6CrW2Si Tool Steel

6CrW2Si tool steel, based on chromium-silicon steel, rationally adds tungsten elements to enhance quenching hardness and red hardness, while improving impact toughness. It is suitable for applications where high wear and brittle impact coexist.

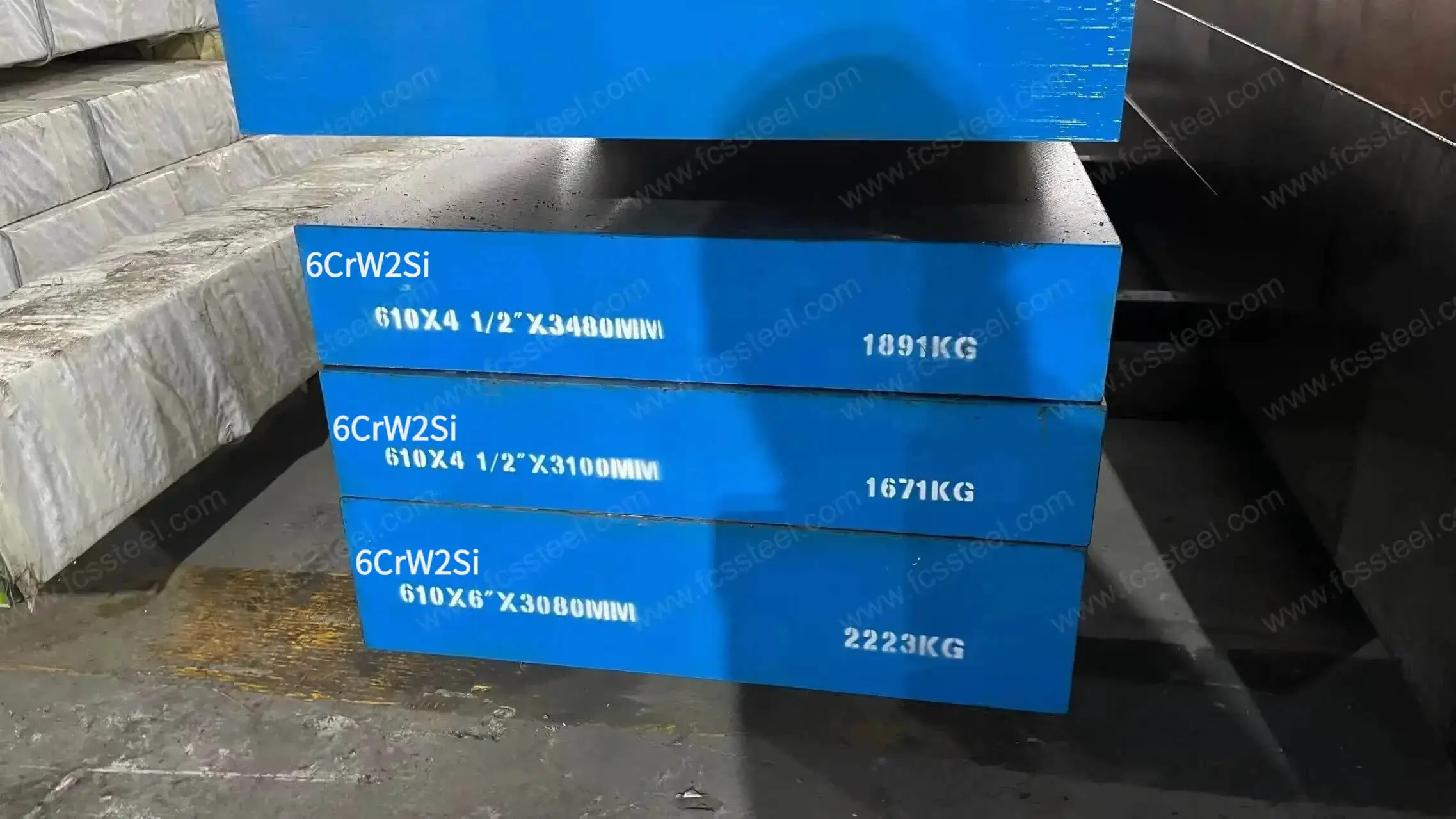

6CrW2Si Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

6CrW2Si Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

6CrW2Si Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

What is 6CrW2Si Tool Steel?

6CrW2Si is a type of cold work tool steel under the Chinese standard GB/T 1299-2000/1299-2014.

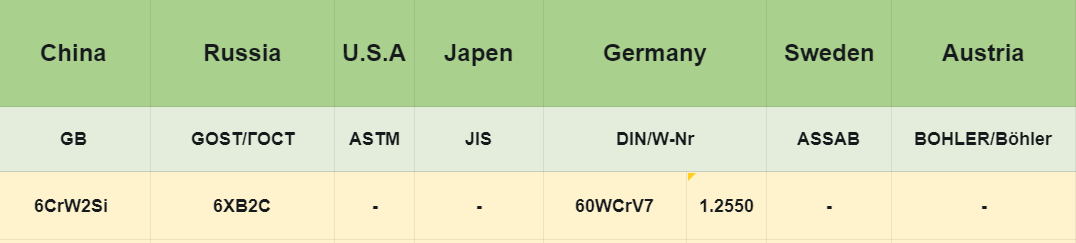

International Equivalent Grades of 6CrW2Si Tool Steel

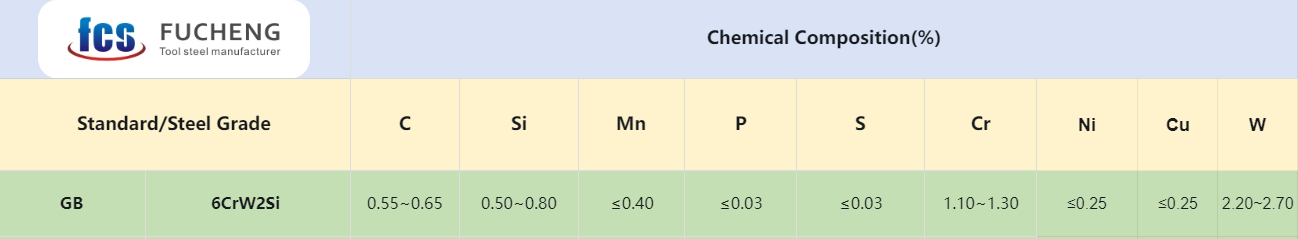

Chemical Composition of 6CrW2Si Tool Steel

6CrW2Si Steel Product Specifications

6CrW2Si Steel Heat Treatment Processes and Properties

- Annealing: Hold at 800–820 °C for 3–5 hours, furnace cool to ≤550 °C and then air cool. Hardness is approximately 230–285 HBW (229–285 HB).

- Quenching: Oil cool at 860–900 °C. Hardness is ≥57 HRC, with a maximum of 60–65 HRC (according to cutting reports).

- Tempering: Tempering at 200–250 °C is used for performance stabilization (approximately 53–58 HRC); tempering at 400–450 °C can improve toughness (approximately 45–52 HRC); attention should be paid to avoiding the brittleness peak in the 300–350 °C range.

Notes: Carbide segregation may occur in large cross-sections, requiring strict temperature control and uniform cooling.

6CrW2Si Steel Recommended Typical uses

6CrW2Si is particularly suitable for manufacturing tools and molds that are subject to high impact resistance and require high wear resistance.

- Cold shears, blanking and trimming dies

- Heavy-duty punches and punching equipment

- Pneumatic impact operation tools (such as punching caps, air hammer accessories)

- Hot riveting punches, die-cast parts, impact wear-resistant parts

- Steel structure striking tools, impact measuring tools and industrial peeling tools

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |