3X2B8Φ Tool Steel

3X2B8Φ Tool Steel is a high-performance cold/hot composite tool steel of Russian origin (ГОСТ standard) with excellent impact resistance and good wear resistance for composite moulding and precision cutting. The ‘Φ’ in the designation may refer to specific microalloying elements or optimised process markings.

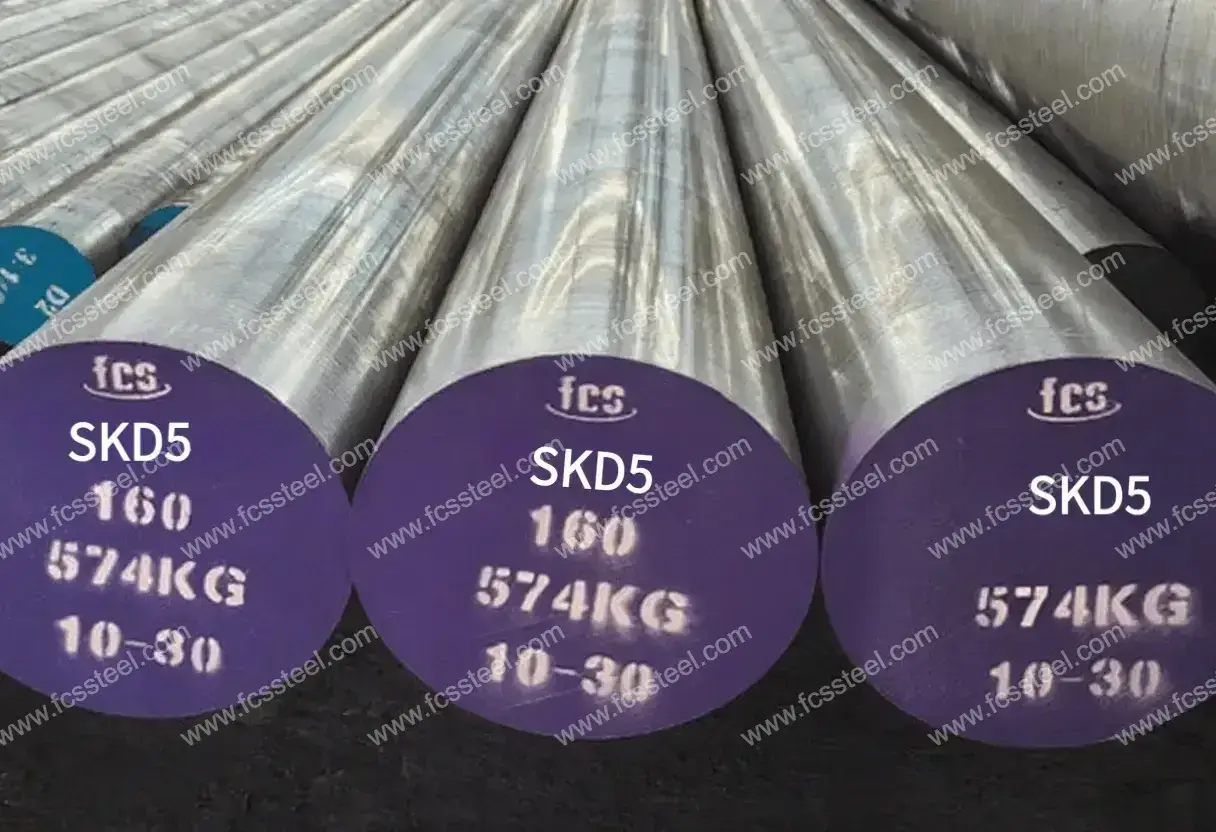

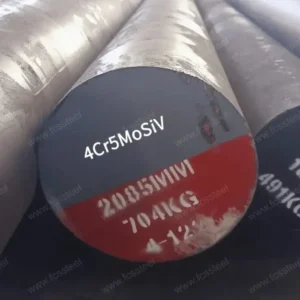

Overall, 3X2B8Φ Tool Steel belongs to the medium-high alloyed tool steel series, which combines carbon, chromium, vanadium and molybdenum elements, and undergoes a fine smelting and heat treatment process to provide performance comparable to the well-known standard tool steels on the market, with a balance of rigidity and toughness.The corresponding American ASTM grade for 3X2B8Φ is H21, the Japanese JIS grade is SKD5, the German DIN/W-Nr grade is X30WCrV9-3/1.2581, and the Chinese standard GB grade is 3Cr2W8V.

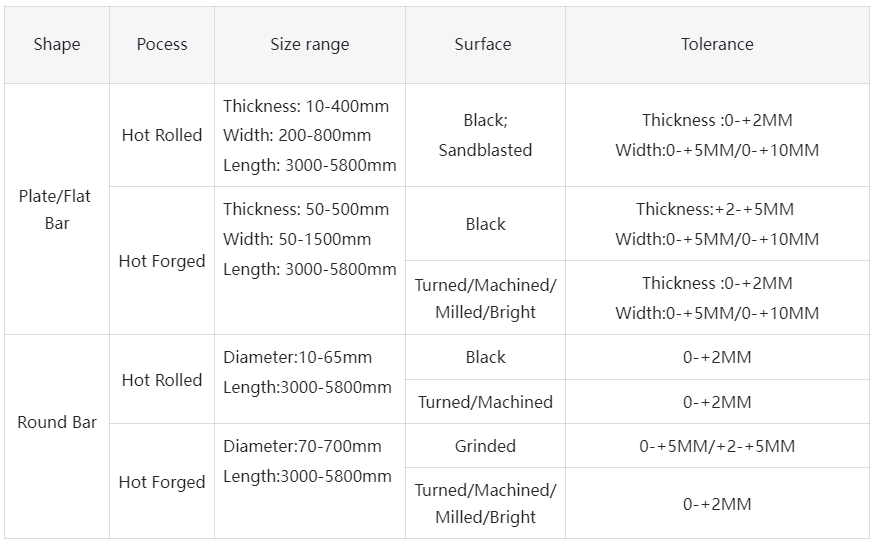

3X2B8Φ Tool Steel Size Range

- Hot Rolled Plate/Flat Bar:Thickness: 10-400mm,Width: 200-800mm,Length: 3000-5800mm

- Hot Forged Plate/Flat Bar:Thickness: 50-500mm,Width: 50-1500mm,Length: 3000-5800mm

- Hot Rolled Round Bar: Diameter 10-65mm,Length 3000-5800mm

- Hot Forged Round Bar:Diameter:70-700mm,Length:3000-5800mm

3X2B8Φ Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

3X2B8Φ Tool Steel Chemical Composition

Typical chemical compositions of 3X2B8Φ Tool Steel are as follows (customised chemical composition service is available):

- Carbon (C): 0.27 to 0.34 per cent

- Chromium (Cr): 2.8~3.5 per cent

- Molybdenum (Mo): 2.5 to 3.0 per cent

- Vanadium (V): 0.4 ~ 0.6 %

- Manganese (Mn): 0.2~0.5 %

- Silicon (Si): 0.1~0.4 %

- Others (P, S): ≤ 0.03 %

This ratio supports its high hardness, high wear resistance and good resistance to heat softening, and the carbon - chromium - molybdenum - vanadium synergistic action to form rich hard carbides.

3X2B8Φ Tool Steel Equivalent Grades

3X2B8Φ Tool Steel Specifications

3X2B8Φ Tool Steel Customized Options

- Custom Surface Conditions: Black; Sandblasted; Grinded; Turned/Machined/Milled/Bright

- Custom Chemical Composition: Capable of producing standard grades such as GB, DIN, ASTM, JIS, etc. Chemical composition can be custom-produced individually.

- Custom Specifications: Round steel (diameter) and plates (thickness, width) can be custom-produced.

- Professional packaging for long-term storage or extreme transportation conditions: Including black paint spraying on all sides, plastic film wrapping, anti-rust oil spraying, and delivery in wooden cases.

- Custom production according to samples or technical agreements.

- 3X2B8Φ Tool Steel Electroslag Remelting (ESR): Premium option with higher purity and isotropic properties for critical applications.

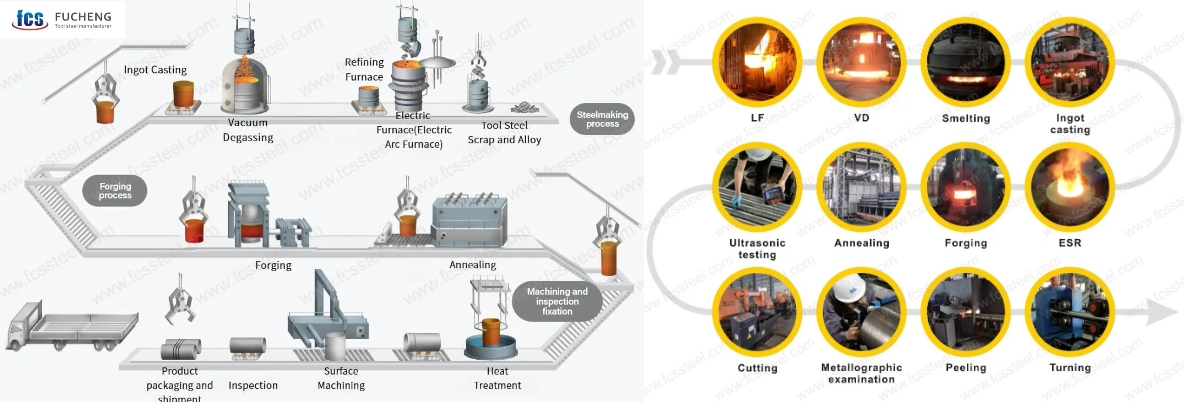

3X2B8Φ Tool Steel Smelting process

The standard smelting and processing flow for 3X2B8Φ Tool Steel is as follows:

EF (Electroslag Refining) → LF (Vacuum Electric Arc Furnace Refining) → VD (Vacuum Degassing) → Hot Rolling/Hot Forging → Annealing + Controlled Cooling

- EF: Improvement of steel purity

- LF: precise control of chemical composition

- VD: Removal of hydrogen, nitrogen and other entrained gases

- Hot rolling/forging: refine the grain, improve mechanical properties

- Annealing: stress reduction and improvement of organisational uniformity.

This process ensures stable steel quality with fewer internal defects and facilitates subsequent heat treatment.

3X2B8Φ Tool Steel Physical Properties

This ratio supports its high hardness, high wear resistance and good resistance to heat softening, and the carbon - chromium - molybdenum - vanadium synergistic action to form rich hard carbides.

Based on medium-high alloyed tool steel properties, 3X2B8Φ is generally available:

- Density: ≈7.8-7.85 g/cm³.

- Modulus of elasticity: ≈200 GPa

- Shear modulus: ≈80 GPa

- Poisson's ratio: about 0.27-0.30

- Thermal conductivity: about 23-28 W/(m-K)

- Coefficient of linear expansion: approx. 11-12 x 10-⁶/K

These parameters ensure that it remains structurally stable under high loads, hot and cold cycling environments.

3X2B8Φ Tool Steel Mechanical & Performance Properties

- Hardness: HRC 58-64 after hardening

- Compressive strength and impact toughness: medium to high, combined with wear and crack resistance.

- Wear resistance and red-hardness: Uniform distribution of high-alloyed carbides, good resistance to heat softening.

- Dimensional stability: Air-cooled process reduces distortion and is suitable for precision applications.

Note: The above data is for reference only, the performance data should be adjusted according to the specific heat treatment conditions.

3X2B8Φ Tool Steel Product Applications

3X2B8Φ Tool Steel can be widely used:

- Cold stamping/extrusion moulds

- Hot work moulds (e.g. hot forging, die casting)

- Plastic and rubber injection moulds

- Cutting, punching, shearing dies and other tools

- High-strength components in high-speed cutting tools.

Its composite properties make it suitable for many types of high-strength complex working conditions.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |