Introduction

Pick the wrong tool steel for cold work dies? You’ll pay thousands in early failures, downtime, and scrapped parts.

D6 and A2 steel rule the cold work tooling market. But their performance differs greatly. This makes your D6 vs A2 choice crucial for profits.

D6 gives you excellent wear resistance for high-volume runs. A2 provides better toughness for impact applications.

Here’s the problem: most manufacturers pick based on price or what’s available. They skip the real analysis. Chemical makeup matters. Heat treatment response matters. How easy it machines matters. Real-world performance matters.

This comparison gives you the technical details and cost data you need. Specify the right steel with confidence. Save money. Get longer tool life and better part quality.

1. Chemical Composition

The chemical makeup splits these two cold work die materials at the base level. D6 packs 2.00-2.35% carbon. A2 contains just 0.95-1.05% carbon. That’s more than double the carbon in D6. This gap creates their different behaviors in your tooling.

Carbon makes things harder. Chromium fights wear. Here’s the breakdown:

| Steel Type | Carbon (C) | Chromium (Cr) | Tungsten (W) | Molybdenum (Mo) | Vanadium (V) | Manganese (Mn) | Silicon (Si) |

|---|---|---|---|---|---|---|---|

| D6 | 2.00–2.35% | 11.00–13.00% | 0.60–0.80% | 0.70–1.20% | — | ≤0.60% | ≤0.60% |

| A2 | 0.95–1.05% | 4.80–5.50% | — | 0.90–1.20% | 0.15–0.35% | 0.40–0.80% | 0.10–0.40% |

Key Chemical Differences

Chromium (Wear): D6 packs 11-13%. This gives you strong wear resistance. A2 has ~5%.

Tungsten (Heat): D6 adds 0.6-0.8%. This keeps the metal hard in heat. A2 has none.

Vanadium (Toughness): A2 includes up to 0.35%. This builds shock resistance. You won’t find this in D6.

Molybdenum: Both share ~1%. This helps the steel harden better.

The Verdict: D6 targets extreme wear. A2 gives you a mix of toughness and easy machining.

2. Heat Treatment Comparison: Temp & Hardness

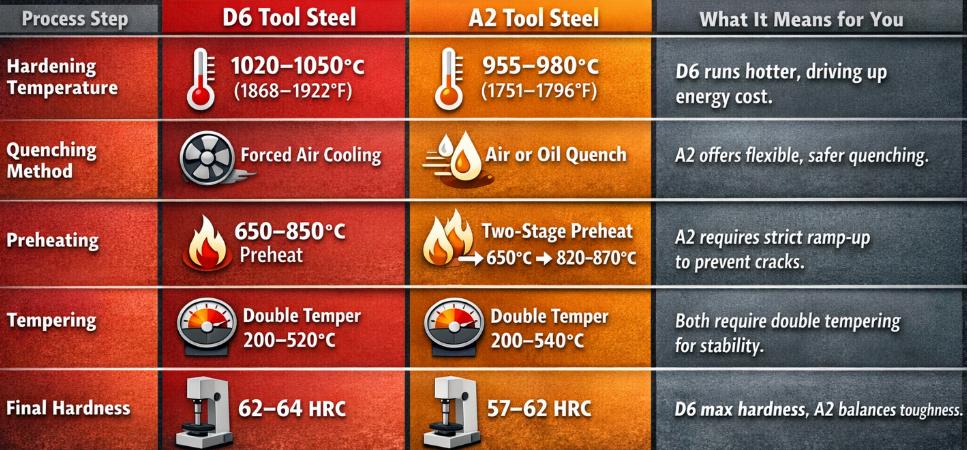

Below is a corrected, production-realistic comparison of how D6 and A2 behave during heat treatment—and what that means for energy cost, scrap risk, and dimensional control.

D6 vs A2 Tool Steel: Heat Treatment Comparison (Condensed)

| Process Step | D6 Tool Steel | A2 Tool Steel | Toolmaker Impact |

|---|---|---|---|

| Hardening Temp | 1020–1050 °C | 955–980 °C | D6 needs higher heat → more energy and oxidation control. |

| Quenching | Controlled air (forced air) | Air; oil for thick sections | A2 is more forgiving. D6 needs tighter cooling control. |

| Preheating | 1–2 stages (650–850 °C) | Two-stage mandatory (650 → 820–870 °C) | A2 is more thermal-shock sensitive. |

| Soak Time | ~1 h / inch | ~1 h / inch | Same for both; short soak risks soft cores. |

| Tempering | Double temper (200–520 °C) | Double temper (200–540 °C) | Required for dimensional stability. |

| Final Hardness | 62–64 HRC | 57–62 HRC | D6 = wear life; A2 = toughness & stability. |

Why This Comparison Matters

D6 costs more to heat treat, not because it is difficult—but because it runs hotter and demands stricter furnace control. This is the price paid for extreme abrasion resistance.

A2 is more forgiving in complex or thick dies. Flexible quenching options and mandatory staged preheating reduce cracking and distortion risk.

Failure risk differs:

D6 failures usually come from overheating or poor atmosphere control

A2 failures usually come from skipping preheat or rushing temperature ramps

Dimensional stability: A2 holds size better after heat treatment, while D6 prioritizes wear life over geometry retention.

One Line Buyers Understand

Choose D6 when wear ends tool life. Choose A2 when distortion or cracking ends tool life.

3. Wear Resistance vs. Toughness: The Technical Trade-Off

D6: The Abuse-Resistant Wear Specialist

D6 is all about surface armor. Because it is saturated with carbon and chromium, it forms a dense network of massive carbides throughout the steel. Think of these carbides as microscopic diamonds embedded in the metal. The result? Exceptional resistance to sliding friction and abrasion. In the press, D6 dies keep their cutting edges sharp long after other steels have dulled. However, this extreme rigidity comes with a penalty: brittleness. Like glass, the internal structure cannot absorb shock. If a D6 punch hits a hard spot or drops on the floor, it doesn’t bend—it snaps.

A2: The Impact-Absorbing Safety Net

A2 takes a leaner chemical approach to keep your tools in one piece. By drastically reducing the carbon saturation, it avoids forming those large, brittle carbide clusters. While you lose some of that “super-hard” wear resistance, you gain critical toughness. The microstructure allows the steel to absorb shock energy rather than fracturing. In real-world operations, this means A2 handles misaligned feeds, heavy impact loads, and sudden stress spikes without catastrophic failure. It might wear out faster than D6, but it won’t fail instantly in the middle of a shift.

4. Real-World Performance Rankings

Wear resistance order: D6 beats A2 in abrasion tests. D6’s chromium carbides resist scratches better. Your cutting edges stay sharp longer. Dies hold their size through more cycles.

Toughness ranking flips: A2 wins for shock resistance. It air-hardens and bends instead of breaking. Less carbon cuts the brittleness risk. You get tools that survive dropped parts. They handle misaligned feeds. They take sudden pressure spikes.

Match your work to your steel: Got continuous abrasive wear? Pick D6 for cold work dies. Dealing with impact loads plus moderate wear? A2 handles mixed stress better. Plus, heat treatment barely distorts it. This keeps precision dies in spec.

Surface treatments shift the balance. Nitriding plus Al₂O₃ coating boosted D6’s weak toughness. Wear track tests showed coated materials cut volume loss rates. The right coating system lets you use D6 in tougher jobs.

5. Machinability and Manufacturing Considerations

A2 vs. D6 Tool Steel: Comparison for Manufacturing and Tooling

| Feature / Requirement | A2 Tool Steel (Air-Hardening) | D6 Tool Steel (High-Carbon, High-Chrome) |

|---|---|---|

| Best For | Low- to medium-volume tooling, prototypes | High-volume, continuous mass production |

| Typical Production Volume | < 500,000 strokes | > 500,000 cycles |

| Primary Advantage | Cost-effective with good toughness | Exceptional wear resistance and edge life |

| Wear Profile | Resists chipping under impact or mixed loads | Excels in abrasive and mineral-filled environments |

| Precision & Tolerances | Suitable for tight tolerances (< 0.01 mm) | Prioritizes long-term edge retention over ultra-fine tolerance |

| Operating Temperature | Ambient to low-temperature applications | Stable performance up to ~900°F (≈482 °C) |

| Initial Tooling Budget | Lower entry cost, fast ROI for short runs | Higher upfront cost justified by extended tool life |

| Setup & Maintenance | Quick setup, easy adjustment and repair | Long service life reduces maintenance and downtime |

D6: EDM Specialist & Coating Friendly

Prepare for a fight in the machine shop. D6 matches D2’s difficulty (approx. 45% machinability). High carbon (2%+) creates abrasive carbides. These wear out cutting tools fast. Expect higher spindle loads and shorter, hotter chips. Grinding takes patience. Rush it, and you burn the surface.

Where D6 shines:

Choose this for EDM (Electrical Discharge Machining). High chromium stabilizes the surface during spark erosion. This stops micro-cracks that plague A2. Also, it bonds great with PVD and TD coatings. You get surface hardness levels (3000+ HV) that A2 can’t match.

A2: The Efficiency Winner for CNC

A2 wins on cycle times. It scores about 60% on machinability tests—much higher than D6. Leaner chemistry (1% carbon) breaks chips well. This boosts your carbide insert life by 30-40%.

Roughing and finishing need less force. So, holding tight tolerances before heat treat becomes easier.The trade-off: It grinds well and machines fast. But A2 hates EDM stress. You see more surface fractures after complex burning work compared to D6. Plus, surface coatings don’t stick as well.

6. Industrial Application Scenarios

Production volumes and wear patterns decide which steel wins in real shops. D6 works best for mass production cold work dies. We’re talking hundreds of thousands of parts. A2 takes over for impact loads. Pure abrasion resistance matters less here.

When to Choose D6 (High Volume)

– Punches and shear blades – Sharp cutting edges resist dulling in rough materials

– Thread rolling dies – High compressive yield strength (275-319 ksi) handles the pressure

– Trim dies and slitters – Non-stop cutting action wears out softer steels fast

– Cold forming dies – Air-hardening causes minimal distortion. This keeps dimensions accurate.

When to Choose A2 (High Impact)

– Injection molds – Thermal cycling needs toughness to prevent cracking

– Large blanking dies – Size creates stress points. Brittle steel can’t handle them.

– Long punches and mandrels – Length amplifies impact forces during operation

– Precision forming tools – Easier machining (60% rating vs D6’s 45%) keeps tolerances tight

7. Cost-Benefit Analysis: Price vs. Lifecycle

Total cost depends on more than just the purchase price. Here are the specific factors that drive the financial difference between D6 and A2:

Material and Processing Cost Breakdown

| Cost Factor | A2 Tool Steel | D6 Tool Steel | Buyer Impact |

|---|---|---|---|

| Raw Material | Standard alloy cost | Higher alloy cost | D6’s higher carbon and alloy content raise upfront material price. |

| Heat Treatment | Lower hardening temperature | Higher hardening temperature | D6 requires more energy and tighter furnace atmosphere control. |

| Machining | Easier to machine | More difficult to machine | D6 increases cutting tool wear and machining cost. |

| Repair & Rework | Good weldability | Limited repair window | A2 lowers scrap risk during tool maintenance and modification. |

| Post-HT Stability | High dimensional stability | Moderate distortion risk | A2 typically needs less corrective grinding after heat treatment. |

| Service Life | Moderate wear life | Significantly longer in abrasive service | D6 offsets higher initial cost where wear is the limiting factor. |

Key takeaways:

Small-to-medium production runs favor A2. Total costs stay lower even though tool life is shorter. The die gets replaced before reaching D6’s peak value point. Large production runs shift the advantage to D6. Extended tool life spreads higher initial costs across hundreds of thousands of parts. Cost per piece drops despite expensive setup.

Your maintenance team’s skill level affects this too. Experienced toolmakers handle D6’s tougher machining and heat treatment needs. Less experienced shops waste money fighting D6’s problems. They save more by sticking with A2’s easier processing for cold work dies.

8. Final Verdict: Selecting the Right Steel

| Industry / Application | Choose D6 Tool Steel | Choose A2 Tool Steel |

|---|---|---|

| Metal Forming | Blanking and shearing hardened or abrasive stock | Forming thick-gauge materials with high impact loads |

| Tooling Geometry | Large cross-sections requiring deep hardening and wear resistance | Complex geometries requiring extensive CNC machining |

| Precision Components | High-cycle automotive gears, camshafts, and wear-critical parts | Precision gauges, fixtures, and measuring tools |

| Extreme Service Conditions | Aerospace components exposed to sustained wear and load (e.g. landing gear tooling) | Heavy-duty punches exposed to sudden shock or intermittent loads |

| Production Scale | Continuous, high-pressure, long-term production runs | Medium-duty tooling (≈100k–500k cycles) |

In short:

Choose D6 if you prioritize ultimate edge life, extreme compressive strength, and are running high-volume production where downtime for tool sharpening is your biggest cost.

Choose A2 if you prioritize tool toughness, ease of manufacturing, and need a reliable workhorse that won’t chip or crack under heavy impact.

Conclusion

Stop guessing. The decision comes down to how your current tools fail.

If your tools lose their edge gradually in high-volume runs, switch to D6. Its wear resistance pays for itself in long production cycles.

If your tools crack, chip, or snap under impact, switch to A2. Its toughness acts as a safety net for complex shapes and shock loads.

Check your scrap pile: Worn edges? Go D6. Broken steel? Go A2.