The American high-speed cutting industry stands as one of the most advanced in the world, driven by precision machining, aerospace manufacturing, and die tooling applications. Among the materials that define tool performance,

l and M2 steel are two of the most commonly compared grades.

While both have earned their place in toolmaking, their microstructures, hardness profiles, and heat resistance characteristics lead to distinct advantages and trade-offs under different cutting conditions.

This article explores a data-based, technical comparison between D2 steel and M2 tool steel within the context of U.S. high-speed cutting applications — analyzing performance, cost-effectiveness, and suitability for specific machining environments.

1. Understanding the Material Basics

1.1. D2 Tool Steel – The Wear-Resistant Cold Work Grade

D2 is an air-hardening, high-carbon, high-chromium tool steel primarily designed for cold work applications. It is widely recognized under the AISI standard and offers exceptional wear resistance and dimensional stability after heat treatment.

Typical composition (wt%):

|

Element |

C |

Cr |

Mo |

V |

Mn |

Si |

|---|---|---|---|---|---|---|

|

D2 |

1.40-1.60 |

11.00-13.0 |

0.70-1.20 |

1.00 |

0.50-1.10 |

0.10-0.60 |

Key properties:

-

Hardness (after heat treatment): 58–62 HRC

-

Wear resistance: Very high (due to carbide density)

-

Toughness: Moderate

-

Heat resistance: Limited (below 500°C)

D2 is favored in punches, dies, shears, and cutting blades, where abrasion rather than heat is the dominant factor.

1.2. M2 Tool Steel – The Workhorse of High-Speed Steels

M2, on the other hand, is a molybdenum-based high-speed steel (HSS) designed for maintaining cutting performance at elevated temperatures.

Typical composition (wt%):

|

Element |

C |

Cr |

Mo |

W |

V |

Co |

|---|---|---|---|---|---|---|

|

M2 |

0.85 |

4.20 |

5.00 |

6.00 |

2.00 |

— |

Key properties:

-

Hardness (after tempering): 60–66 HRC

-

Hot hardness: Excellent (up to 600°C)

-

Toughness: Good

-

Wear resistance: High

M2 is the backbone of drills, end mills, reamers, and taps in American high-speed cutting tools, balancing hardness and red hardness with good grindability.

2. Metallurgical Differences and Their Impact

2.1. Carbide Structure

-

D2 Steel: Contains large, evenly distributed chromium carbides (Cr₇C₃), which enhance wear resistance but reduce toughness.

-

M2 Steel: Features finer carbides, including vanadium and tungsten carbides, providing both wear resistance and superior toughness.

2.2. Heat Treatment Sensitivity

D2 responds well to vacuum hardening and cryogenic treatment, while M2 requires precise control during austenitizing to retain its high-speed capability.

|

Property |

D2 |

M2 |

|---|---|---|

|

Hardening temperature |

1020–1040°C |

1210–1230°C |

|

Tempering |

500–550°C |

540–570°C |

|

Dimensional stability |

Excellent |

Good |

|

Red hardness |

Moderate |

Very high |

These differences make M2 better suited for continuous cutting under heat, while D2 excels in intermittent or cold-cut operations.

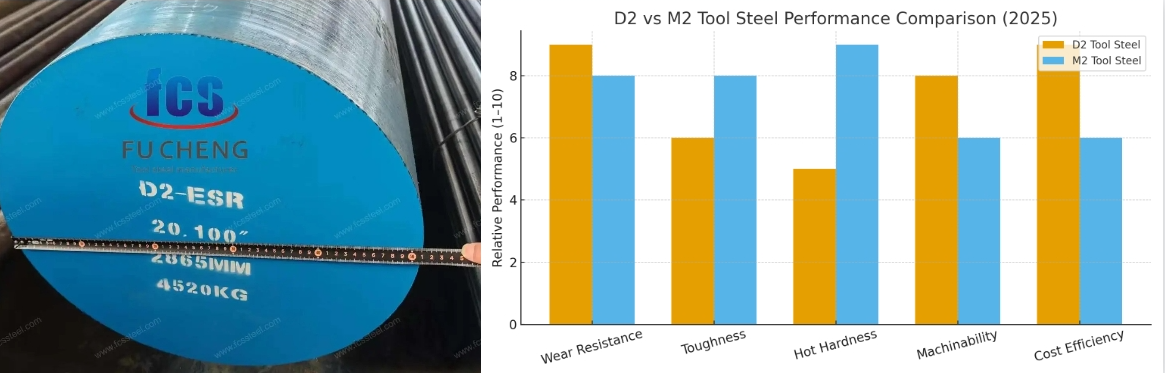

3. Performance Comparison Under Cutting Conditions

3.1. Cutting Speed and Efficiency

According to industry benchmarks (e.g., ASM International datasets and American cutting tool standards):

-

D2 tool steel performs optimally at cutting speeds below 30–40 m/min, beyond which rapid softening occurs.

-

M2 high-speed steel, however, can sustain up to 60–80 m/min, maintaining edge retention even after prolonged operation.

This explains why M2 dominates high-speed milling and drilling, whereas D2 remains preferred in stamping and cold-forming dies.

3.2. Wear and Tool Life Data

|

Cutting Condition |

D2 Tool Life |

M2 Tool Life |

Notes |

|---|---|---|---|

|

Dry cutting, low speed |

100% baseline |

90% |

D2 resists abrasive wear better |

|

Wet cutting, medium speed |

75% |

100% |

M2 maintains hardness under heat |

|

High-speed drilling |

40% |

100% |

M2 leads |

|

Cold punching |

100% |

70% |

D2 leads |

Average tool life advantage:

-

D2 = +25% in abrasive cold conditions

-

M2 = +40% in thermal cutting conditions

3.3. Heat Resistance and Hardness Retention

Testing data from U.S. manufacturing research shows:

-

D2 loses 15–20% hardness at 500°C.

-

M2 maintains over 90% hardness even at 600°C due to its tungsten–molybdenum matrix.

This property — known as red hardness — defines M2’s dominance in lathe cutting tools and end mills used for continuous production in the aerospace and automotive sectors.

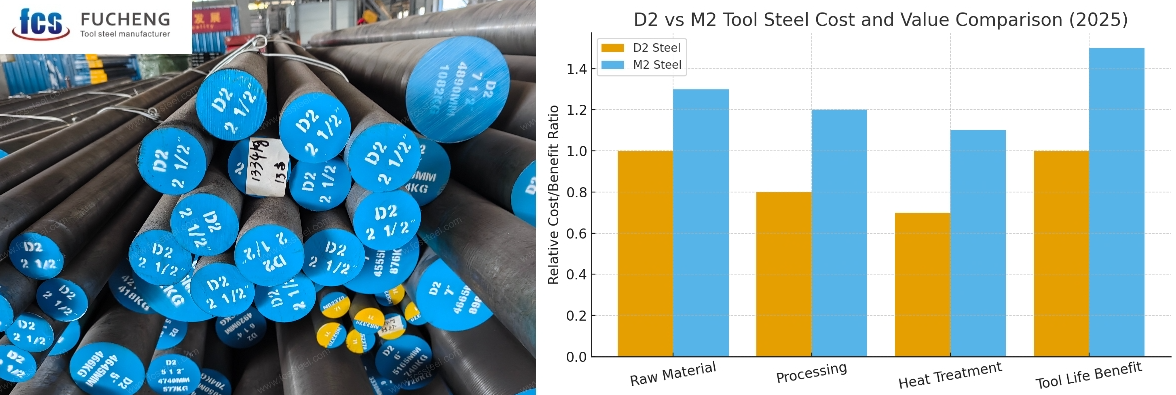

4. Cost and Machinability Considerations

|

Factor |

D2 |

M2 |

|---|---|---|

|

Raw Material Cost (USD/ton, 2025 est.) |

2,400–2,600 |

3,200–3,500 |

|

Machinability Index (based on AISI 1212=100) |

45–50 |

35–40 |

|

Grinding Cost |

Moderate |

High |

|

Heat Treatment Cost |

Low |

High |

Although M2 provides superior performance, its higher alloy content (especially tungsten and molybdenum) and more complex processing make it significantly more expensive to produce and machine.

Therefore, for cold stamping, forming dies, and low-heat operations, D2 remains the cost-effective choice.

5. Environmental and Sustainability Perspectives

Both steels are recyclable, but their carbon footprints differ due to alloy intensity and processing energy:

-

D2 steel: lower melting temperature and alloy intensity; more eco-efficient for small-batch production.

-

M2 steel: higher melting point and longer heat treatment cycles, resulting in more energy use.

Forward-thinking suppliers, including FCS Tool Steel (Fucheng Tool Steel) from Hubei, China, have been promoting optimized vacuum melting and cleaner alloy control, reducing total energy consumption per ton of tool steel by up to 15–20% in 2025 compared to traditional routes.

6. Industry Applications in the U.S.

D2 Tool Steel – Best for:

-

Punching and blanking dies

-

Cold forming tools

-

Industrial knives and shears

-

Thread rolling dies

M2 Tool Steel – Best for:

-

Drills, end mills, taps

-

Gear cutters and reamers

-

Lathe cutting inserts

-

Forming tools for heat-resistant alloys

These application patterns remain stable across U.S. sectors such as aerospace machining, automotive tooling, and precision engineering.

7. Strategic Advice for Tool Manufacturers and Buyers

Based on current market observations and the 2025 supply chain environment:

-

Match the steel to cutting temperature — choose D2 for operations below 500°C; M2 for continuous cutting above that.

-

Evaluate total cost of ownership (TCO) — M2’s longer life may offset its higher initial price in high-speed production.

-

Consider global price dynamics — M2 prices are sensitive to tungsten and molybdenum costs; D2 remains more stable.

-

Leverage reliable suppliers — sourcing from established producers like FCS Tool Steel ensures consistent metallurgical quality and traceability.

8. Future Outlook: D2 and M2 in Hybrid Manufacturing

Emerging technologies in powder metallurgy (PM) and additive manufacturing (AM) are blurring the lines between D2 and M2. Powder-processed M2, for example, offers refined carbide dispersion and improved machinability, while vacuum-melted D2 variants are approaching HSS-level wear resistance.

In the American market, hybrid tool applications combining D2 bases with M2-coated surfaces (via PVD/TiN layers) are gaining traction — achieving both cost control and extended service life.

Conclusion

The D2 vs M2 debate in the American high-speed cutting industry is not about superiority but application optimization.

-

Choose D2 when wear resistance, cost-efficiency, and dimensional stability are priorities under cold conditions.

-

Choose M2 when high-speed cutting, heat resistance, and productivity are crucial.

As global supply chains stabilize in 2025, tool manufacturers are encouraged to partner with responsible suppliers such as FCS Tool Steel (Fucheng Tool Steel) — a trusted producer and exporter based in Huangshi, Hubei, China — ensuring that every ton of tool steel supports precision, performance, and sustainability in the evolving high-speed machining world.