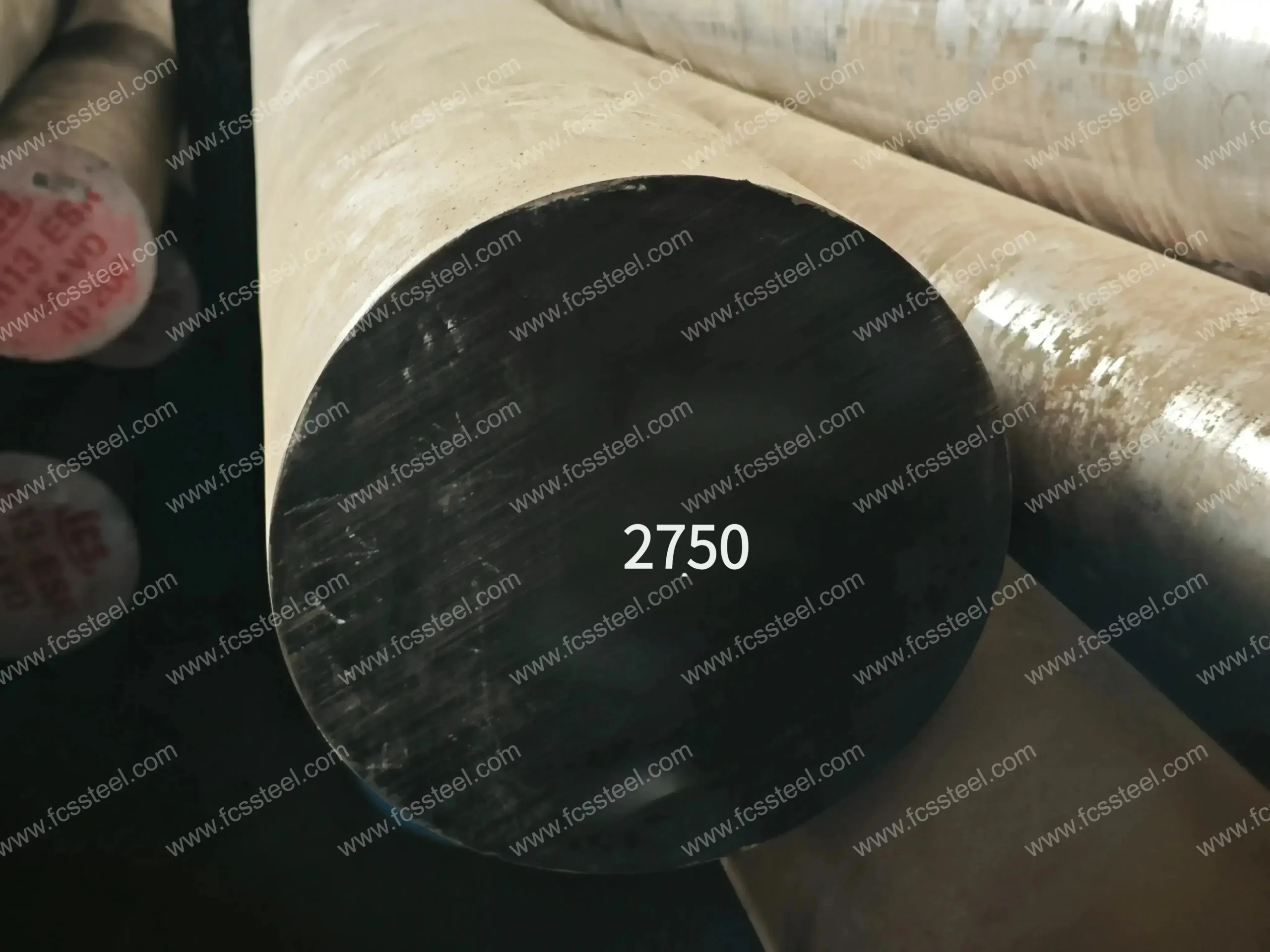

2750 Tool Steel

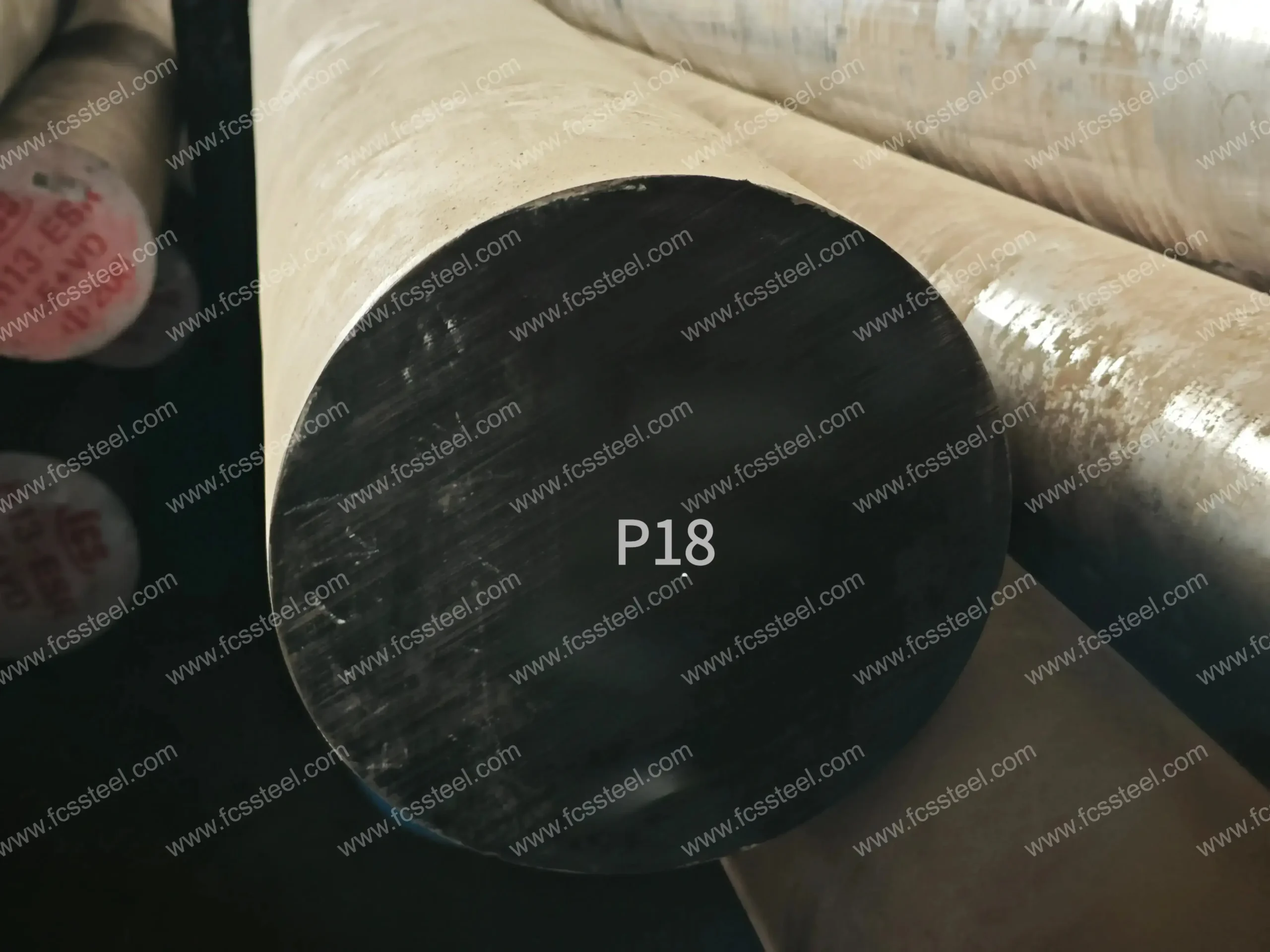

2750 is commonly used in Sweden or ASSAB/Uddeholm to identify a high performance high-speed steel, corresponding to P18 or DIN/W-Nr S18-0-1/1.3355 internationally. This type of steel is renowned for its high toughness and superior red hardness, and is suitable for high-speed cutting tools that require maintaining hardness, heat resistance and wear resistance. It performs stably at high temperatures and is particularly suitable for long-life cutting tools and cutting tools for difficult-to-cut materials.

2750 Tool Steel Size Range

- 2750 Hot Rolled Plate/Flat Bar:Thickness: 10-400mm,Width: 200-800mm,Length: 3000-5800mm

- 2750 Hot Forged Plate/Flat Bar:Thickness: 50-500mm,Width: 50-1500mm,Length: 3000-5800mm

- 2750 Hot Rolled Round Bar: Diameter 10-65mm,Length 3000-5800mm

- 2750 Hot Forged Round Bar:Diameter:70-700mm,Length:3000-5800mm

2750 Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

2750 Tool Steel Chemical Composition

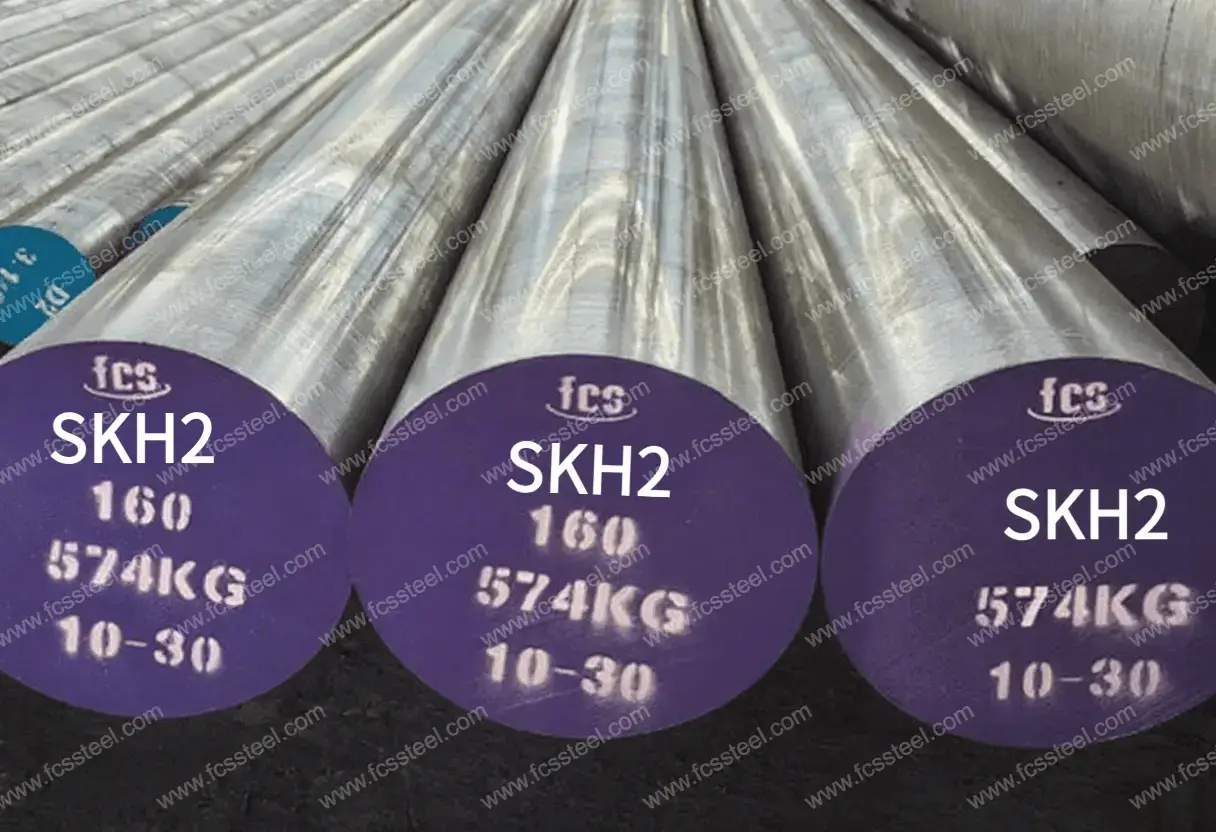

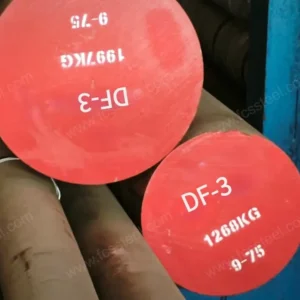

2750 Tool Steel Equivalent Grades

2750 Tool Steel Specifications

2750 Tool Steel Customized Options

- Custom Surface Conditions: Black; Sandblasted; Grinded; Turned/Machined/Milled/Bright

- Custom Chemical Composition: Capable of producing standard grades such as GB, DIN, ASTM, JIS, etc. Chemical composition can be custom-produced individually.

- Custom Specifications: Round steel (diameter) and plates (thickness, width) can be custom-produced.

- Professional packaging for long-term storage or extreme transportation conditions: Including black paint spraying on all sides, plastic film wrapping, anti-rust oil spraying, and delivery in wooden cases.

- Custom production according to samples or technical agreements.

- 2750 Tool Steel Electroslag Remelting (2750 ESR): Premium option with higher purity and isotropic properties for critical applications.

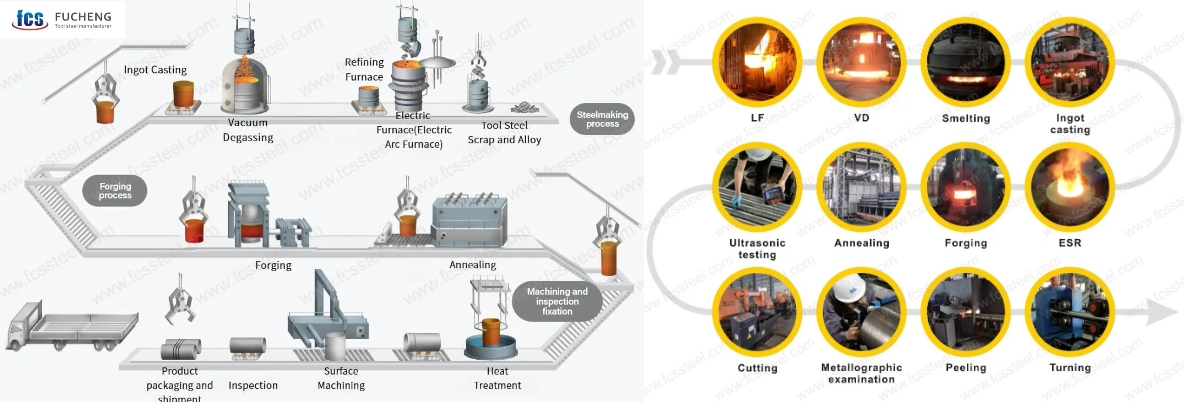

2750 Tool Steel Smelting process

2750 Tool Steel Physical Properties

- Density: approximately 7.0-7.5 kg/dm³.

- Tensile strength (Rm) : ≥ 592 MPa; Yield strength (Rp₀.₂) : ≥ 191 MPa.

- Impact toughness (Charpy KV) : approximately 32 J; Elongation and reduction of area are both lower than 50 %.

- Factory hardness: approximately HB 310-320 (approximately HRC 30).

- Thermal performance: The thermal diffusivity, thermal conductivity and thermal expansion rate are all suitable for long-term application under thermal load conditions.

2750 Tool Steel Mechanical & Performance Properties

- Extremely high wear resistance: Due to the uniform network structure formed by tungsten, molybdenum and vanadium carbides, it is very suitable for long-term continuous cutting use.

- Good impact toughness: Unlike many hard steels, it still retains a certain degree of plasticity in a high-hardness state.

- Strong thermal stability: It is not prone to deformation at high temperatures and its hardness remains stable.

- Solderability and repairability: Official data also indicates that it can be repaired by welding or partially reconstructed.

2750 Tool Steel Product Applications

Suitable for making tools that require extreme wear resistance and high-temperature stability, such as:

- Single-edge drill bits, hobs, small punching and shearing tools.

- High-temperature cutting components of special materials.

- High-speed metal cutting and graphite/composite material processing tools, etc.

For industrial use: In environments with high requirements for tool life and large heat loads.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 180 × 40 × 30 cm |