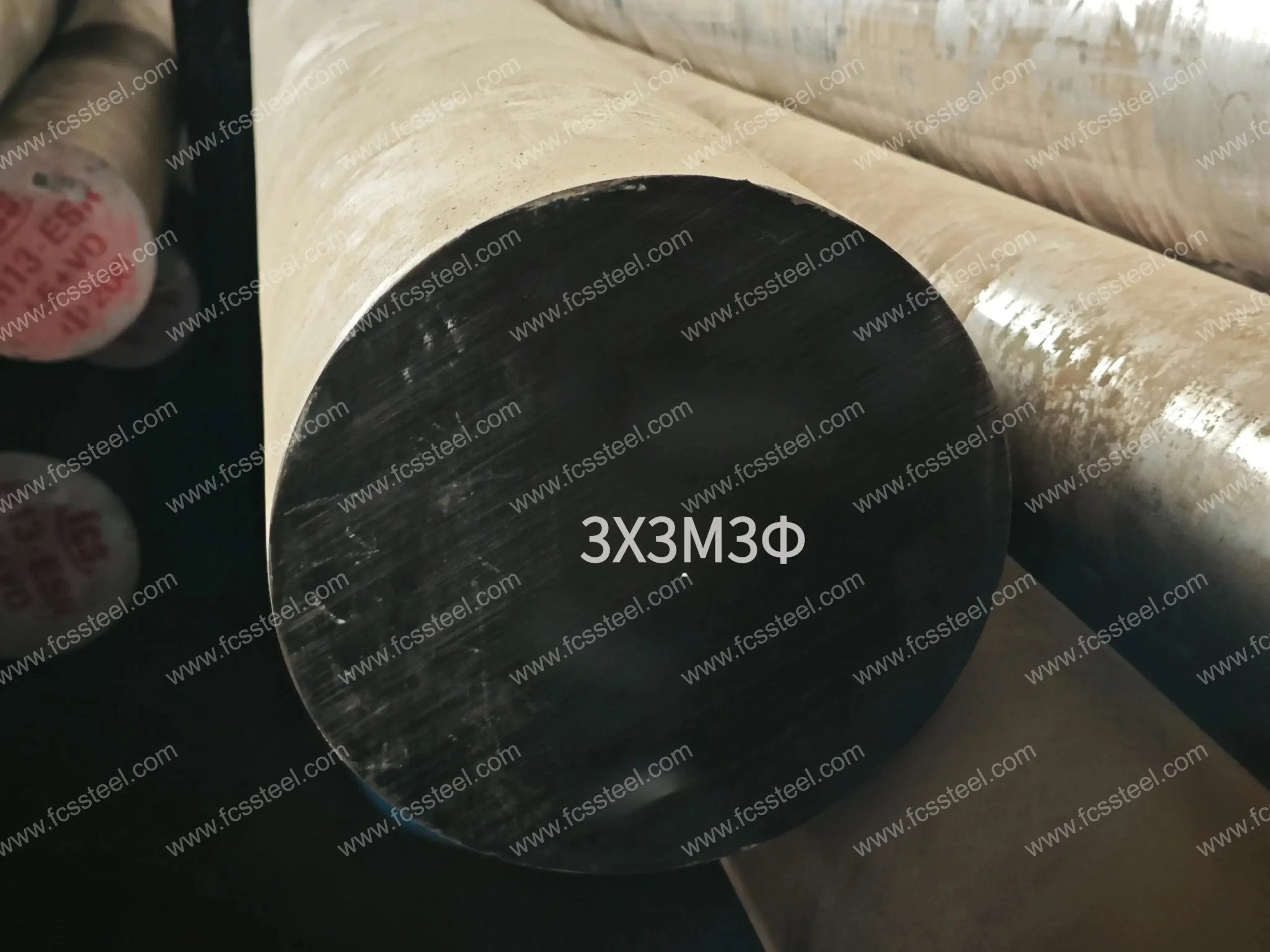

3X3M3Φ Tool Steel

3X3M3Φ is a Russian high-strength hot work die tool steel, widely used in hot casting, forging and hot cutting applications where high temperatures and frequent cooling are required. It belongs to the hot work steel series of GOST standard, combining high hardness, excellent heat fatigue resistance and toughness, especially suitable for aluminium-copper alloys, high-strength materials for hot forming tools.

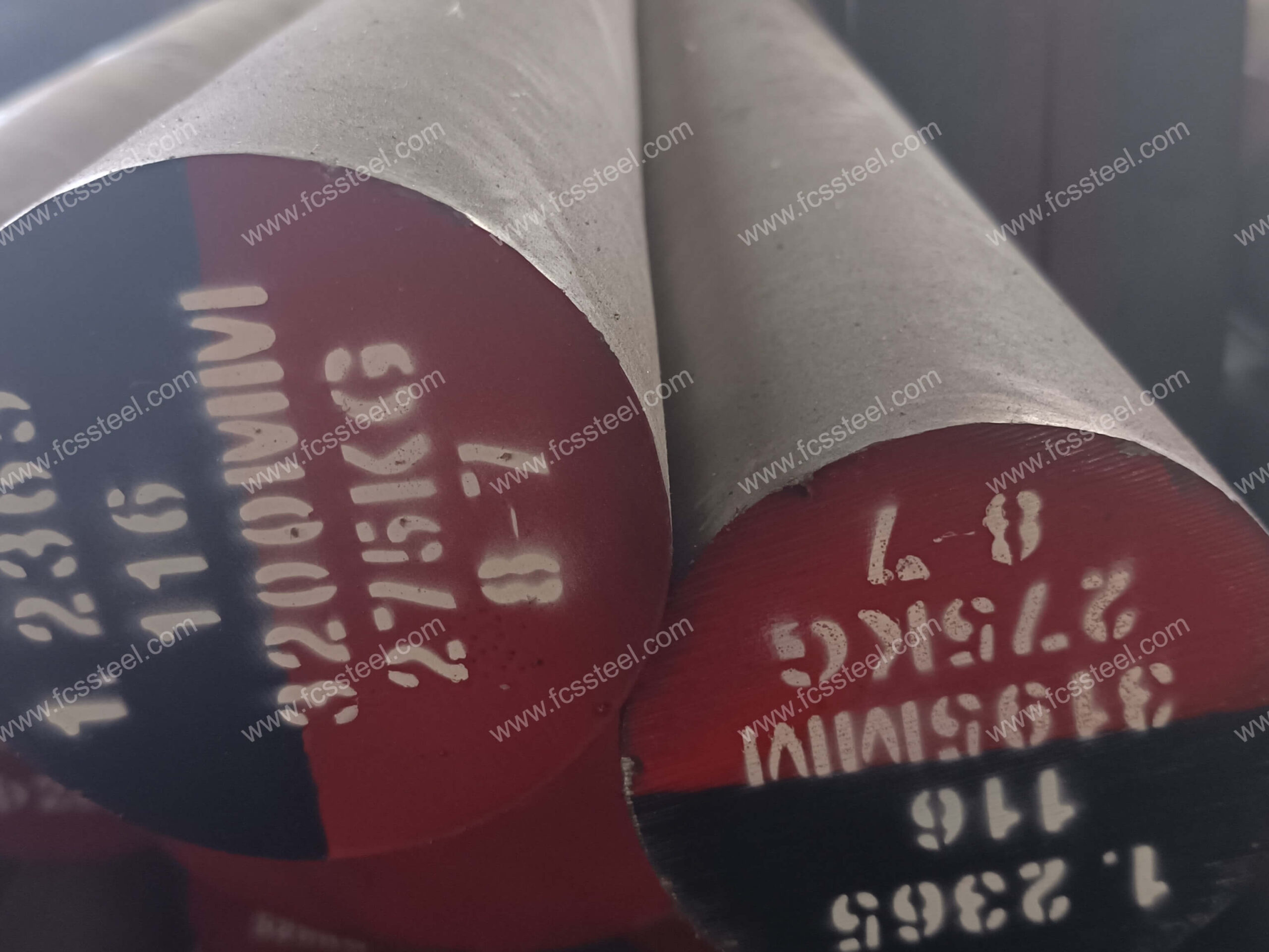

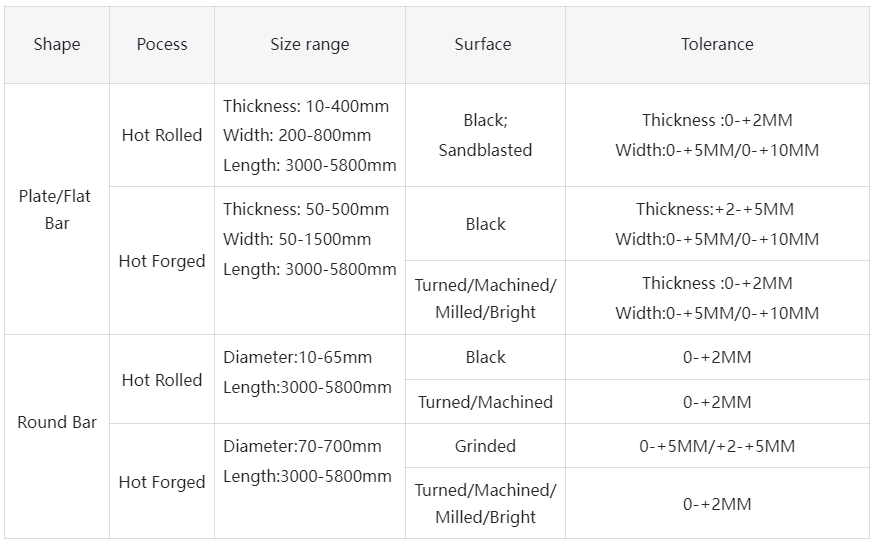

3X3M3Φ Tool Steel Size Range

- Hot Rolled Plate/Flat Bar:Thickness: 10-400mm,Width: 200-800mm,Length: 3000-5800mm

- Hot Forged Plate/Flat Bar:Thickness: 50-500mm,Width: 50-1500mm,Length: 3000-5800mm

- Hot Rolled Round Bar: Diameter 10-65mm,Length 3000-5800mm

- Hot Forged Round Bar:Diameter:70-700mm,Length:3000-5800mm

3X3M3Φ Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

3X3M3Φ Tool Steel Chemical Composition

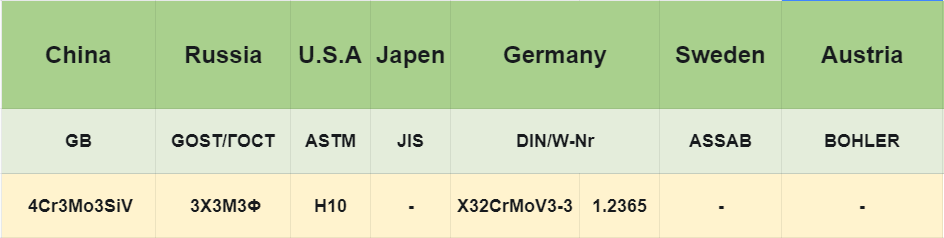

3X3M3Φ Tool Steel Equivalent Grades

The approximate correspondence of 3X3M3Φ tool steel in the standards of various countries is as follows:

- Russia (GOST): 3Х3М3Ф

- China (GB): 4Cr3Mo3SirV (referred to as H10 steel)

- Germany (DIN / W-Nr): 1.2365 (X32CrMoV3-3)

- Japan (JIS): SKD62 / SKD7 (closest to SKD62 or 7)

- USA (AISI/ASTM): H10 steel

- Sweden (ASSAB): 8407 series

- Austria (BÖHLER): W302

3X3M3Φ Tool Steel Specifications

3X3M3Φ Tool Steel Customized Options

- Custom Surface Conditions: Black; Sandblasted; Grinded; Turned/Machined/Milled/Bright

- Custom Chemical Composition: Capable of producing standard grades such as GB, DIN, ASTM, JIS, etc. Chemical composition can be custom-produced individually.

- Custom Specifications: Round steel (diameter) and plates (thickness, width) can be custom-produced.

- Professional packaging for long-term storage or extreme transportation conditions: Including black paint spraying on all sides, plastic film wrapping, anti-rust oil spraying, and delivery in wooden cases.

- Custom production according to samples or technical agreements.

- 3X3M3Φ Tool Steel Electroslag Remelting (ESR): Premium option with higher purity and isotropic properties for critical applications.

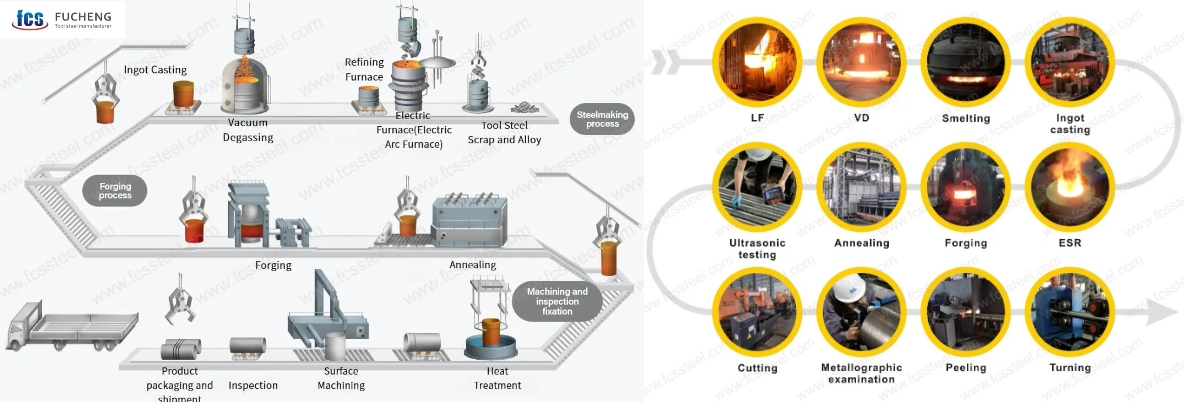

3X3M3Φ Tool Steel Smelting process

- Steel composition: electric furnace or vacuum furnace package refining process, strict control of carbon and alloying element ratio;

- Forging/rolling: hot working temperature 1180→850 ℃, slow cooling;

- Quenching: heating to 1040 ℃ oil cooling, control the quenching cooling rate, reduce cracks;

- Tempering: 500-600 ℃ tempering 2 h, can be several times, until the target hardness and toughness. After heat treatment grain rating to meet the standard requirements.

3X3M3Φ Tool Steel Physical Properties

Typical physical parameters at room and elevated temperatures are as follows (varies from 20°C to 900°C):

- Modulus of elasticity: approx. 207 GPa (20°C), decreasing to 177 GPa at 300°C

- Density: 7828 kg/m³ at 20°C

- Thermal conductivity: ≈32 W/(m-K) at 20°C, 36 W/(m-K) at 400-500°C

- Specific heat capacity: with the temperature increase from 314 J/kg-K (20 ℃) to 1151 J/kg-K (900 ℃)

- Resistivity: 20℃ ≈314 nΩ-m, to 900℃ to 1151 nΩ-m

3X3M3Φ Tool Steel Mechanical & Performance Properties

- Hardness and strength: quenched at 1040 ℃, oil cooled and tempered at 550-600 ℃, the hardness can reach 46-50 HRC. room temperature tensile strength of about 1670 MPa, yield strength of about 1470 MPa, impact toughness of KCU about 49 J/cm².

- High-temperature strength: 500-600 ℃ still has good strength (σ_B ≈ 1270-1450 MPa), hardness maintained ≈ 44-48 HRC.

- Thermal fatigue and crack resistance: excellent thermal hardness, hardness of about 47 HRC at 590°C for 2 h, adaptable to thermal cycling and thermal shock.

3X3M3Φ Tool Steel Product Applications

3X3M3Φ is widely used in hot casting, hot forging and hot cutting tools, such as:

- Copper and aluminium alloy casting moulds, hot forging moulds (crank, connecting rod type)

- Hot shear tools, high-pressure hot extrusion moulds

- Hot cutting tools, automotive parts forming parts, etc.

Use cases show that compared with 5CrNiMo, H13, etc., the life can be increased by 2 to 4 times or more.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |