1.2714 | 6F3 | 56NiCrMoV7 Tool Steel

Modern manufacturing is increasingly demanding efficiency and durability in high stress tooling applications. Conventional tool steels often fail prematurely under extreme thermal cycling, high pressure and abrasive wear conditions, resulting in costly downtime and replacement.

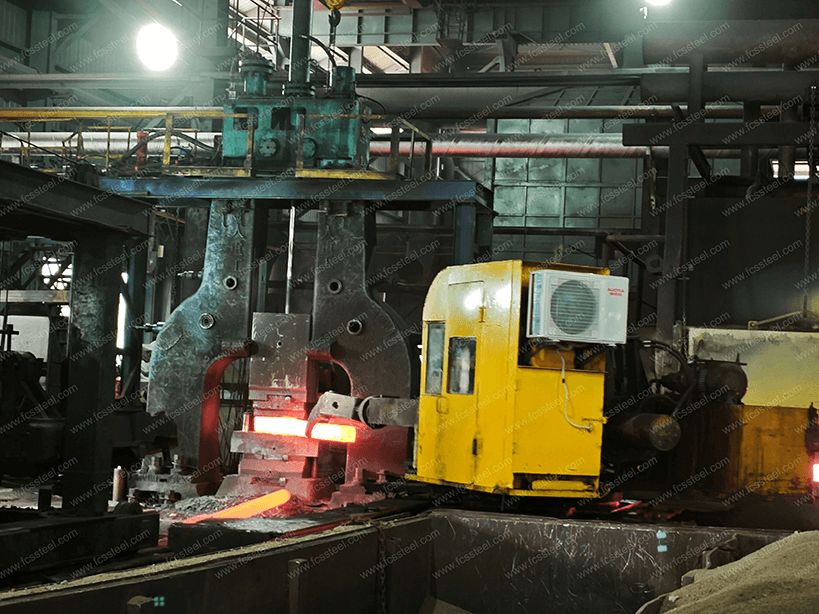

FCS Factory’s range of premium hot work tool steels (6F3, 1.2714, 56NiCrMoV7 ) address these challenges through advanced metallurgical composition design and precise heat treatment processes. These speciality alloys optimise the content of nickel, molybdenum, chromium and vanadium, enhancing thermal stability, wear resistance and toughness through synergistic action.

As a result, manufacturers experience significantly longer tool life, reduced maintenance intervals, and improved part quality.FCS TOOL STEEL customers typically report 30-45% longer service intervals for tooling applications, improved dimensional accuracy, and a direct increase in productivity and reduction in total cost of ownership.

1.2714 | 6F3 | 56NiCrMoV7 Tool Steel Product Introduction

6F3 tool steel (American Standard ASTM)

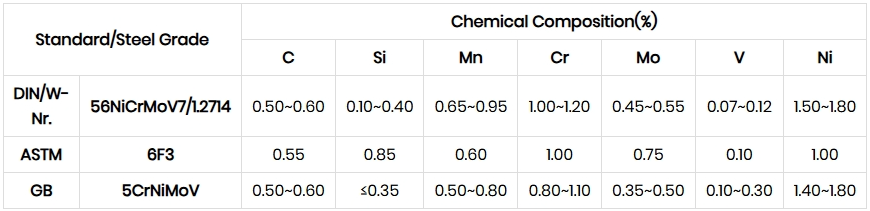

6F3 tool steel is a hot work mould steel, the implementation of the standard GB/T 1299-2014. Its chemical composition mainly includes 0.55% carbon, 0.85% silicon, 0.60% manganese, 1.00% chromium, 0.75% molybdenum, 0.10% vanadium. The steel has been refined by electroslag remelting (ESR) to provide high purity, homogeneous organisation and excellent toughness and thermal fatigue resistance. It has a hardness of 58-60 HRC in the quenched and tempered condition and a low coefficient of thermal expansion (approx. 11.2 x 10-⁶/°C, 20-600°C), which reduces distortion caused by thermal stresses.

1.2714 Tool Steel (German Standard W-Nr/DIN)

Composition and Physical Properties: 1.2714 tool steel (German Standard, equivalent to 56NiCrMoV7) is a nickel-chromium-molybdenum-vanadium alloyed hot-work tool steel, with a composition of carbon (0.50%-0.60%), nickel (1.50%-1.80%), chromium (1.00%-1.30%), nickel (1.50%-1.80%) and chromium (1.00%-1.30%). 1.00%-1.20%), molybdenum (0.45%-0.55%) and vanadium (0.07%-0.12%).

Heat treatment and properties: hardness 48-52 HRC after oil or gas quenching (830-900°C) and tempering (200-650°C), with high toughness (impact value ≥ 25 J) and thermal fatigue resistance. Requires controlled tempering temperature gradients to balance hardness and residual stresses, and is sensitive to metallurgical purity (white point defects need to be limited).

56NiCrMoV7 tool steel (DIN, equivalent to 1.2714)

Consistency of composition and properties: 56NiCrMoV7 and 1.2714 are different designations for the same material, with identical compositions (Carbon 0.50%-0.60%, Nickel 1.50%-1.80%, Chromium 1.00%-1.30%, Molybdenum 1.00%-1.30%, and Carbon 1.00%-1.30%). -1.20%, molybdenum 0.45%-0.55%, vanadium 0.07%-0.12%). High-temperature strength is outstanding (500°C hardness maintains HB 300), but toughness is significantly affected by microstructure uniformity.

Process characteristics: wide quenching temperature window (oil/air quenching at 880-900°C), hardness gradient decreases with increasing temperature after tempering (approx. 54 HRC at 200°C, approx. 40 HRC at 600°C). They require electroslag remelting (ESR) to improve purity and have a low heat treatment distortion rate, making them suitable for precision machining.

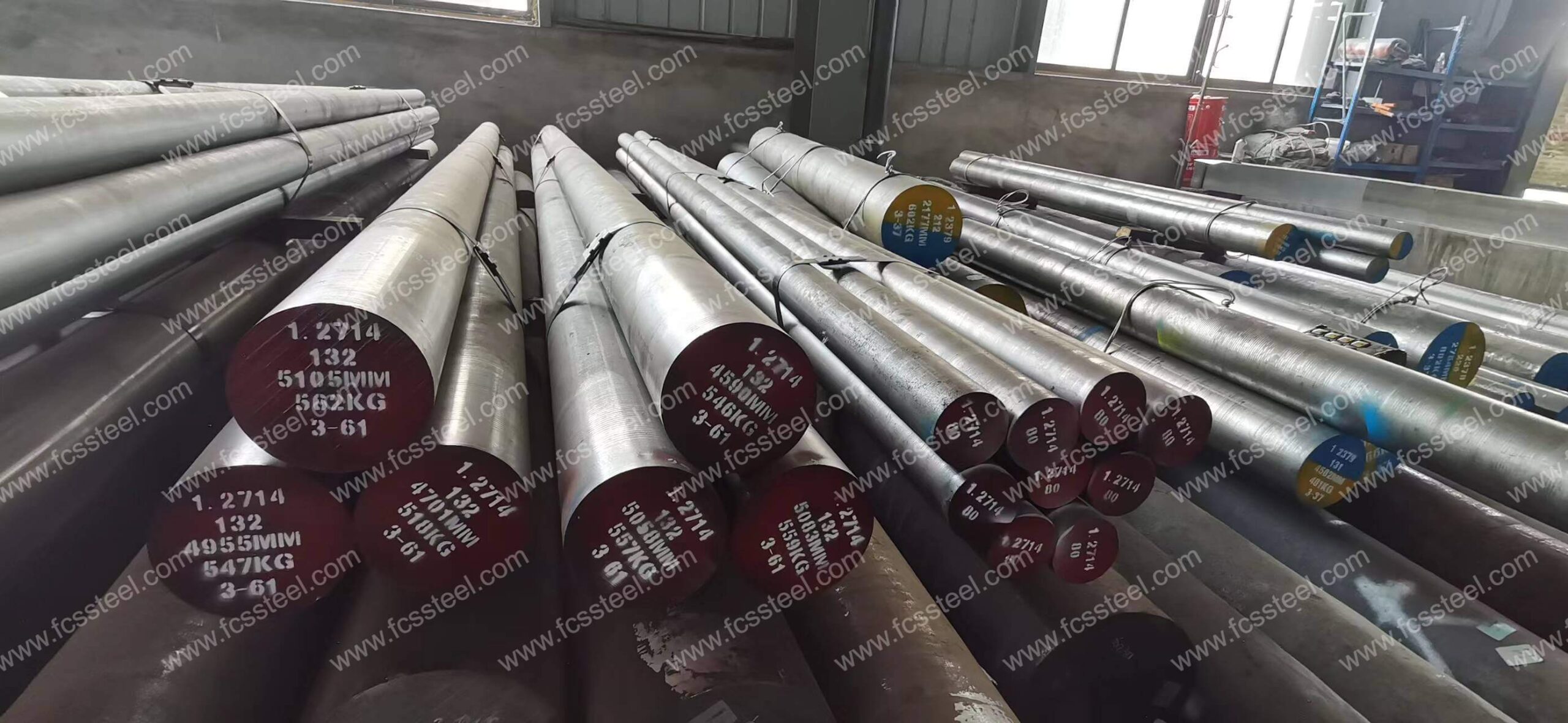

1.2714 | 6F3 | 56NiCrMoV7 Tool Steel Types and Options

The table below shows the size range, surface condition and tolerance details for 6F3/1.2714/56NiCrMoV7 Tool Steel:

1.2714 | 6F3 | 56NiCrMoV7 Tool Steel Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- 6F3/1.2714/56NiCrMoV7 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

1.2714 | 6F3 | 56NiCrMoV7 Tool Steel Chemical Composition

1.2714 | 6F3 | 56NiCrMoV7 Tool Steel Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

1.2714 | 6F3 | 56NiCrMoV7 Tool Steel Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

1.2714 | 6F3 | 56NiCrMoV7 Tool Steel Technical Specifications

1.2714 | 6F3 | 56NiCrMoV7 Tool Steel Product Applications

FORGING DIE APPLICATIONS

Our range of hot work die steels excels in heavy duty forging die applications subject to extreme thermal and mechanical stresses. In particular, the optimised composition of grade 1.2714 tool steel provides excellent resistance to hot cracking and thermal fatigue. A German automotive component manufacturer has improved crankshaft forging die life by 42% after using our tool steel. Its superior toughness prevents premature cracking while maintaining excellent wear resistance (even when machining difficult-to-forge superalloys). The tool maintains dimensional accuracy over thousands of heating/cooling cycles, ensuring consistent part quality and reducing costly tool replacement and maintenance.

Hot Stamping and Press Hardening Tools

The growing demand for high strength steel components in the automotive sector requires work materials with excellent high temperature hardness, wear resistance and thermal conductivity. Our 56NiMoCrV7 grade offers the ideal combination of properties for hot stamping operations due to its increased vanadium content. Uniform heat distribution reduces cycle times, while high-temperature strength prevents premature deformation of the work surface. When a high-end automotive manufacturer used our tool steel in a hot stamping line for B-pillar components, production speeds increased by 38 per cent and tool maintenance was reduced by 45 per cent. Excellent surface quality retention ensures consistent part appearance while reducing friction and material adhesion problems.

Extrusion Dies and Tooling

Aluminium and copper extrusion operations expose tooling to high temperatures and abrasive wear. Our 6F3 tool steel grade excels in these demanding applications with an optimal balance of thermal hardness and toughness. Excellent thermal conductivity ensures uniform temperature distribution and dimensional stability over long operating times. An Italian aluminium profile manufacturer has increased repair intervals by 35% after applying our tool steel to complex profile dies. The excellent polishability of our material ensures an outstanding surface finish of the extruded product, while reducing friction and die sticking, increasing extrusion speed and energy efficiency.

Hot shear applications

Hot cutting operations of billets, bars and forgings create extremely demanding conditions for tooling materials. Our premium hot work die steel grades, particularly vanadium-enhanced 56NiMoCrV7 tool steel, provide excellent edge retention and wear resistance in these applications. Excellent high temperature mechanical properties prevent premature edge deformation, while optimised toughness prevents chipping and catastrophic failure. A Central European steel mill used our tool steel for hot shear blades and increased edge life by 50 per cent when cutting 1100°C billets, dramatically reducing downtime for blade changes and improving productivity.

Plastic forming applications

In addition to traditional hot metal forming, our tool steel range excels in high-performance plastic forming applications. 1.2714 grade's excellent thermal conductivity ensures fast and even heat distribution, consistent cycle times and part quality. Excellent wear resistance copes with abrasive fillers in engineering plastics while maintaining dimensional accuracy and surface finish. When a medical device manufacturer used our tool steel in injection moulds for glass fibre-reinforced polyamide parts, it saw a 40% increase in production cycles between maintenance intervals, as well as improved part consistency and reduced scrap.

Die casting moulds

Aluminium, zinc and magnesium die casting operations subject tooling to thermal fatigue, erosion and fusion problems. Our hot work mould steel grades offer excellent resistance to thermal cracking and their thermal properties optimise cooling rates and cycle times. Excellent surface quality retention prevents premature erosion and washout in high-speed areas of the mould. After an automotive parts die casting plant applied our tool steel to a complex gearbox housing mould, mould maintenance costs were reduced by 33% and productivity increased by 25% due to longer service intervals and less downtime.

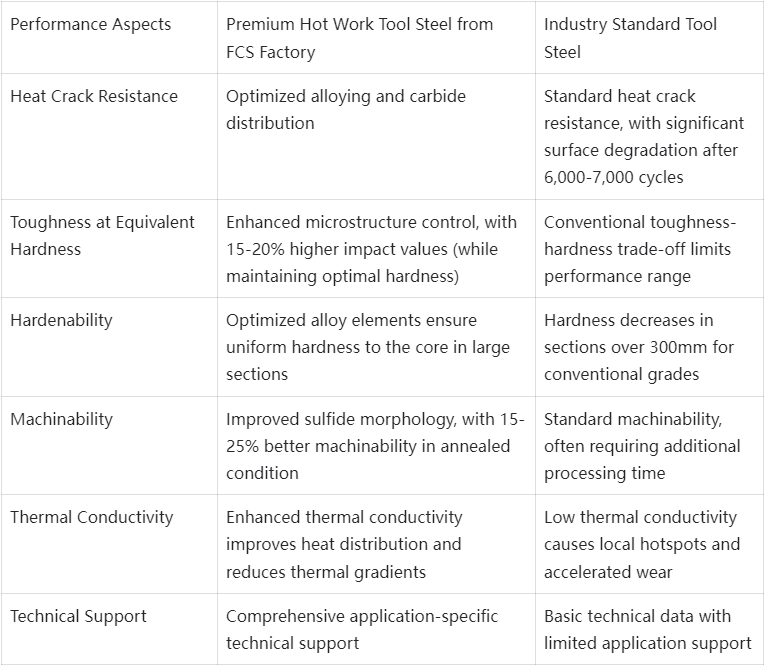

1.2714 | 6F3 | 56NiCrMoV7 Tool Steel Competitive Advantage Comparison

1.2714 | 6F3 | 56NiCrMoV7 Tool Steel Customer Success Stories

1.2714 | 6F3 | 56NiCrMoV7 Tool Steel Pricing Structure Information

1.2714 | 6F3 | 56NiCrMoV7 Tool Steel Frequently Asked Questions

Q: How do I determine which grade is best for my particular application?

A: The optimum grade depends on a number of factors, including operating temperature, cycle time, applied stress and desired tool life. In general, 6F3 excels in applications where maximum toughness is required, 1.2714 provides an excellent balance of properties in most forging applications, and 56NiCrMoV7 provides enhanced wear resistance in applications where surface degradation is a major concern. Our technical team can provide detailed advice based on the specific requirements you provide.Q: What are the key considerations when processing these premium tool steels?

A: Whilst our grades offer better machinability than many tool steels, we recommend the use of carbide tools with appropriate geometry for optimum efficiency. Annealed hardnesses are typically ≤241 HBS, allowing for conventional machining methods (subject to adjustment of cutting parameters). Our detailed machining guides provide specific advice on a variety of operations, including milling, turning, grinding and EDM.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |