4Cr5MoSiV Tool Steel

The chemical ratio of 4Cr5MoSiV tool steel is particularly strengthened with Mo, Si and V elements, which endows it with excellent high-temperature strength, thermal hardness and thermal fatigue resistance, making it suitable for various mold applications that require high temperature, high pressure and repeated thermal shock.

4Cr5MoSiV Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

4Cr5MoSiV Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

4Cr5MoSiV Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

What is 4Cr5MoSiV Tool Steel?

4Cr5MoSiV is a domestic hot work tool steel developed in accordance with the GB/T 1299 series standards. It is one of the most important steel grades in China corresponding to international H13 (DIN 1.2344 / JIS SKD61 / ASTM H13).

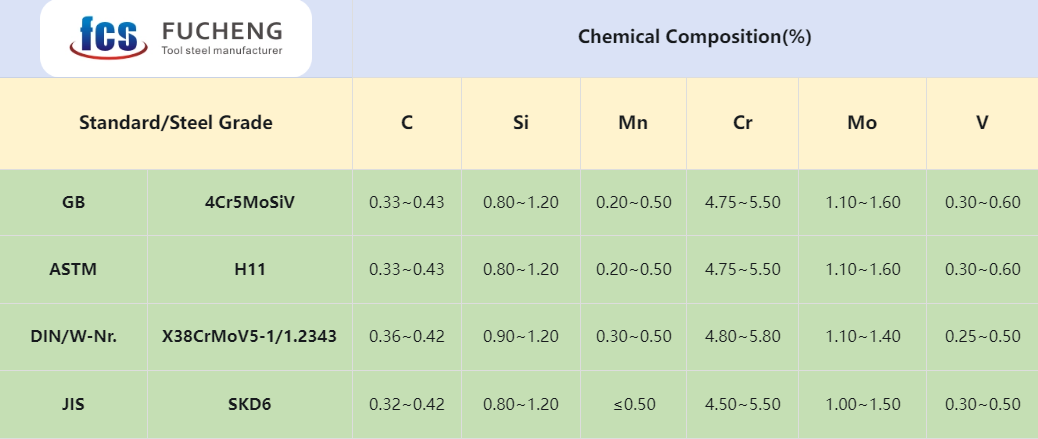

International Equivalent Grades of 4Cr5MoSiV Tool Steel

Chemical Composition of 4Cr5MoSiV Tool Steel

4Cr5MoSiV Steel Product Specifications

4Cr5MoSiV Steel Heat Treatment and Performance Indicators

- Annealing: 860-890 °C slow cooling followed by furnace cooling. Annealing hardness approximately ≤229 HBW (for ease of machining).

- Quenching: 1020-1080 °C followed by oil cooling or air cooling, with hardness reaching 56-58 HRC; The hardness of large cross-sections is slightly lower.

- Tempering: Double tempering at 560-580 °C, with the final hardness stabilized at 47-49 HRC; Low-temperature tempering can also be used to relieve stress.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |