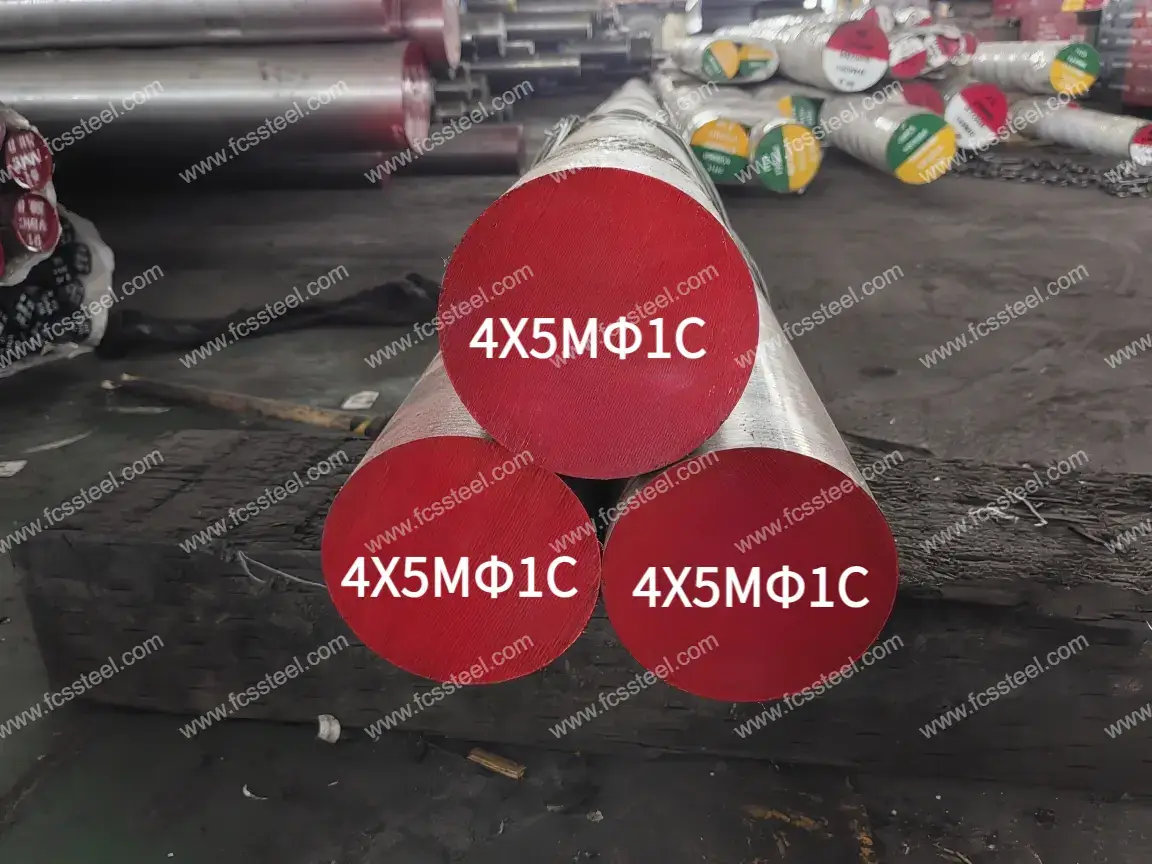

4X5MΦ1C Tool Steel

9XBГ tool steel is a high performance cold work mould steel with excellent wear resistance, high hardness and good heat treatment stability. The corresponding ASTM standard is O1 tool steel, and the corresponding DIN/W-Nr standard is 100MnCrW4/1.2344. 9XBГ tool steel is especially suitable for stamping moulds, precision gauges, demanding cutting tools, and all kinds of industrial moulds. 9XBГ tool steel can be supplied with a wide range of specifications and customized machining services to meet the stringent process requirements of different manufacturers. FCS Tool Steel Factory can offer a wide range of specifications and custom machining services to meet the stringent process requirements of different manufacturers.

4X5MΦ1C Tool Steel Product Introduction

4X5MΦ1C tool steel is a high-performance hot work tool steel designed for moulds subjected to high temperatures and mechanical stresses, with a balance of hardness, toughness and resistance to thermal fatigue comparable to DIN 1.2343 (H11) tool steels. Its corresponding Japanese standard JIS is SKD61 tool steel, Swedish standard ASSB is 8407, Austrian BOHLER is W302 tool steel, Chinese standard GB is 4Cr5MoSiV1. It has a high hardness and impact toughness, suitable for tools subjected to mechanical stress. Excellent thermal stability and wear resistance enable it to withstand thermal cycling and stress typical of hot work environments. And good resistance to thermal fatigue makes it ideal for moulds that undergo repeated heating and cooling.

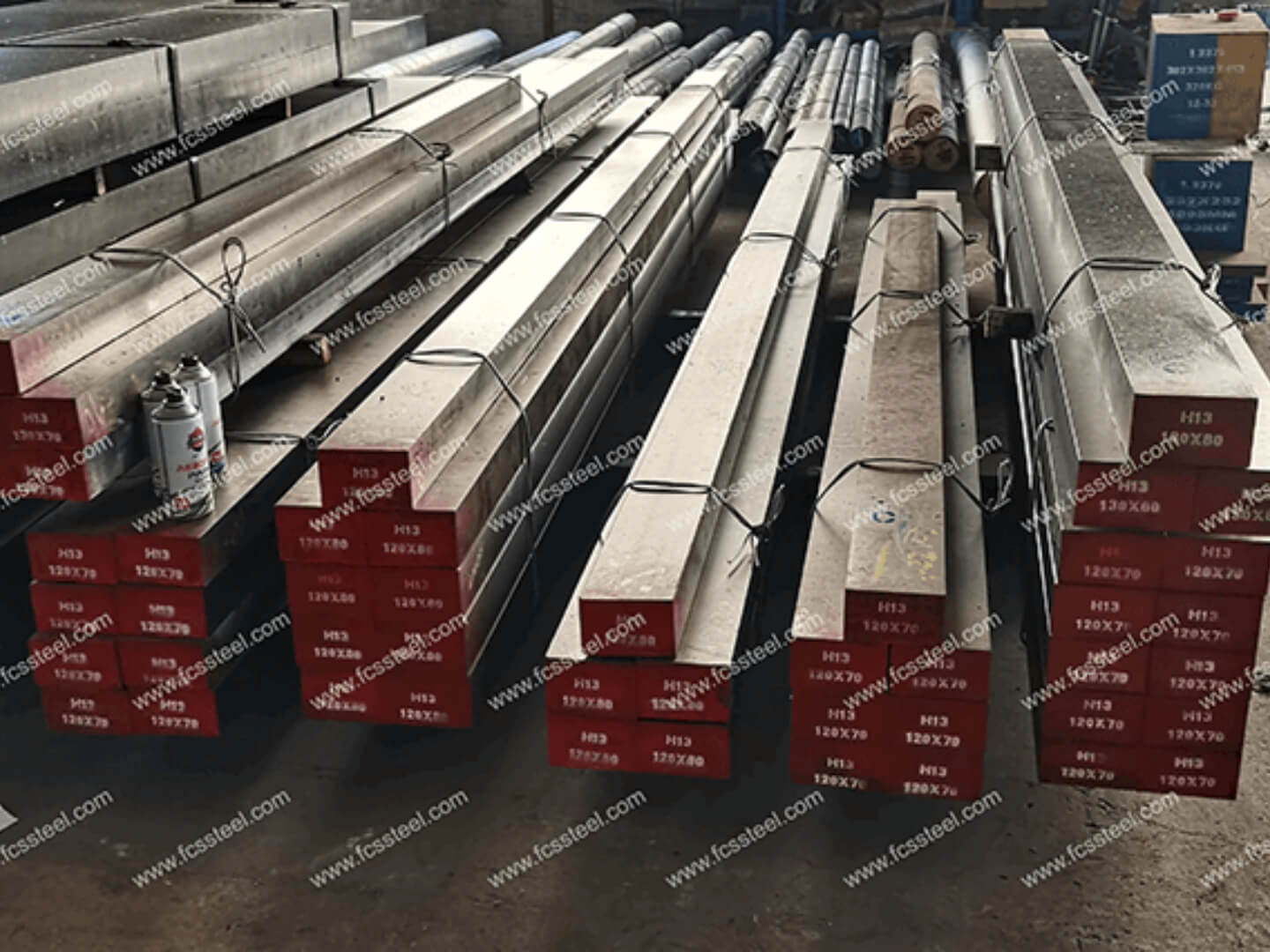

4X5MΦ1C Tool Steel Types and Options

The table below shows the size range, surface condition and tolerance details for 4X5MΦ1C Tool Steel:

4X5MΦ1C Tool Steel Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

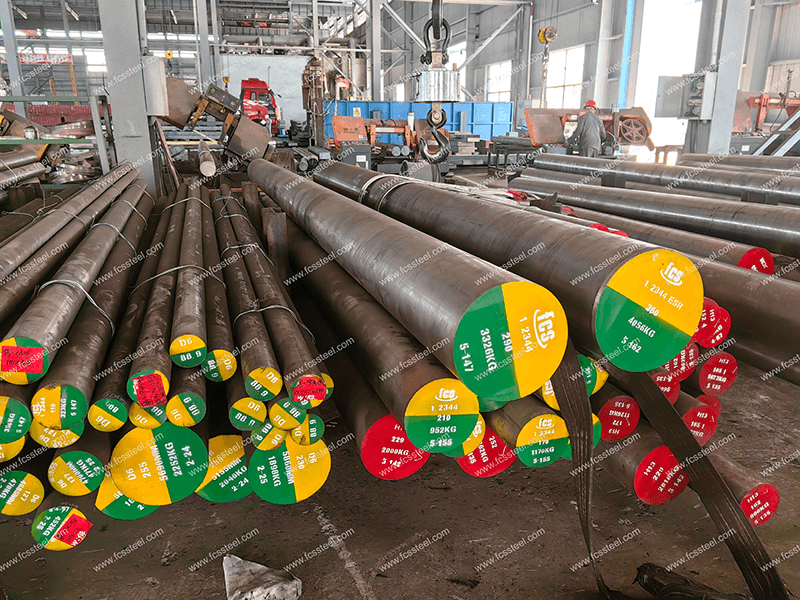

- 4X5MΦ1C Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

4X5MΦ1C Tool Steel Chemical Composition

4X5MΦ1C Tool Steel Heat Treatment Process

The heat treatment process for 4X5MΦ1C tool steel generally includes four main steps: annealing, preheating, quenching, and tempering. The purpose is to achieve the desired hardness, toughness, and heat resistance. The specific process is as follows:

Annealing

Annealing A softening treatment to remove casting or forging stresses, to obtain a refined and homogeneous ferrite + pearlite organisation, to reduce hardness and to improve machinability. Annealing is carried out at the outset to soften the virgin material in preparation for subsequent heat treatment. The steel cools slowly after annealing.

- Heating Temperature: Approximately 750–780°C

- Holding Time: Depending on the workpiece size, typically 1–2 hours

- Cooling Method: Furnace cooling or controlled slow cooling to transform the structure into uniform pearlite + ferrite.

- Purpose: To soften the steel, relieve forging/casting stresses, improve machinability, refine the grain structure, and lay the foundation for subsequent heat treatment.

2. Preheating

Preheating is not a separate softening step, but rather a buffer heating for subsequent quenching to avoid thermal stress cracking during quenching due to too rapid heating. Preheating is carried out after annealing and before quenching.

- Gradually heat to approximately 600–650°C to reduce thermal stress during quenching and prevent crack formation.

- The preheating stage can be carried out in multiple steps, such as holding at 300–400°C first, then heating to 600–650°C for insulation.

3. Quenching

- Heat to 1000–1040°C (austenitizing temperature) and maintain for a sufficient time to fully austenitize the steel.

- Rapidly quench using a cooling medium, commonly oil or gas (depending on the steel thickness and workpiece shape), to form a martensitic structure and achieve high hardness.

4.Tempering

- After quenching, the steel is usually hard and has high internal stresses. Tempering is required to improve toughness and reduce brittleness.

- Tempering temperature is typically 550–650°C. The tempering time depends on the workpiece size and performance requirements. Double tempering is usually performed to ensure uniform and stable properties.

- After tempering, the hardness is generally controlled at around 48–52 HRC. The tempering parameters can be adjusted according to specific applications.

5. Solution Treatment and Aging (if applicable)

- For certain specific applications, solution treatment and aging may be performed to enhance material stability and mechanical properties.

It should be noted that specific heat treatment parameters can be appropriately adjusted according to the actual workpiece size, service requirements, and equipment conditions. Generally speaking, the key to heat treatment of 4X5MΦ1C is quenching at an appropriate austenitizing temperature and a reasonable tempering process to ensure its strength, toughness, and thermal stability at high temperatures.

4X5MΦ1C Tool Steel Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

4X5MΦ1C Tool Steel Technical Specifications

4X5MΦ1C Tool Steel Product Applications

- Precision Stamping Tooling

- Cold forming tools

- Industrial Cutting Tools

- Plastic Injection Moulds

- Powder pressing moulds

- Automotive Manufacturing

- Aerospace components

- Electronics Manufacturing

- Medical device manufacturing

- Heavy Machinery

4X5MΦ1C Tool Steel Competitive Advantage Comparison

4X5MΦ1C Tool Steel Customer Success Stories

4X5MΦ1C Tool Steel Pricing Structure Information

4X5MΦ1C Tool Steel Frequently Asked Questions

Q: How does the machinability of 4X5MΦ1C compare to D2 tool steel?

A: The machinability of 4X5MΦ1C in the annealed condition is about 65% of D2. It requires slightly reduced cutting speeds, rigid tool setups, and sharp carbide tools with appropriate geometry. However, improved wear resistance and performance characteristics justify additional machining considerations. Our machining guide provides optimised parameters for efficient machining.Q: Is 4X5MΦ1C suitable for hot work applications?

A: The standard 4X5MΦ1C grade is suitable for applications up to 500°C. For higher temperature applications, we recommend the 4X5MΦ1C-HT variant, which is specially modified for enhanced high temperature stability up to 550°C. For applications above this temperature, we recommend exploring our range of specialised hot work tool steels.Q: What surface treatments or coatings are compatible with 4X5MΦ1C?

A: 4X5MΦ1C is compatible with most common surface treatments, including nitriding, physical vapour deposition coatings (TiN, TiCN, TiAlN, CrN) and chemical vapour deposition coatings. When properly prepared, these coatings can further enhance wear resistance, reduce friction, and extend tool life. Our Surface Finish Compatibility Guide provides detailed recommendations for specific applications.Q: Is 4X5MΦ1C suitable for plastic injection moulding applications?

A: Yes, 4X5MΦ1C is particularly suitable for moulds processing abrasive or glass-filled plastics where wear resistance is critical. It can be polished to a high surface finish (Ra 0.05μm) and maintain this finish over long production runs with minimal mould maintenance. For corrosive plastics, the 4X5MΦ1C-CR variant with enhanced corrosion resistance is recommended.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |