440C Tool Steel | 1.4125 | X105CrMo17

FCS Tool Steel’s premium 440C/1.4125/X105CrMo17 stainless steel represents the pinnacle of martensitic stainless steel technology, addressing the core challenge of combining superior hardness with effective corrosion resistance.

Precision component manufacturers are constantly faced with the challenge of balancing wear resistance with environmental durability. Our specially processed 440C grade material provides an innovative solution to this dilemma, with its homogeneous microstructure and optimised distribution of carbides enabling parts to maintain their structural integrity and dimensional stability under severe service conditions.

The results are clear: longer component life, fewer maintenance intervals, and greater performance reliability in critical applications – where failure is never acceptable.

440C Tool Steel | 1.4125 | X105CrMo17 Product Introduction

440C Stainless Steel (American Standard AISI/ASTM)

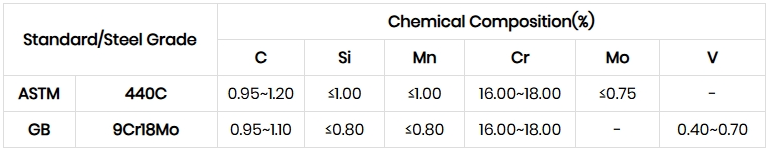

The chemical composition of 440C stainless steel is carbon (0.95%-1.20%), chromium (16.00%-18.00%), and molybdenum (≤0.75%), supplemented by the limiting elements silicon (≤1.00%) and manganese (≤1.00%). After quenching (1010-1070°C oil-cooled) and low-temperature tempering (100-300°C), the hardness can reach HRC 58-62, tensile strength 560-1000 MPa, elongation 15%-18%.

The metallographic organisation of the material is typical martensite, with magnetic properties and moderate corrosion resistance, stable in mild corrosive environments, but prone to pitting corrosion in chloride or strong acid environments. Its high temperature dimensional stability is good, but it is weak to withstand dynamic loads.

1.4125 Stainless Steel (W-Nr/DIN)

The chemical composition of 1.4125 stainless steel is identical to that of 440C: carbon (0.95%-1.10%), chromium (16.00%-18.00%). Physical parameters include a density of 7.7-7.78 g/cm³, a modulus of elasticity of 200-215 GPa, and a coefficient of thermal expansion (20-100°C) of 10.2-11.6×10-⁶/K. Heat treatment is subject to 980 -1070°C oil quenching and 200-300°C tempering, the hardness can be increased to HRC 55-60, yield strength ≥ 440 MPa, tensile strength ≥ 690 MPa.

material shows high wear resistance and martensitic phase transition properties, corrosion resistance in oxidising media (e.g. dilute nitric acid) The corrosion resistance is good in oxidising media (e.g. dilute nitric acid) (corrosion rate <0.1 mm/a), but decreases significantly in reducing acids (e.g. hydrochloric acid) (>10.0 mm/a). Its hardness in the annealed state is ≤225 HBS, and after quenching it is necessary to avoid welding to prevent cracking.

X105CrMo17 Stainless Steel (DIN/W-Nr)

X105CrMo17 stainless steel has a composition of carbon (0.95%-1.10%) and chromium (16.00%-18.00%), which is highly overlapping with 440C and 1.4125, with only a slightly higher upper limit of carbon content. Heat treatment is 1070°C oil quenching + 200-300°C tempering, hardness up to HRC 54-60, bending fatigue strength at 961 N stress of 6.3 × 10⁴-8.4 × 10⁴ times cycles.

The material has a martensitic organisation reinforced with high-carbon chromium-molybdenum, and its corrosion resistance is stable (corrosion depth <1.0 mm/a) in nitric acid (concentration ≤20%), but deteriorates sharply with increasing concentration and temperature in acetic or phosphoric acid environments. Its thermal stability remains good up to 400°C, but there is no significant increase in thermal conductivity at high temperatures.

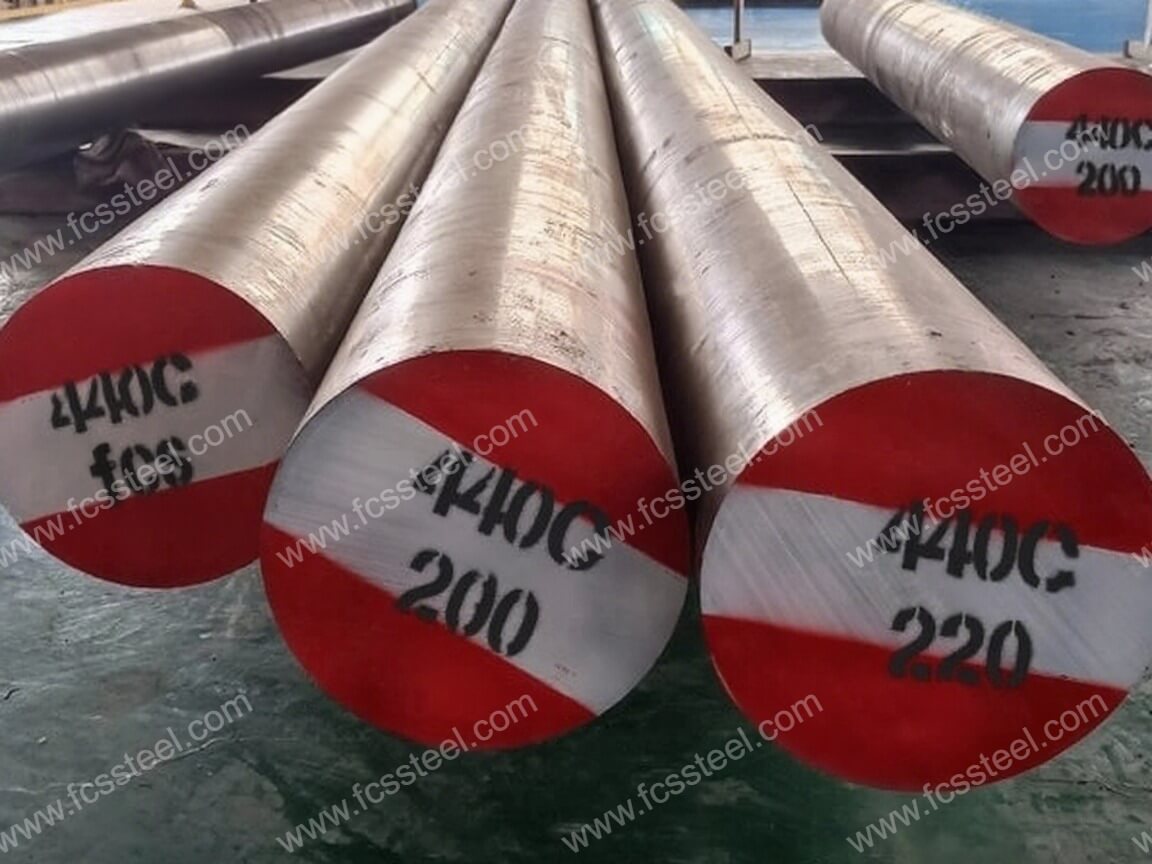

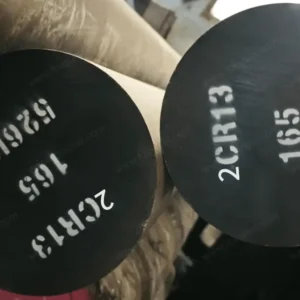

440C Tool Steel | 1.4125 | X105CrMo17 Types and Options

The table below shows the size range, surface condition and tolerance details for440C/1.4125/X105CrMo17 Tool Steel:

440C Tool Steel | 1.4125 | X105CrMo17 Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- 440C/1.4125/X105CrMo17 Stainless Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

440C Tool Steel | 1.4125 | X105CrMo17 Chemical Composition

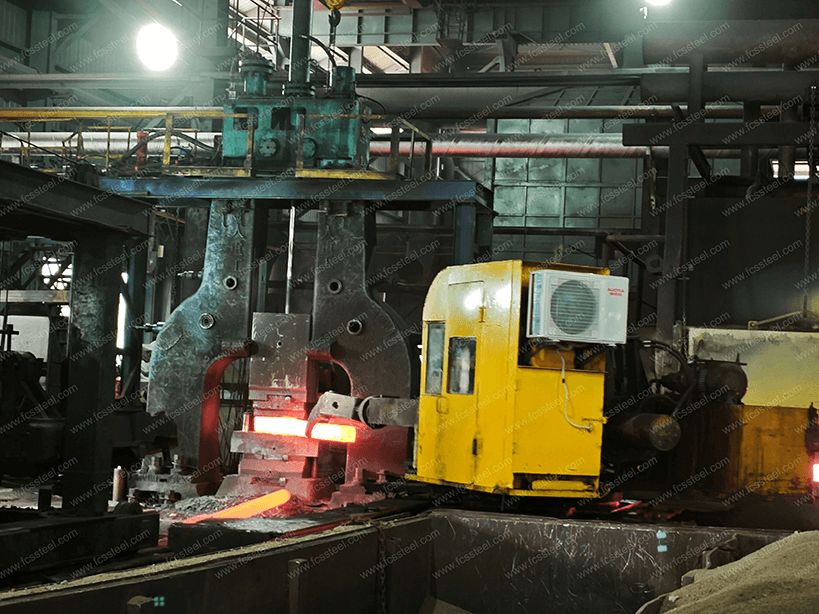

440C Tool Steel | 1.4125 | X105CrMo17 Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

440C Tool Steel | 1.4125 | X105CrMo17 Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

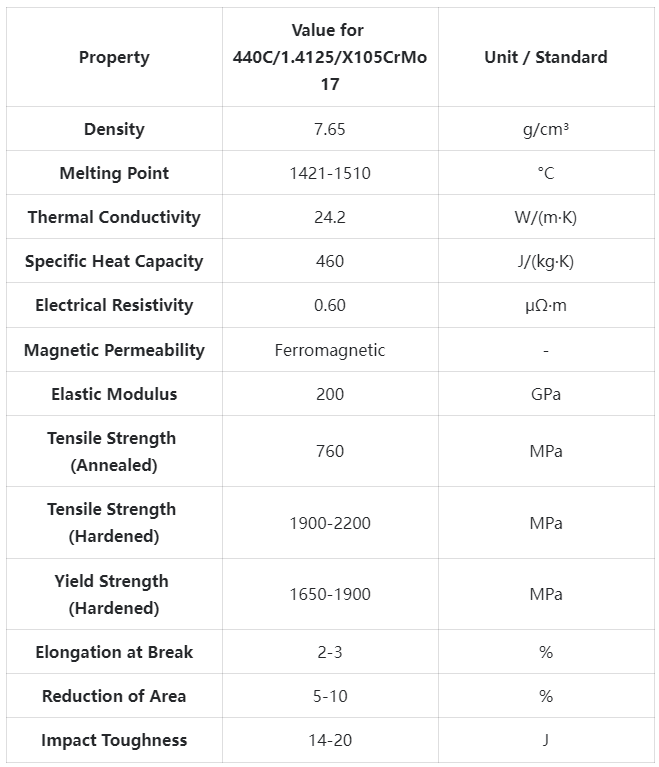

440C Tool Steel | 1.4125 | X105CrMo17 Technical Specifications

440C Tool Steel | 1.4125 | X105CrMo17 Product Applications

Key Usage Scenarios

Aerospace Precision Ball Bearings

Our 440C stainless steel is the material of choice for critical aerospace bearings where reliability is essential. In high-altitude environmental conditions, conventional bearing materials often fail prematurely due to accelerated corrosion. 440C's unique combination of hardness and corrosion resistance allows bearing designs to maintain precision tolerances over thousands of hours of fluctuating temperature and humidity conditions. These bearings typically last 30-45% longer than standard chrome steel bearings in the same applications.

Surgical Instruments and Medical Devices

Medical device manufacturers rely on our 1.4125 stainless steel for high-end surgical instruments that require superior edge retention and corrosion resistance. The material's ability to maintain a sharp cutting edge while withstanding repeated sterilisation cycles makes it ideal for precision surgical tools. Our specially machined medical-grade variants undergo additional testing to ensure biocompatibility and meet stringent cleanliness requirements, allowing surgeons to rely on these instruments to maintain consistent performance over hundreds of surgeries.

High-performance valve components

Industrial valve systems operating in harsh environments benefit from the wear and corrosion resistance of X105CrMo17 components. Seats, balls and stems made from our material maintain sealing integrity when handling abrasive media or corrosive chemicals. Case studies have shown that upgrading from standard stainless steel parts to our high-carbon martensitic stainless steel options results in maintenance intervals being extended by 40-60%, directly reducing downtime and maintenance costs in critical industrial processes.

Precision Cutting Tools and Inserts

Our 440C grade material is widely used in high performance industrial cutting tools and inserts where edge retention is critical. The combination of high hardness and reasonable toughness makes it suitable for slitting blades, industrial shears and precision cutting instruments. Manufacturers report sharpening or replacement intervals that are 3-5 times longer than lower-grade stainless steel options, significantly increasing productivity and reducing operating costs.

Industry-Specific Applications

- Aerospace: control mechanism components: landing gear bearings and bushings; hydraulic system valve components; fasteners for critical structural applications; instrumentation components.

- Medical & Pharmaceutical: Surgical cutting instruments; endoscopic equipment; dental instruments; medical implant parts (temporary); laboratory test equipment;

- Food Processing: Highly abrasion-resistant cutting blades; industrial mixer components; abrasive media pump components; nozzles and sprays; precision measuring instruments.

- Oil & Gas: Downhole Tool Parts; Valve Seats & Stems; Sensor Housings; Pump Plungers & Components; Throttle Parts

- Automotive Transportation: Fuel Injection Parts; ABS System Parts; Bearing Rings & Balls; Valve Train Parts; Specialty Fasteners.

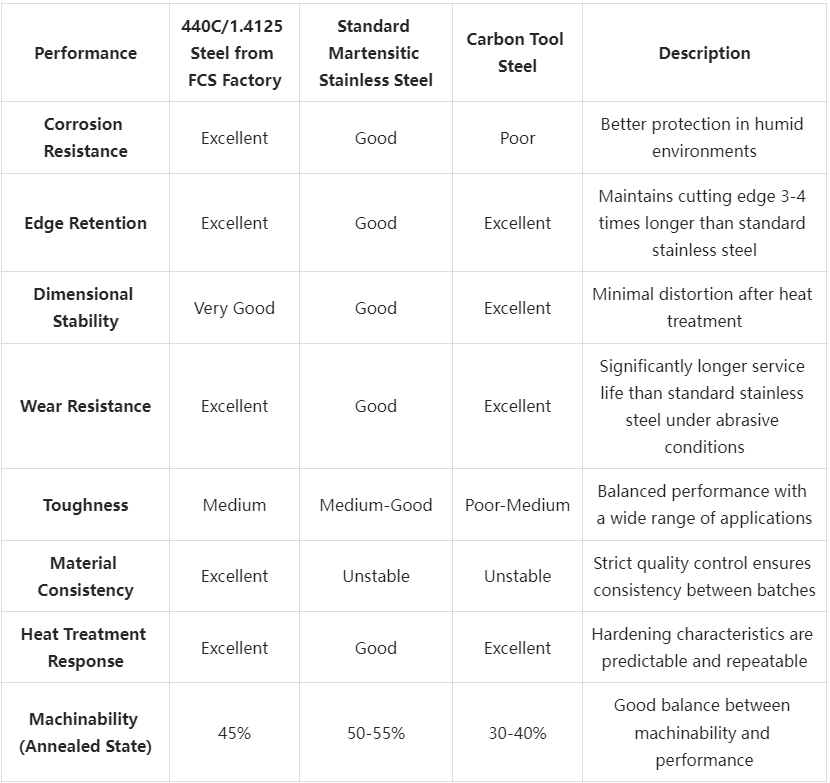

440C Tool Steel | 1.4125 | X105CrMo17 Competitive Advantage Comparison

440C Tool Steel | 1.4125 | X105CrMo17 Customer Success Stories

440C Tool Steel | 1.4125 | X105CrMo17 Pricing Structure Information

440C Tool Steel | 1.4125 | X105CrMo17 Frequently Asked Questions

Q: How does 440C/1.4125/X105CrMo17 compare to other martensitic stainless steels such as 420 or 431?

A: 440C has a significantly higher carbon content (0.95-1.20 per cent compared to 0.15-0.40 per cent for 420), which results in higher hardness and wear resistance after heat treatment. The higher chromium content also provides better corrosion resistance than 420. Compared to 431, 440C offers superior wear resistance and slightly better corrosion resistance, but is slightly less tough.Q: How does 440C compare to D2 tool steel in cutting applications?

A: 440C offers approximately 80-85% of the wear resistance of D2 tool steel while providing significantly better corrosion resistance. For applications where both properties are required, 440C generally provides a better balance. When the only consideration is maximum wear resistance, D2 may be preferred.Q: What heat treatment is recommended to obtain maximum hardness?

A: Optimum heat treatments include austenitising at 1010-1065°C (1850-1950°F), quenching in oil, and then tempering at 150-180°C (300-350°F). For maximum dimensional stability, a triple tempering process is recommended, usually with deep cooling between the first and second tempering cycles.Q: Is this material magnetic?

A: Yes, 440C/1.4125/X105CrMo17 is ferromagnetic in both the annealed and hardened states and is suitable for applications where magnetism is required.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |