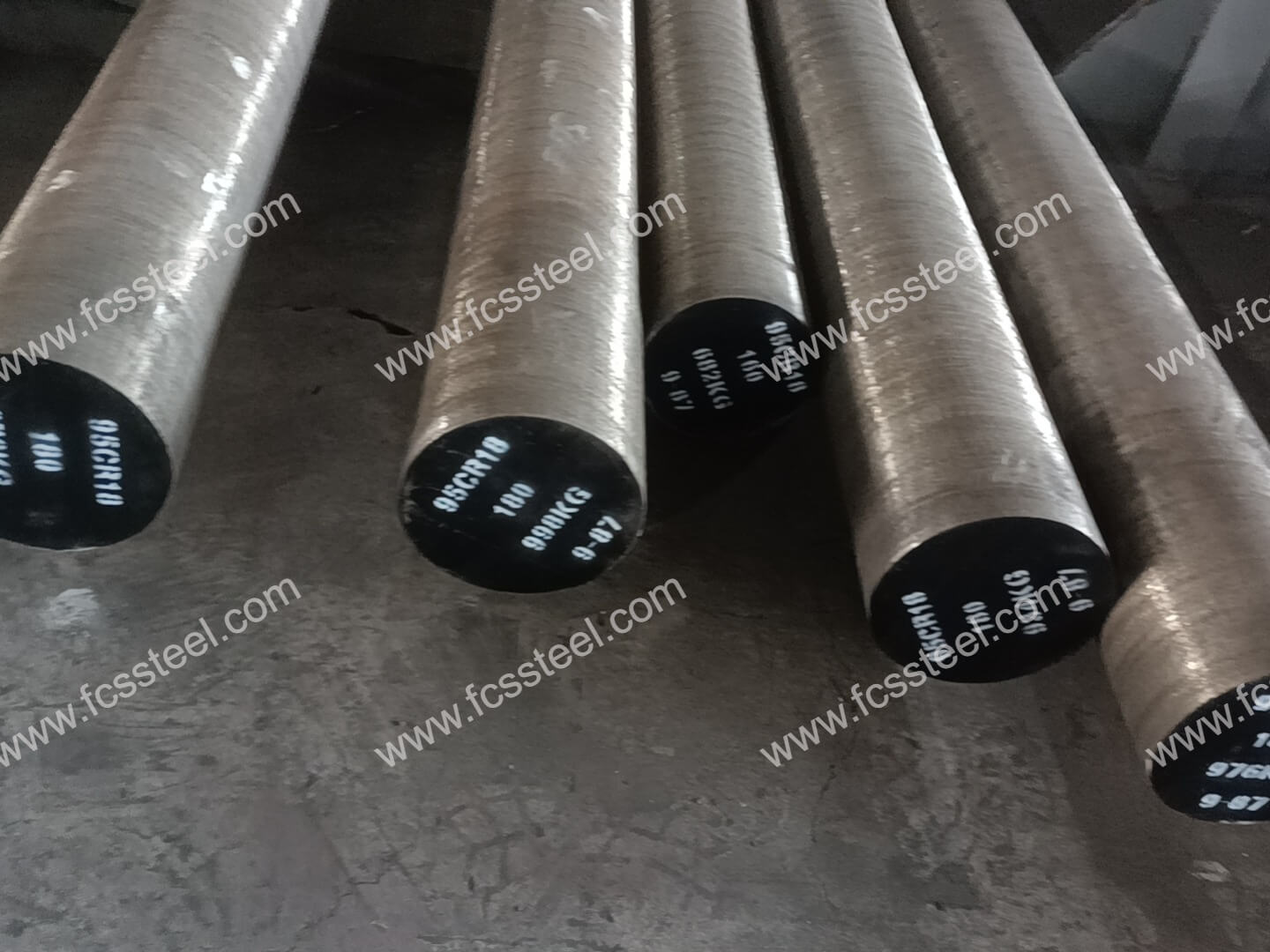

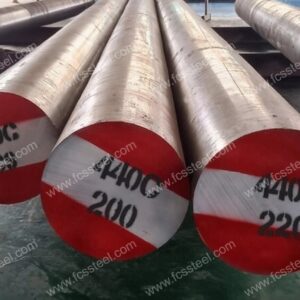

95Cr18 Stainless Steel Types and Options

The table below shows the size range, surface condition and tolerance details for 95Cr18 Stainless Steel:

95Cr18 Stainless Steel Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

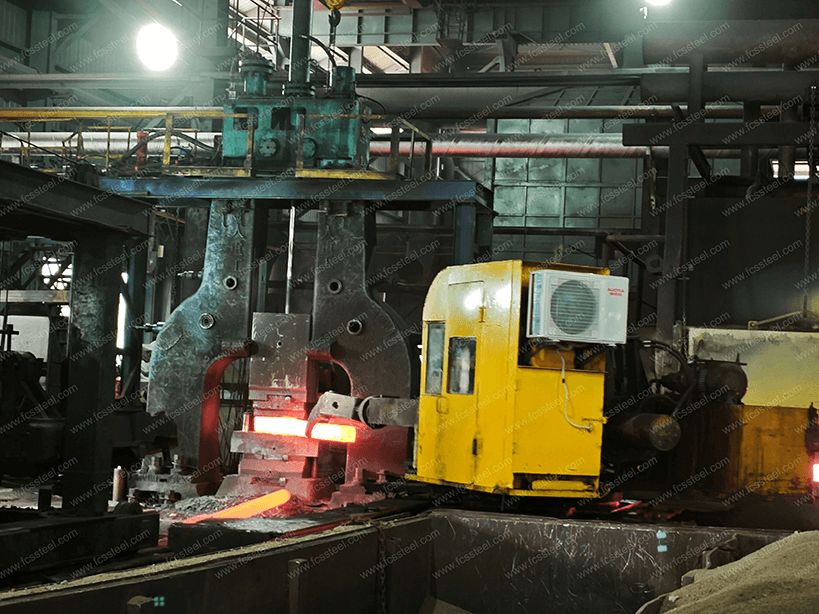

- 95Cr18 Stainless Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

95Cr18 Stainless Steel Chemical Composition

95Cr18 Stainless Steel Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

95Cr18 Stainless Steel Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

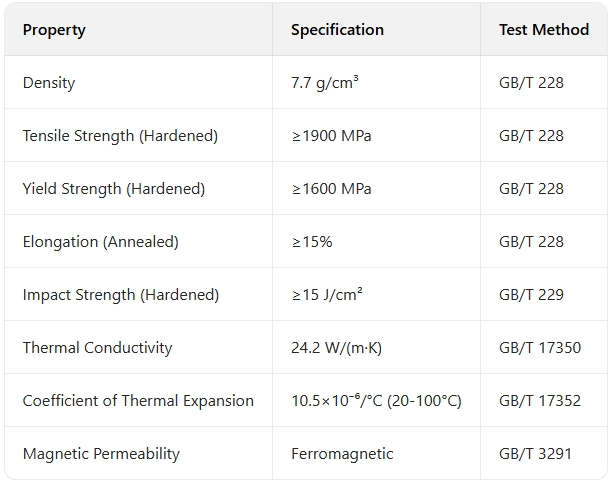

95Cr18 Stainless Steel Technical Specifications

95Cr18 Stainless Steel Product Applications

Precision Cutlery Manufacturing

Our 95Cr18 stainless steel has become the material of choice for high-end knife manufacturers who require superior edge retention and good corrosion resistance. The material is capable of achieving a hardness of 58-60 HRC while maintaining sufficient toughness to give knives an edge life up to three times longer than conventional stainless steel knives. Manufacturers appreciate the material's excellent grindability and polishability, which creates a razor-sharp edge with a mirror finish. A leading kitchen knife manufacturer reported a 40% reduction in customer returns due to dulling issues after switching to our 95Cr18 steel.

High-performance bearing applications

In seawater and corrosive environments, where standard bearing steels can quickly deteriorate, 95Cr18 offers an ideal solution. Its combination of high hardness and corrosion resistance extends bearing life by 300% in salt water exposure applications. The consistent quality of our steel and tight tolerance controls ensure uniform hardness within the component, preventing premature failure. Offshore equipment manufacturers have documented a reduction in maintenance costs of more than 25% with bearings made from our 95Cr18 material.

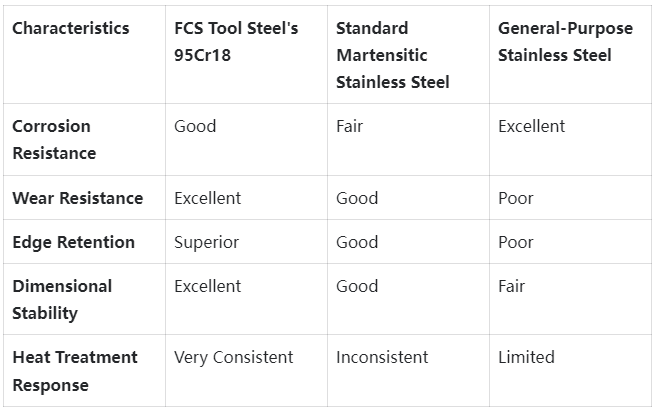

95Cr18 Stainless Steel Competitive Advantage Comparison

95Cr18 Stainless Steel Customer Success Stories

95Cr18 Stainless Steel Pricing Structure Information

95Cr18 Stainless Steel Frequently Asked Questions

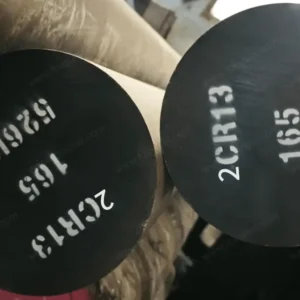

Q1: How does 95Cr18 compare to Western 440C stainless steel?

A1: 95Cr18 is the Chinese standard equivalent of 440C stainless steel with very similar chemical composition and performance characteristics. The main difference is in the standardization and testing protocols, where our material conforms to GB/T standards rather than ASTM or EN standards. In practical applications, properly processed 95Cr18 can provide properties that are indistinguishable from those of premium 440C materials.

Q2: What is the maximum hardness 95Cr18 can achieve?

A2: With proper heat treatment, 95Cr18 can always achieve a hardness of 58-60 HRC. This requires precisely controlled temperatures during austenitization (1030-1050°C), oil quenching, and controlled tempering at 150-180°C. Higher hardness values prioritize wear resistance, while slightly lower temperatures (tempered to 54-56 HRC at 200-250°C) provide better toughness for applications requiring impact resistance.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |