86CrMoV7 Tool Steel

86CrMoV7 is a high-performance hot work die steel, widely used in forging, die casting and extrusion fields. Its alloying elements endow the material with excellent thermal strength, wear resistance and toughness, making it particularly suitable for molds and punches that are subjected to high thermal stress. This steel grade is renowned for its balanced performance in hardenability, thermal fatigue resistance and long service life.

Product Forms Available

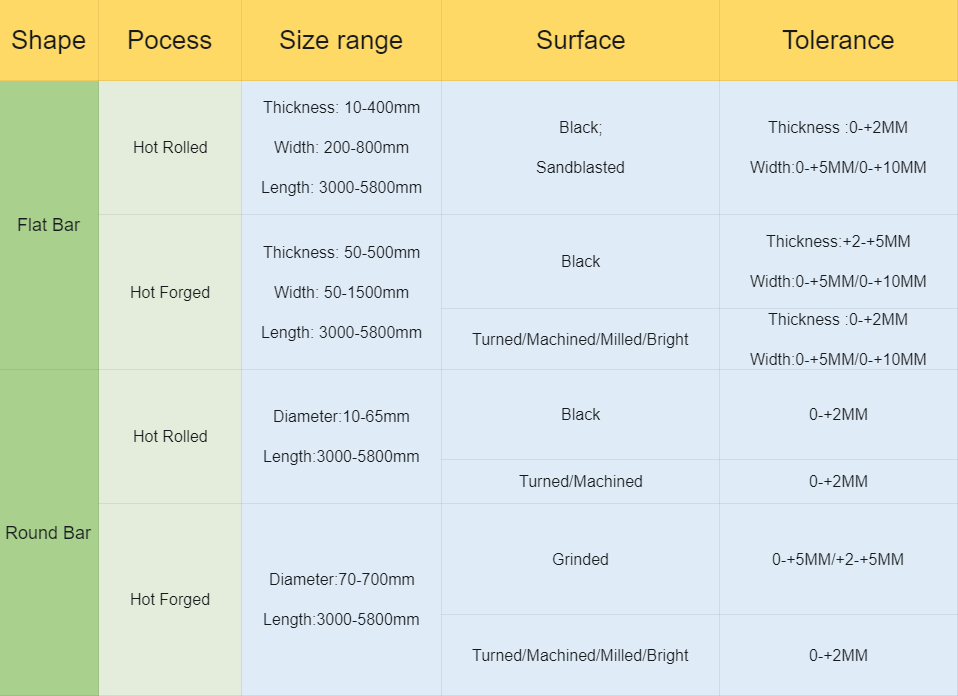

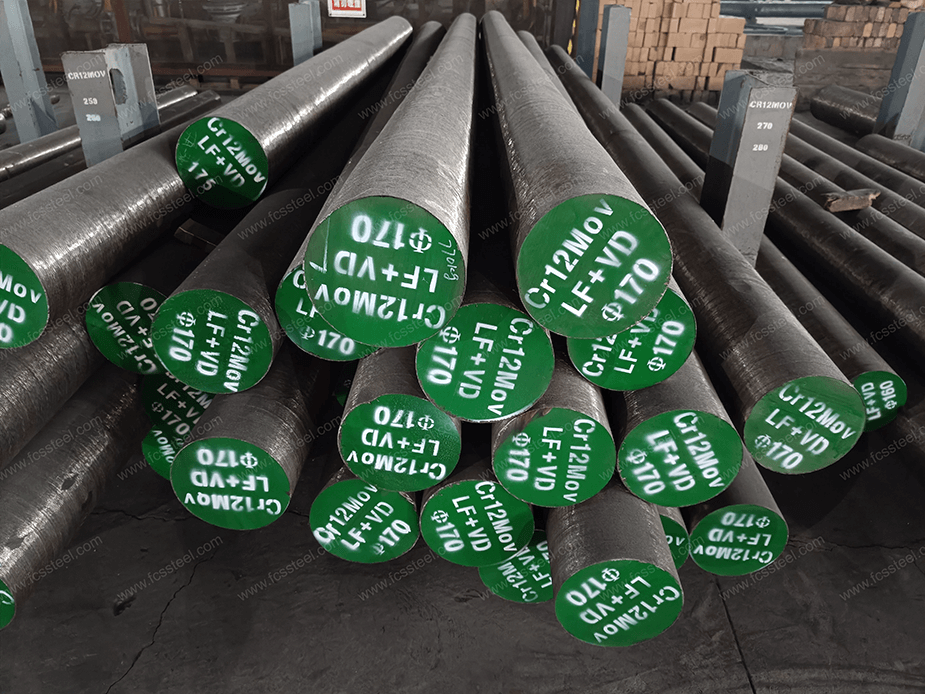

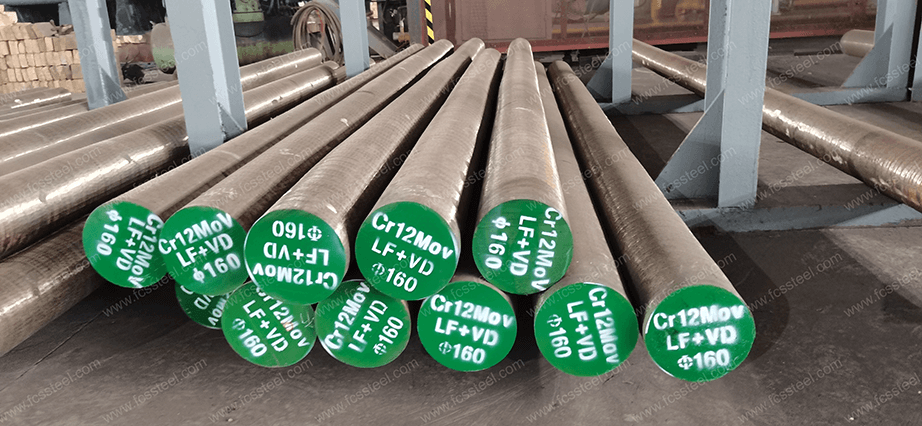

FCS Tool Steel supplies 86CrMoV7 in multiple shapes to meet diverse manufacturing needs:

- Hot Rolled Bars & Hot Forged Bars

- Round steel & Plates/Flat in Stock

- Round Bars (10mm –700mm diameter),Plate/Flat (Thickness: 8 – 45 mm / 50 – 500 mm,Width: 50 – 1000 mm / 50 – 1500 mm.)

- Custom-cut pieces

Overview of 86CrMoV7 Tool Steel

86CrMoV7 tool steel is a high-performance alloy tool steel that complies with German standards (material No. 1.2327). Its chemical composition is based on carbon to ensure hardness and wear resistance, combined with chromium to enhance hardenability and corrosion resistance, and supplemented by molybdenum and vanadium to refine grains, enhance resistance to tempering softening and toughness. At the same time, control the content of phosphorus and sulfur to reduce brittleness and improve processability. It can adapt to the working conditions with long-term high wear and high stress.

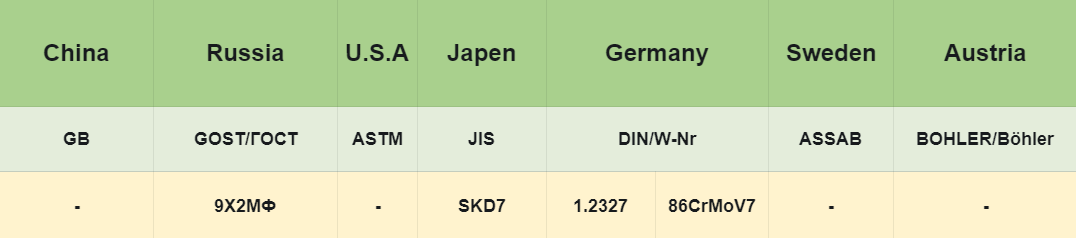

International Equivalent Grades of 86CrMoV7 Tool Steel

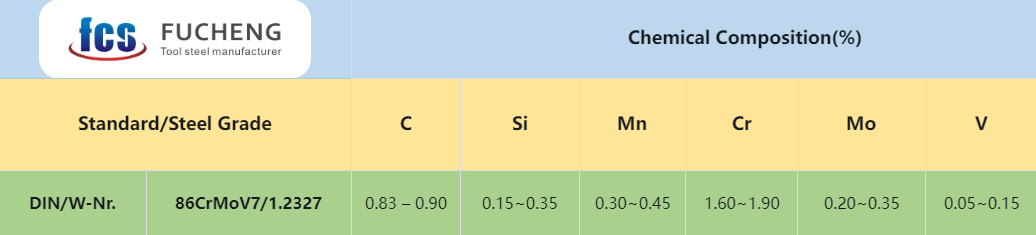

86CrMoV7 Tool Steel:Chemical Composition

- Carbon (C): 0.83 – 0.90

- Chromium (Cr): 1.60 – 1.90

- Molybdenum (Mo): 0.25 – 0.35

- Vanadium (V): 0.05 – 0.15

- Manganese (Mn): 0.30 – 0.45

- Silicon (Si): 0.15 – 0.35

This optimized composition ensures stable hardness after heat treatment and excellent resistance to cracking during service.

86CrMoV7 Tool Steel:Product Specification

Mechanical Properties (Heat Treated)

- Hardness (after tempering): 44 – 50 HRC

- Tensile Strength: 1,000 – 1,300 MPa

- Impact Toughness: High due to balanced alloy design

- Thermal Resistance: Performs well at working temperatures up to 600°C

Heat Treatment Process

- Annealing: 750 – 780°C, slow furnace cooling → hardness approx. 220 HB

- Hardening: Preheat to 600°C, austenitize at 1000 – 1030°C, then oil or air quench

- Tempering: 2–3 cycles at 550 – 650°C for optimum toughness and stability

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |

.png)

-1-300x300.png)