5CrNiMo Tool Steel

5CrNiMo is an alloy die steel (Chinese GB series) optimized for hot working/thermal shock conditions. By adding chromium, nickel and molybdenum to the medium carbon matrix, it achieves high strength, high thermal fatigue strength and good toughness. It is often used in molds and tools that need to withstand impact or friction at high temperatures and is a common domestic option in the field of hot working molds.

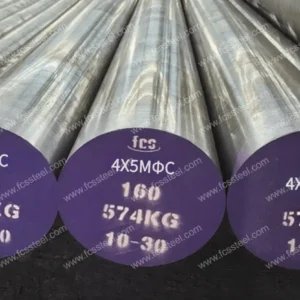

5CrNiMo Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

5CrNiMo Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

5CrNiMo Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

What is 5CrNiMo Tool Steel?

5CrNiMo Tool Steel plays an irreplaceable and important role in the field of industrial manufacturing with its outstanding chemical composition design, excellent physical properties, diverse supply forms, wide application fields, scientific heat treatment process and prominent material advantages. It is an ideal choice for numerous manufacturing enterprises to enhance product quality, increase production efficiency and reduce production costs.

International Equivalent Grades of 5CrNiMo Tool Steel

Chemical Composition of 5CrNiMo Tool Steel

5CrNiMo Steel Product Specifications

5CrNiMo Steel:Typical mechanical/performance indicators

With variations depending on the factory/grade:

- Tensile strength: approximately 650-900 MPa (related to heat treatment).

- Impact energy: ≥ 78 J (The index may vary after annealing/quenching and tempering).

- Hardness (annealed) : ≤ ~280 HB; After quenching and tempering, it can reach the specified HRC level as required.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |