8407 Tool Steel

8407 is a high-quality hot work tool steel launched by ASSAB of Sweden, corresponding to AISI H13 or DIN 1.2344 (JIS SKD61) commonly known internationally. It adopts a Cr-Mo-V alloying design, featuring excellent thermal fatigue resistance and temperature strength, as well as good processing performance. It is widely used in mold manufacturing in high-temperature load environments such as casting, extrusion, hot forging, hot stamping, and injection molding.

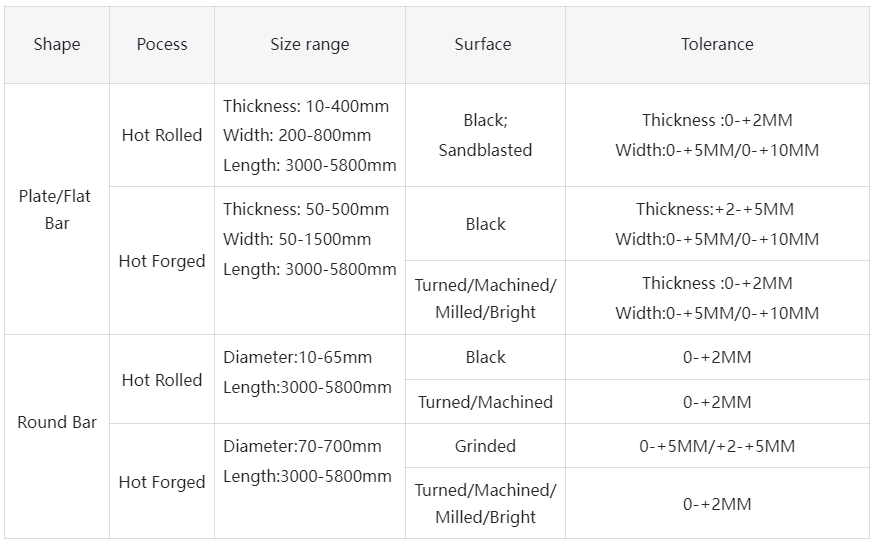

8407 Tool Steel Size Range

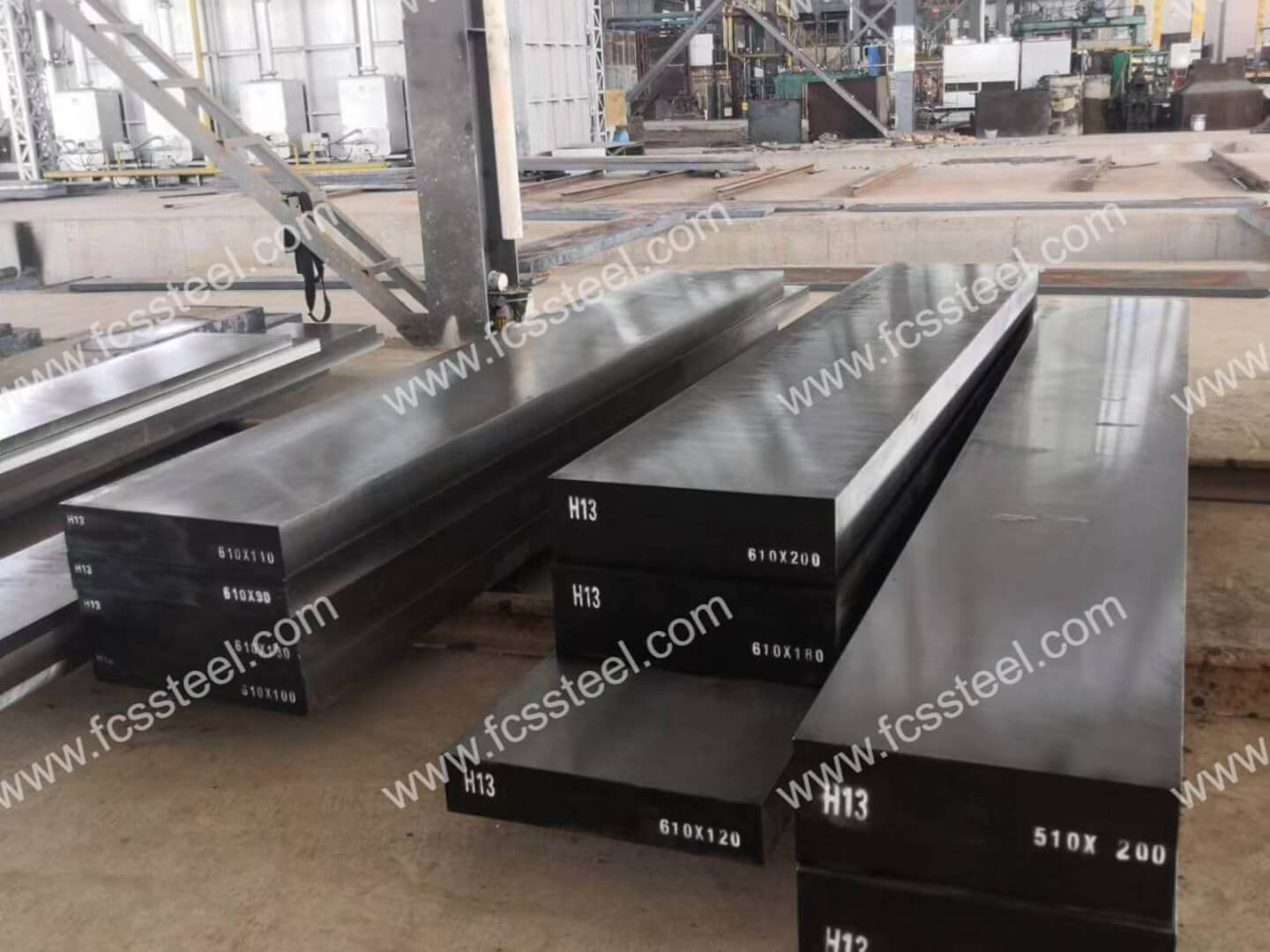

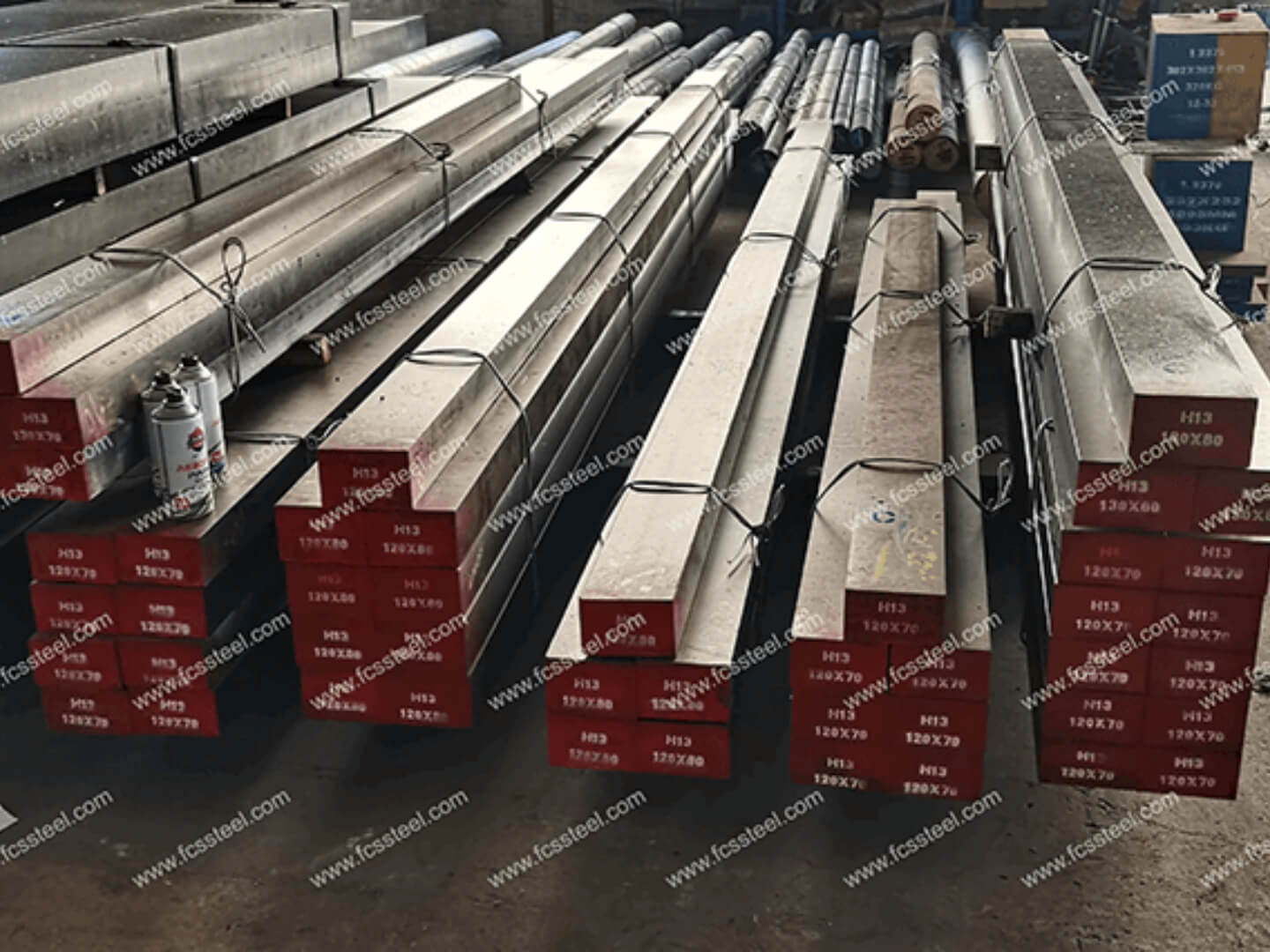

- Hot Rolled Plate/Flat Bar:Thickness: 10-400mm,Width: 200-800mm,Length: 3000-5800mm

- Hot Forged Plate/Flat Bar:Thickness: 50-500mm,Width: 50-1500mm,Length: 3000-5800mm

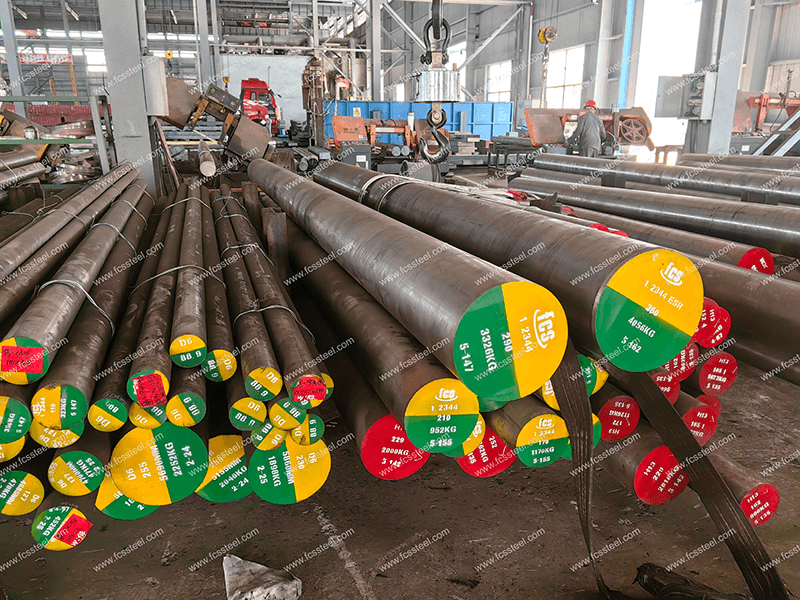

- Hot Rolled Round Bar: Diameter 10-65mm,Length 3000-5800mm

- Hot Forged Round Bar:Diameter:70-700mm,Length:3000-5800mm

8407 Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

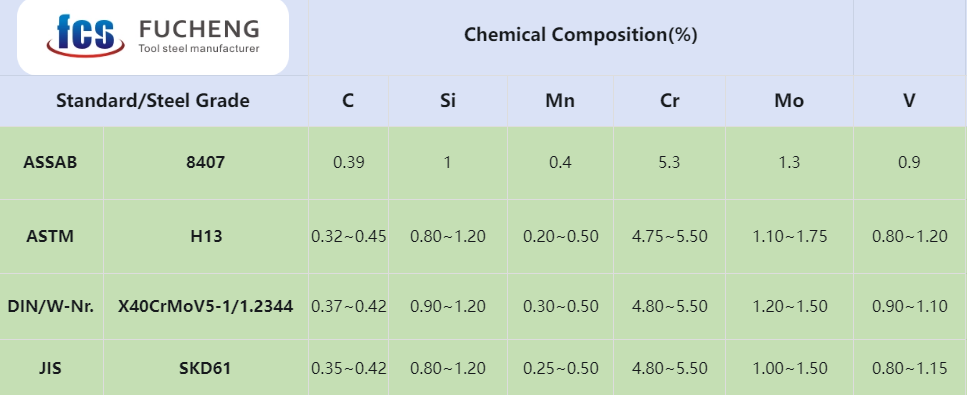

8407 Tool Steel Chemical Composition

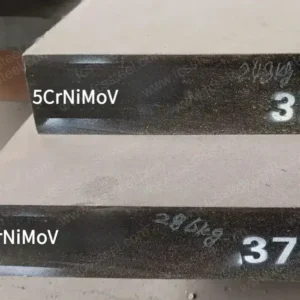

8407 Tool Steel Equivalent Grades

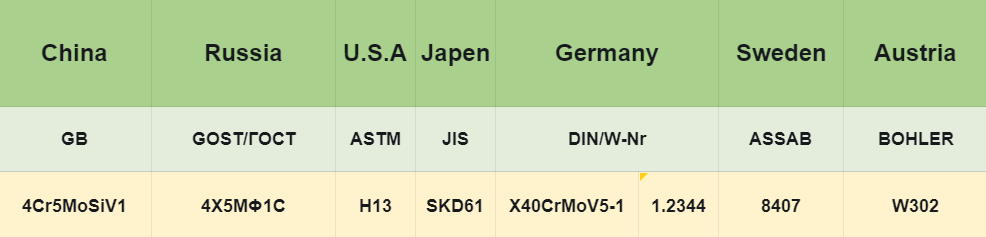

The approximate correspondence of 8407 in the standards of various countries is as follows:

- China (GB):4Cr5MoSiV1

- Germany (DIN / W-Nr):X40CrMoV5-1/1.2344

- Japan (JIS):SKD61

- USA (AISI/ASTM):H13

- Sweden (ASSAB):8407

- Austria (BÖHLER):W302

- Russia(GOST/ГОСТ):4X5MΦ1C

8407 Tool Steel Specifications

8407 Tool Steel Customized Options

- Custom Surface Conditions: Black; Sandblasted; Grinded; Turned/Machined/Milled/Bright

- Custom Chemical Composition: Capable of producing standard grades such as GB, DIN, ASTM, JIS, etc. Chemical composition can be custom-produced individually.

- Custom Specifications: Round steel (diameter) and plates (thickness, width) can be custom-produced.

- Professional packaging for long-term storage or extreme transportation conditions: Including black paint spraying on all sides, plastic film wrapping, anti-rust oil spraying, and delivery in wooden cases.

- Custom production according to samples or technical agreements.

- 8407 Tool Steel Electroslag Remelting (8407 ESR): Premium option with higher purity and isotropic properties for critical applications.

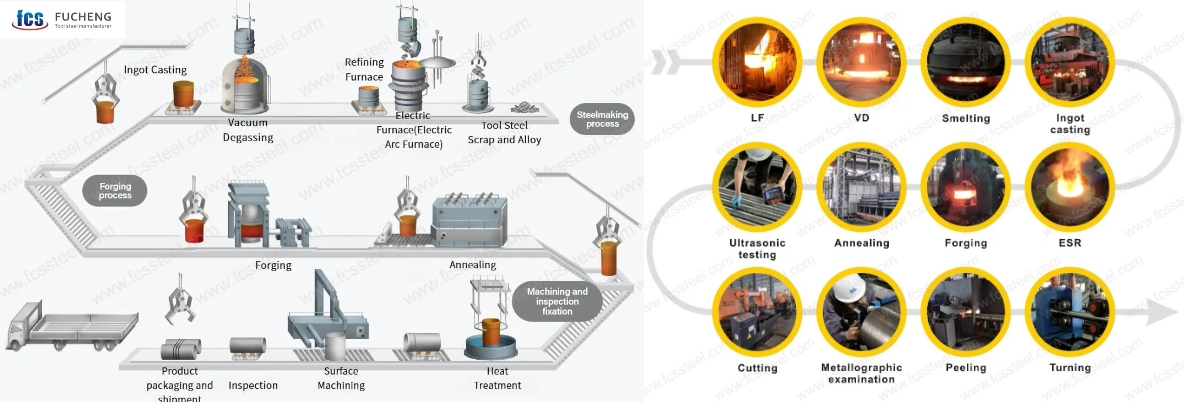

8407 Tool Steel Smelting process

8407 Tool Steel Physical Properties

- Density: approximately 7.8 g/cm³

- Elastic modulus: approximately 210-215 GPa (20 °C)

- Thermal conductivity: approximately 20-25 W/m·K

- Coefficient of thermal expansion: approximately 12×10⁻⁶/K in the range of 20-200 °C

These characteristics make its thermal behavior stable in high-temperature environments, making it highly suitable for mold applications.

8407 Tool Steel Mechanical & Performance Properties

- Thermal fatigue resistance: It has a high resistance to hot cracking and thermal shock.

- High-temperature strength: Maintains strength at 500-600 °C.

- Strong toughness and crack resistance: Excellent damage resistance for guiding and thick cross-section molds.

- Good hardenability: Uniform hardness remains even after heat treatment of large-sized materials.

- Excellent processing and polishing performance: The machine processing efficiency is high, and the surface can achieve a high degree of smoothness.

8407 Tool Steel Product Applications

-

- Die-casting mold

- Hot forging and hot stamping dies

- Extrusion dies, injection molds

- High-speed cutting tools and other tools used in high-temperature thermal load environments.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |