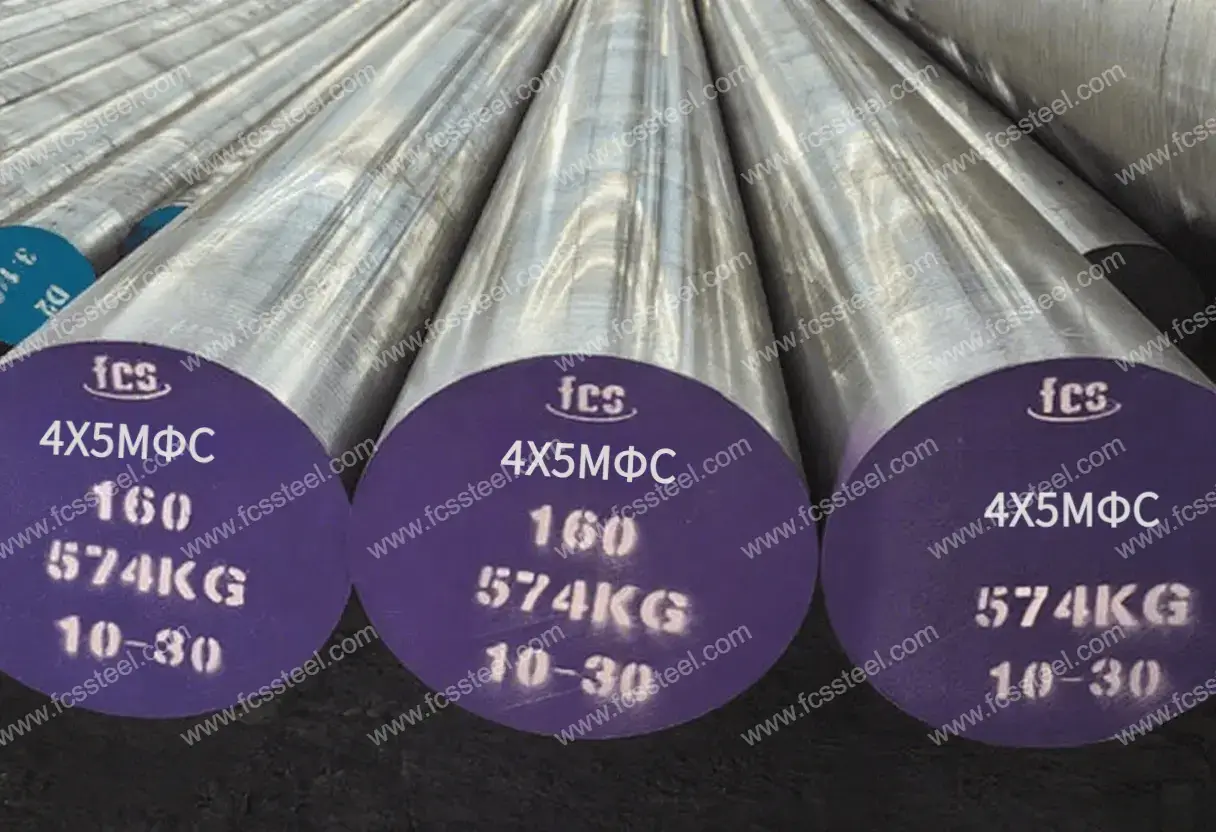

4X5MΦC Tool Steel

4X5MΦC is a medium-alloyed hot work tool steel, belonging to the chromium-molybdenum-vanadium type of tool steel, with excellent red-hardness, heat-fatigue-resistant properties and good resistance to thermal cracking, widely used in the manufacture of moulds and tools working at high temperatures and under hot load conditions.

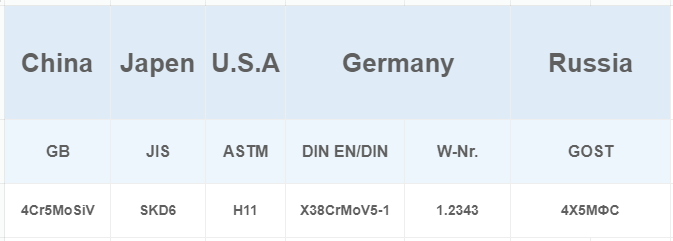

The corresponding American ASTM grade for 4X5MΦC is H11, the Japanese JIS grade is SKD6, the German DIN/W-Nr grade is X38CrMoV5-1/1.2343, and the Chinese standard GB grade is 4Cr5MoSiV.

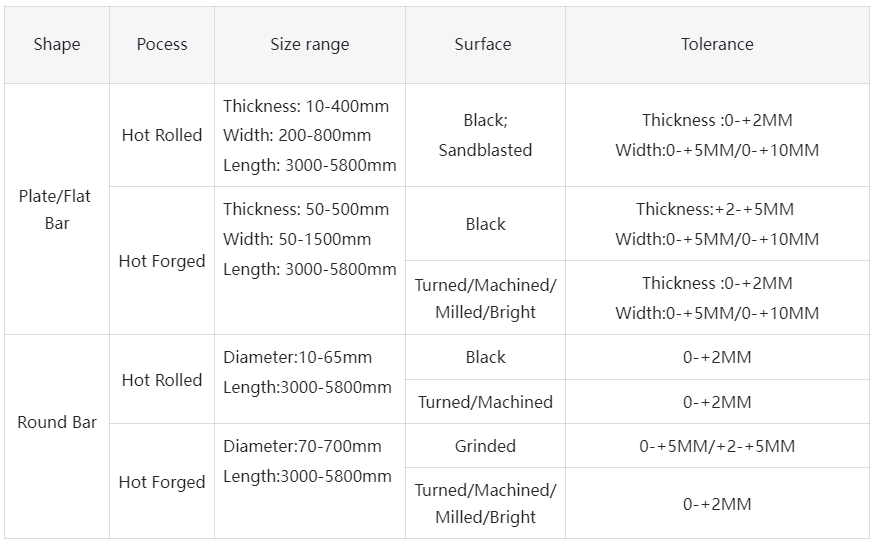

4X5MΦC Tool Steel Size Range

- Hot Rolled Plate/Flat Bar:Thickness: 10-400mm,Width: 200-800mm,Length: 3000-5800mm

- Hot Forged Plate/Flat Bar:Thickness: 50-500mm,Width: 50-1500mm,Length: 3000-5800mm

- Hot Rolled Round Bar: Diameter 10-65mm,Length 3000-5800mm

- Hot Forged Round Bar:Diameter:70-700mm,Length:3000-5800mm

4X5MΦC Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

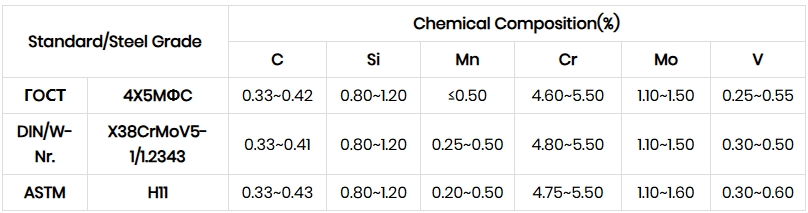

4X5MΦC Tool Steel Chemical Composition

The chemical composition of 4X5MΦC Tool Steel consists of the following key elements:

- Carbon (C): 0.33%–0.42%

- Silicon (Si): 0.80%–1.20%

- Manganese (Mn): ≤0.50%

- Chromium (Cr): 4.60%–5.50%

- Molybdenum (Mo): 1.10%–1.50%

- Vanadium (V): 0.25%–0.55%

These components provide 4X5MΦC Tool Steel with excellent high-temperature resistance, toughness, and heat cracking resistance, ensuring stable performance under high thermal conditions.

4X5MΦC Tool Steel Equivalent Grades

4X5MΦC Tool Steel Specifications

4X5MΦC Tool Steel Customized Options

- Custom Surface Conditions: Black; Sandblasted; Grinded; Turned/Machined/Milled/Bright

- Custom Chemical Composition: Capable of producing standard grades such as GB, DIN, ASTM, JIS, etc. Chemical composition can be custom-produced individually.

- Custom Specifications: Round steel (diameter) and plates (thickness, width) can be custom-produced.

- Professional packaging for long-term storage or extreme transportation conditions: Including black paint spraying on all sides, plastic film wrapping, anti-rust oil spraying, and delivery in wooden cases.

- Custom production according to samples or technical agreements.

- 4X5MΦC Tool Steel Electroslag Remelting (ESR): Premium option with higher purity and isotropic properties for critical applications.

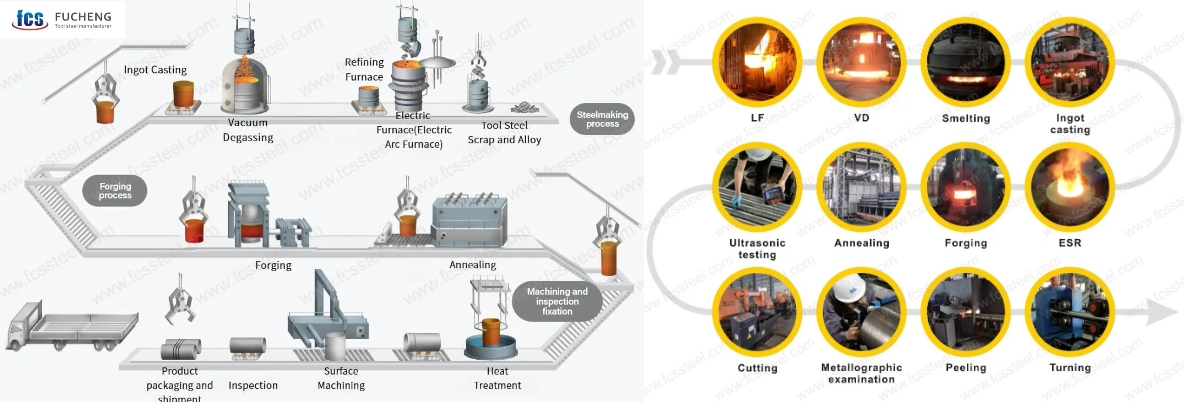

4X5MΦC Tool Steel Smelting process

The manufacturing process for 4X5MΦC Tool Steel involves the following steps:

Electric Furnace (EF) + Ladle Furnace (LF) + Vacuum Degassing (VD) + Hot Rolling / Hot Forging + Annealing.

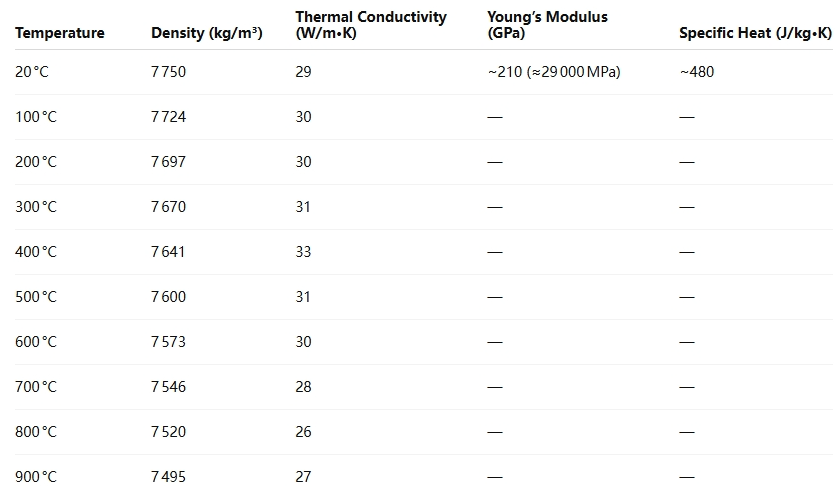

4X5MΦC Tool Steel Physical Properties

- Thermal expansion: ≈11.5 × 10⁻⁶/K between 20–100 °C

- Thermal conductivity increases slightly with temperature, averaging ~29–33 W/m·K

- Density decreases linearly under heat due to thermal expansion

4X5MΦC Tool Steel Mechanical & Performance Properties

At room temperature (quenched + tempered):

- Ultimate tensile strength (σₗ)≈1570–1710 MPa

- Yield strength ≈1320–1540 MPa at 300–400 °C, decreasing to ≈1130–1370 MPa at 500 °C

- Elongation (δ₅) ~10–12%, reduction of area (ψ) ~48–52% across temperature range

- Charpy impact toughness (KCU): ~50–62 J at room and elevated temperatures

4X5MΦC Tool Steel Product Applications

-

- Hot forging dies:It is used for hammer forging and press forging dies, adaptable to high-temperature impact loads, and has strong heat crack resistance.

- Die-casting mold:High-pressure die-casting molds suitable for non-ferrous metals such as aluminum alloys and magnesium alloys, featuring excellent thermal fatigue life.

- Hot extrusion die:Hot extrusion dies for materials such as steel, copper and aluminum have strong resistance to high-temperature plastic deformation.

- Hot scissors blades and punches;It is suitable for manufacturing high-temperature shearing blades and punching punches, featuring excellent wear resistance and toughness.

- Hot stamping forming die:It is applied in high-temperature and high-pressure mold scenarios such as automotive hot forming and hot stamping of structural parts.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |