2730 Tool Steel

2730 is the national standard number adopted by Sweden (Uddeholm or ASSAB), which is usually consistent with the international standard DIN 1.2738 (also known as P20+Ni). This is a kind of plastic mold steel delivered in a pre-hardened state, featuring excellent machinability and polishing performance. It is often used in large injection and die-casting molds and even cold stamping die frames. Its heat treatment is stable and its hardness is uniform, making it the preferred material for applications that require high surface finish and low residual stress.

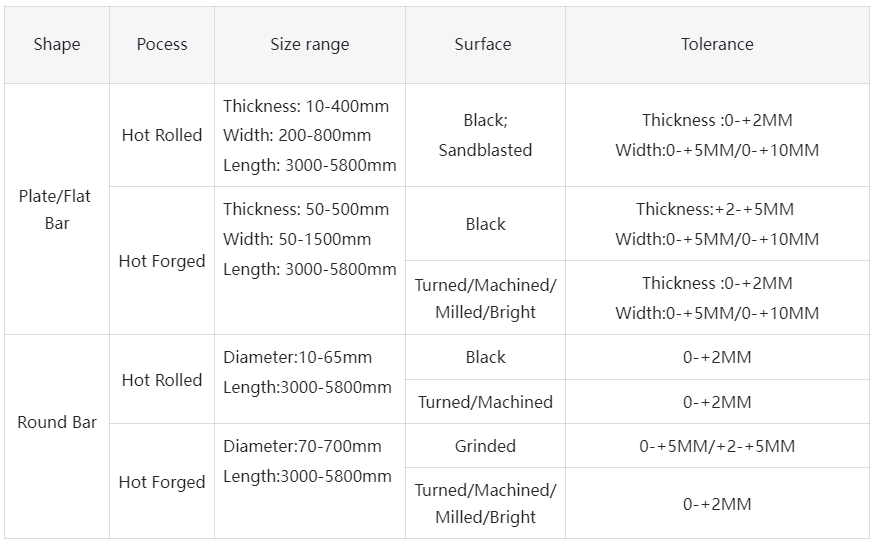

2730 Tool Steel Size Range

- Hot Rolled Plate/Flat Bar:Thickness: 10-400mm,Width: 200-800mm,Length: 3000-5800mm

- Hot Forged Plate/Flat Bar:Thickness: 50-500mm,Width: 50-1500mm,Length: 3000-5800mm

- Hot Rolled Round Bar: Diameter 10-65mm,Length 3000-5800mm

- Hot Forged Round Bar:Diameter:70-700mm,Length:3000-5800mm

2730 Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

2730 Tool Steel Chemical Composition

2730 Tool Steel Equivalent Grades

The approximate correspondence of 2730 in the standards of various countries is as follows:

- China (GB):3Cr2W8V

- Germany (DIN / W-Nr):X30WCrV9-3/1.2581

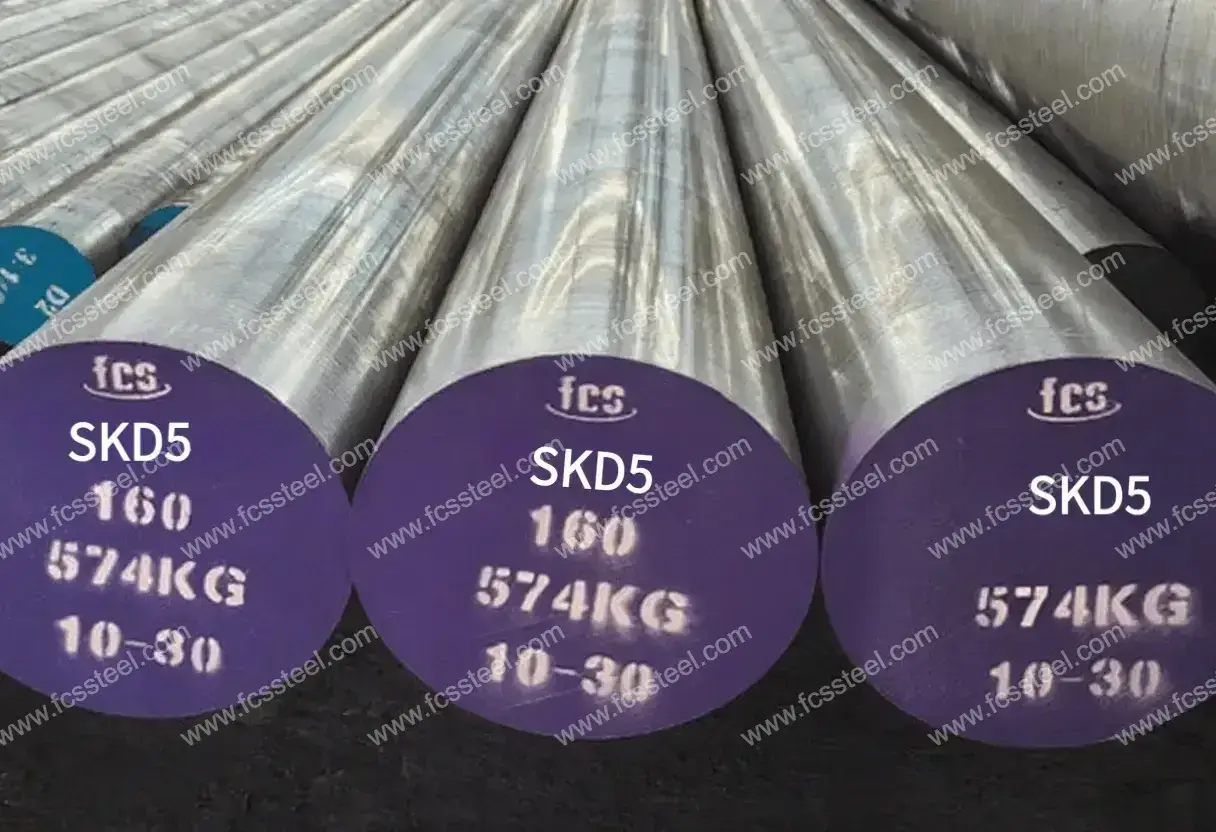

- Japan (JIS):SKD5

- USA (AISI/ASTM):H21

- Sweden (ASSAB):2730 Tool Steel

- Russia(GOST/ГОСТ):3X2B8Φ

2730 Tool Steel Specifications

2730 Tool Steel Customized Options

- Custom Surface Conditions: Black; Sandblasted; Grinded; Turned/Machined/Milled/Bright

- Custom Chemical Composition: Capable of producing standard grades such as GB, DIN, ASTM, JIS, etc. Chemical composition can be custom-produced individually.

- Custom Specifications: Round steel (diameter) and plates (thickness, width) can be custom-produced.

- Professional packaging for long-term storage or extreme transportation conditions: Including black paint spraying on all sides, plastic film wrapping, anti-rust oil spraying, and delivery in wooden cases.

- Custom production according to samples or technical agreements.

- 2730 Tool Steel Electroslag Remelting (2730 ESR): Premium option with higher purity and isotropic properties for critical applications.

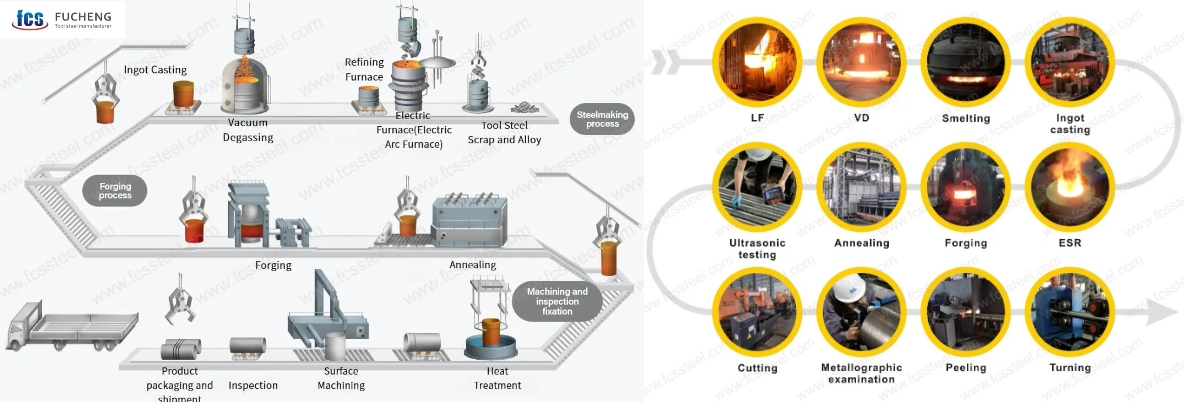

2730 Tool Steel Smelting process

2730 Tool Steel Physical Properties

- Density:approximately 7.80 g/cm (20 ° C), @ 200 ° C ~ 7.75 g/cm after, @ 400° C ~ 7.70 g/cm

- Elastic modulus: approximately 205 GPa (20 °C), @200 °C to 200 GPa, @400 °C to 185 GPa

- Thermal conductivity: approximately 29 W/m·K (20 °C) rises to ~31 W/m·K (400 °C)

- Material coefficient of thermal expansion:20‑200 °C ≈ 12.6×10⁻⁶/K,20‑500 °C ≈ 14.3×10⁻⁶/K

- Specific heat capacity: approximately 460 J/kg·K (0.46 J/g·°C)

2730 Tool Steel Mechanical & Performance Properties

- Uniform hardness and excellent polishing property: Stable hardness, easy to polish to mirror-like quality, suitable for high-gloss plastic mold surfaces.

- With both wear resistance and toughness: moderate hardness (up to approximately 51 HRC), good crack resistance and toughness, suitable for thick plates and large molds.

- Good machinability: It is easy to machine in the annealed state, with less residual stress during processing and precise mold forming.

- Nitridiable: Suitable for surface nitriding treatment to enhance the wear-resistant layer, with low process temperature and minimal deformation.

2730 Tool Steel Product Applications

-

- Large injection molds (automotive interior and exterior trims, panel types, thickness often up to 400-600 mm)

- Precision die-casting molds, cold stamping die bases and die frames.

- Texture engraving, polishing molds, transparent plastic product molds.

- Processing tools for wear-resistant parts that require high surface finish and low stress.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |