4Cr3Mo3SiV Tool Steel

Under high-temperature impact conditions of 600℃, traditional die steels often fail prematurely due to thermal fatigue cracks. 4Cr3Mo3SiV, as a hot work die steel in accordance with the Chinese national standard (GB/T 1299-2014), achieves a breakthrough balance between high-temperature strength and toughness through a golden ratio of 3.0-3.75% chromium + molybdenum-vanadium composite strengthening.

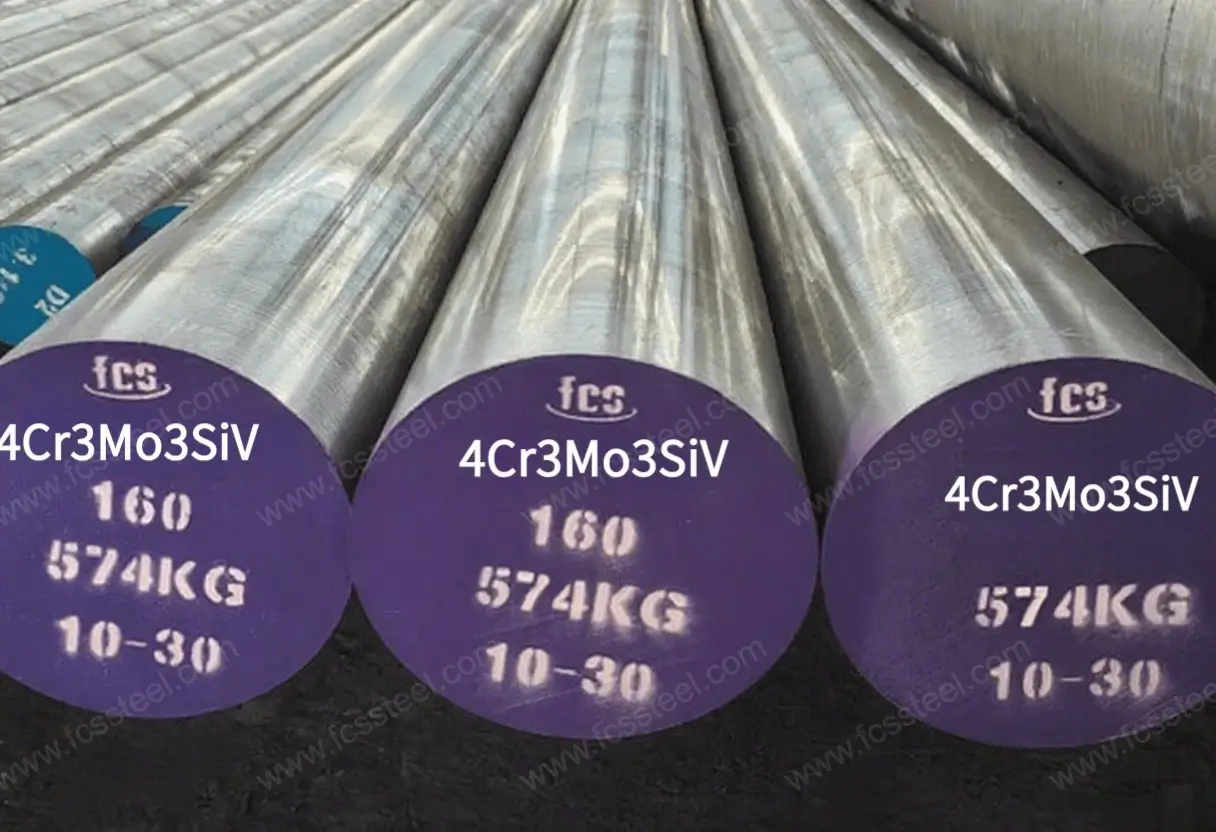

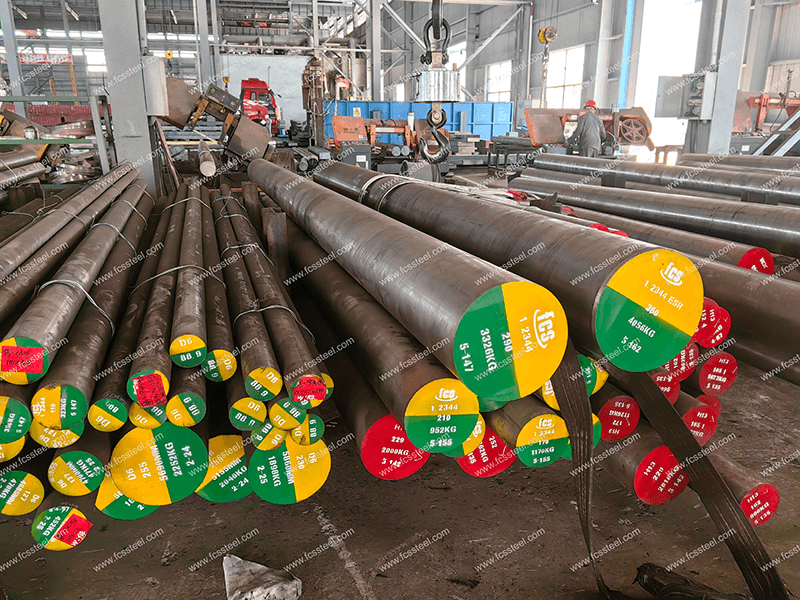

4Cr3Mo3SiV Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

4Cr3Mo3SiV Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

4Cr3Mo3SiV Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

What is 4Cr3Mo3SiV Tool Steel?

4Cr3Mo3SiV belongs to the hot working tool steel series in the Chinese GB/T 1299 standard and is derived from the American H10 steel. It combines excellent hardenability, high-temperature hardness and impact toughness, and performs outstandingly in heat-resistant die applications, being highly favored by hot stamping and hot forging processes.

International Equivalent Grades of 4Cr3Mo3SiV Tool Steel

Chemical Composition of 4Cr3Mo3SiV Tool Steel

4Cr3Mo3SiV Steel Product Specifications

4Cr3Mo3SiV Tool Steel Service capacity

Processing and inspection services: We offer sawing, mechanical processing, heat treatment, ultrasonic flaw detection, hardness and metallographic testing, etc. Customized supply is supported.

4Cr3Mo3SiV Tool Steel Key performance highlights

- It has excellent hardenability and is suitable for making thick cross-section mold parts.

- It has excellent toughness and a longer service life compared to 3Cr2W8V.

- High-temperature hardness retention support, suitable for use in environments ranging from 400 to 500 °C.

- It has strong heat fatigue resistance and is often used in hot stamping and hot forging parts.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 180 × 40 × 30 cm |