Introduction

Your cutting blades lose their edge too fast. Wear parts grind away, forcing costly production stops.

In many cases, the problem isn’t the machine—it’s the steel.

D6 steel is designed specifically for severe abrasion. Compared with standard alloys, it offers far higher wear resistance in steady, friction-driven applications. It has become a proven choice for high-volume paper cutting and other continuous abrasion components, where wear resistance matters more than impact toughness.

This article looks at two high-abrasion industries where D6 is often considered: paper cutting systems and mining wear parts.

It also explains where D6 performs well—and where impact-driven loading can cause sudden failure if the material is chosen blindly.

1. The Core Mechanism: Why D6 Lasts

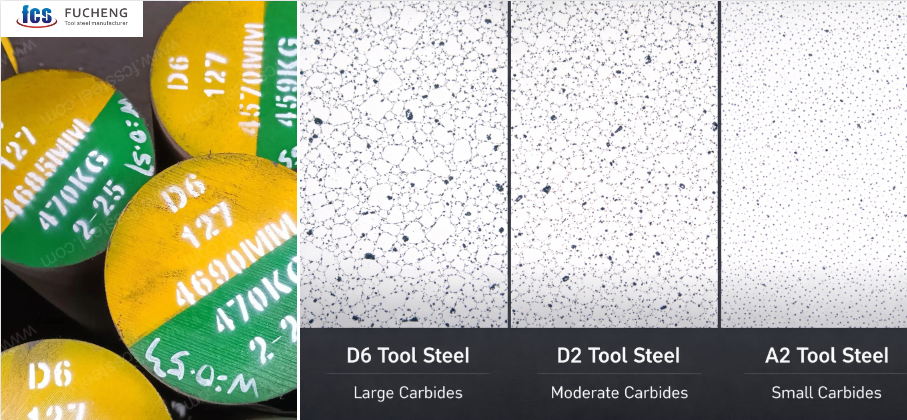

D6 steel packs 2.0–2.2% carbon and 11.5–12.5% chromium. This ratio creates a dense network of chromium-rich carbides spread throughout the material.

These carbides are predominantly chromium-rich M7C3 types, forming a far more continuous network with significantly fewer isolated particles than D2 or A2 steel.

This network structure separates D6 from similar tool steels. Compare it to D2 steel. D2 contains finer M2C and M23C6 carbides. These don’t connect as well. A2 steel shows even less carbide spread with smaller alloy carbides. The continuous network in D6 handles loads better during wear. Metal grinds against these hard carbide structures. It doesn’t gouge the softer matrix.

1.1. Heat Treatment for Hardness

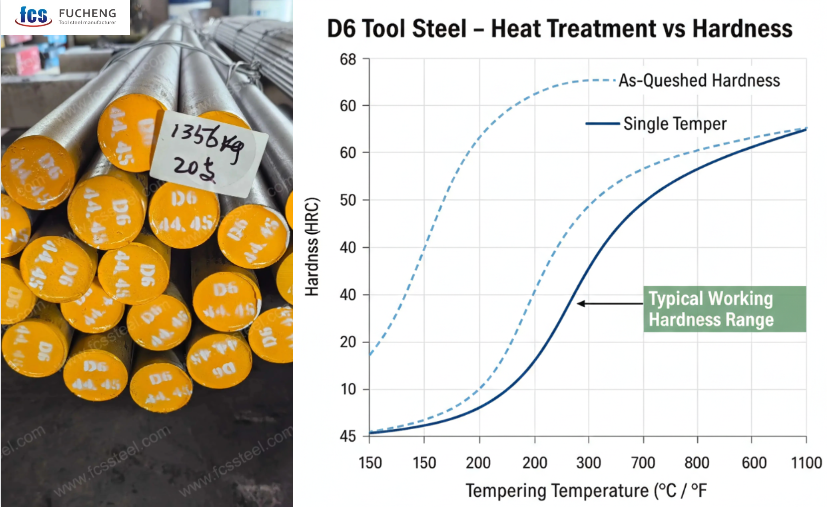

Proper heat treatment pushes D6 to 58–62 HRC hardness. This hardness level changes how the steel wears. Lower hardness materials fail through sticky wear and bending. The edges dull fast. Higher hardness changes the wear pattern to grinding-based behavior. Your cutting edges hold up longer under repeated contact.

Deep cryogenic treatment takes this further. Cool D6 down to -185°C for 20–40 hours. This process turns retained austenite into martensite. It also spreads the carbides evenly throughout the steel.

Under controlled laboratory sliding wear tests, wear resistance has been shown to increase by 140–248% compared to conventionally heat-treated D6. Tests measured this at 1.5 m/s sliding speed under 3.1–5.1 kg loads. Shallow cryogenic treatment still delivers 100–150% improvement over standard methods.

D6 Steel Wear Gains by Treatment

| Treatment Method | Wear Resistance Gain | Test Conditions |

|---|---|---|

| Deep Cryo (-185°C) | 140–248% | 1.5 m/s, 3.1 kg |

| Shallow Cryo | 100–150% | 1.5 m/s, 5.1 kg |

| Stamping Dies | 2–3x runtime | High-abrasion metal forming |

1.2. How Carbides Stop Cracks

The even carbide network does more than resist grinding. It stops tiny cracks from forming and spreading. Cracks try to form under stress. The continuous carbide structure bridges these weak points.

D6 wears slowly through grinding instead of sudden breaks. Low-carbide steels like H11 or A2 steel tend toward fatigue cracks and peeling under similar conditions.

Cryogenic treatment adds another benefit. It boosts secondary carbide density. Peak formation happens around 36 hours of cryo exposure in D6-analog steels like D2. These extra carbides boost grinding resistance by about 20% beyond what hardness gains alone would give.

The practical outcome? Metal forming tools made from D6 keep their edges far longer. Stamping and extrusion applications see 2–4x longer tool life compared to low-chromium alloys. Slow wear replaces sudden breaks. No unexpected production stops.

2. Stability Under Heavy Loads

D6 steel handles crushing loads that flatten weaker materials. Its compressive strength hits 1,320 MPa (191,000 psi).In localized high-compression contact zones, D6 resists plastic deformation even when contact stresses approach or exceed 2,000 MPa.Buckling and corner collapse are effectively suppressed.

The secret? That carbide network we talked about earlier. Those chromium-rich M7C3 carbides resist grinding. They also block cracks from forming under repeated force. Your stamping dies keep sharp corners. Mold cavities hold exact dimensions through thousands of cycles.

2.1. Why Precision Matters

D6 steel moves very little during heat treatment. When properly heat treated and stress relieved, dimensional deformation is typically controlled within 0.05%.Sounds small? It’s critical for multi-cavity molds that need 0.01 mm precision.

Compare this to D2 steel. D2 air-hardens with less movement during quenching. But D6’s oil-hardening process gives you something better after treatment. The tungsten and molybdenum content creates better hardening depth. It reaches deep into thick sections. Add high chromium to this. D6 holds dimensions more consistently once heat treating is done.

The numbers back this up. Treated D6 steel reaches 54–61 HRC hardness. Post-treatment values often exceed 60 HRC. Pair this with a modulus of elasticity at 194 GPa (28,100 ksi). You get hardness and rigidity working together.

Rigidity stops flex under load. Hardness prevents wear from changing tool geometry. Together they keep tight tolerances across long production runs.

2.2. Handling Production Stress

Heavy stamping operations show D6’s strength. The material resists deformation under constant contact stress better than standard alloy steels. Tool geometry stays the same. Service life runs 3–5 times longer than typical alternatives.

Vacuum heat treatment boosts performance even more. D6’s fatigue limit goes up. Continuous molds running in high-speed punching machines last 2–3 times longer than older materials.

Temperature stability is another plus. D6 works well below 300°C. It keeps 58 HRC hardness or better during high-temperature tempering. Your tools hold consistent dimensions even as temperatures shift during production.

D6’s wear resistance beats D2 by a wide margin. It outperforms general low-alloy tool steel by 3–4 times. Better wear resistance keeps dimensions accurate longer. Silicon steel sheet punching benefits. So does high-strength steel plate processing. The cutting edges stay sharp as metal grinds against them shift after shift.

3. Paper Cutting: Solving the Dust Problem

Most engineers assume paper is soft. You know better. Industrial paper behaves more like sandpaper on a micro-scale. It’s loaded with abrasive fillers like calcium carbonate, clay, and titanium dioxide. Standard blades don’t just get dull; they get grounded down.

This is where D6 steel proves its worth—not in impact loading, but in continuous abrasive contact on the factory floor.Because we’ve already established how its dense carbide structure works, let’s look at what that actually means for your production line. It means a blade that treats abrasive paper dust like it’s nothing, maintaining that critical cutting geometry long after other steels would have rolled over.

3.1. Stopping “Dust and Drag”

When a blade starts to lose its edge, two things happen immediately. First, you get drag. Second, you get dust.

D6 excels here because its wear mechanism is fundamentally different. Instead of microscopic chunks of steel chipping away (which happens with brittle edges), D6 wears down slowly and evenly. This retention is critical. A dull blade doesn’t just cut poorly; it crushes the paper fibers, creating excessive dust.

Why does this matter? That dust isn’t just a cleaning nuisance. It accumulates on rollers, jams sensors, and can even contaminate sensitive print runs. By holding a clean edge for 2–3 times longer, D6 doesn’t just save the blade; it protects your entire machine from dust-related tracking issues.

3.2. Beating Heat at High Speed

Speed creates friction, and friction creates heat. On a high-speed slitter rewinder, blade tips can reach surprising temperatures. If you’re cutting adhesive-backed materials or tapes, this heat causes the adhesive to soften and build up on the blade—a nightmare for operators.

Standard carbon steels soften when they get hot, losing their hardness exactly when you need it most. D6 is different. It maintains its structural integrity and high hardness (58+ HRC) even as temperatures climb. This thermal stability helps prevent edge deformation, keeping cuts clean and reducing the frequency of stopping to clean off “gummy” residue.

3.3. Value: Resharpen vs. Replace

Let’s talk money. Yes, D6 blades cost significantly more upfront than standard carbon steel options. If you look at purchase price alone, D6 seems expensive. But run the math on a yearly basis, and the picture changes.

Cheap blades are disposable. When they dull, you toss them. D6 blades are an asset. Because the material is deep-hardening and structurally consistent, it responds exceptionally well to resharpening. You can restore a D6 blade to “like-new” performance multiple times.

For high-volume operations—especially those cutting difficult multi-layer composites or abrasive recycled papers—the math is simple. Fewer blade changes mean less machine downtime. Higher resharpening potential means a longer total lifecycle. You effectively stop paying for “downtime labor” and start paying for “uptime performance.”

4. Mining: Where D6 Wins (And Fails)

Mining equipment breaks down in two ways. Some parts fail from constant grinding. Others crack from sudden hits. D6 steel handles the first problem well. The second problem? It fails hard.

D6 gives 3-4 times better wear resistance than standard low-alloy tool steels. Hardness reaches 54-61 HRC after proper heat treatment. This makes it perfect for friction-heavy parts that wear over time. But impact strength sits at just 30-50 J. One hard shock can crack what months of grinding couldn’t touch.

4.1. Best Spots for D6

D6 works best in steady-wear applications without impact loads. Wear liners take constant grinding from moving ore. They stay under steady pressure without sudden shocks. D6 keeps its shape through this abuse.

Compaction dies work the same way. Controlled pressure forms materials over time. Guide components slide against moving parts for hours. Wear plates protect equipment from rubbing contact. Scraper blades cut through material in steady motion. All these parts face friction and abrasion. None deal with hammering forces.

Calibration and forming dies need D6’s size stability. The steel holds precise shape under steady, controlled loading. Your parts stay within tolerance through thousands of cycles.

4.2. The Brittleness Risk

D6’s carbide network stops grinding wear. Those same hard carbides make the steel brittle. Edges chip under impact. Cracks form at sharp corners where stress builds up. Positioning pins snap. Vent holes become crack starting points during high-pressure cycles.

Thick sections above 100mm stay hard all the way through. D6 beats D3 steel here. However, full-through hardness also means brittleness extends through the entire section.The core stays just as fragile as the surface.

Design choices matter a lot. Sharp corners act as stress traps. You must add a 2-3mm radius at all internal corners. Skip this step and cracks will start there. No exceptions.

4.3. When to Switch Steels

Crusher hammer heads slam into rock over and over. Drilling tools break through stone with shock loading. Impact-driven parts take hard hits every cycle. D6 fails at all these jobs.

S-series shock-resistant steels handle fast pressure spikes better. They give up some wear resistance for much higher toughness. Impact strength jumps well above D6’s 30-50 J range. Hardness drops but the material flexes instead of cracking.

| Selection Factor | D6 Steel | S-Series Steels |

|---|---|---|

| Best loading type | Grinding, friction, scraping | Shock, impact, pressure spikes |

| Hardness level | 54-61 HRC | Lower, more flexible |

| Wear resistance | 3-4x baseline steels | Adequate but reduced |

| Impact rating | 30-50 J (very poor) | Much higher |

4. 4 Repair Realities

D6 needs oil quenching with tight process control. This keeps size changes minimal. Air-hardening types reduce leftover stress. They work better for deep cavities and thin sections.

Machinability sits at 60%. The carbides and hardness make cutting difficult. Machine D6 in its soft state at HB 225 hardness. This cuts manufacturing costs by 30-40% compared to machining after hardening.

Never attempt weld repairs on D6. Weldability is poor. The steel cracks during welding almost every time. A cracked D6 die gets replaced. You can’t fix it. Budget for complete replacement instead of repair costs.

Match your steel to your loading conditions. Continuous abrasion? D6 performs well. Shock and impact? Switch to S-series right away. Respect these metal limits and your mining applications will run far more reliably.

5. Going Further: Surface Enhancements

In high-abrasion, non-impact applications, heat treatment alone does not fully unlock D6’s wear potential.

Surface enhancement techniques push wear resistance and tool life past standard heat-treated limits. These methods target specific failures that grinding and friction create over time.

Cryogenic treatment works best for D6 steel. Cool the material down to -185°C for 20-40 hours after initial heat treatment. This process converts retained austenite into martensite. It also spreads carbides throughout the steel structure.

The performance gains are measurable. Wear resistance jumps 140-248% compared to conventional heat treatment alone. Tests under 3.1-5.1 kg loads at 1.5 m/s sliding speed confirm these numbers. Shallow cryogenic treatment delivers 100-150% improvement over standard methods.

5.1. Is It Worth the Cost?

Not every D6 application needs extra treatment. The process adds cost and manufacturing time. Run a cost analysis first. Surface enhancement makes financial sense in these cases:

- Tool downtime costs exceed $500 per hour

- Part replacement happens more than twice per month

- Tool changes require extensive machine setup

- Production volumes justify the upfront investment

Paper cutting operations see strong returns from cryogenic treatment. Blade life extends by 2-3 times. Fewer mid-roll blade changes mean less wasted material and production time. High-volume facilities processing coated papers or multi-layer composites benefit most.

5.2. Coating Strategies for Maximum Life

- Choose the Right Shield

Use PVD coatings like Titanium Nitride (TiN) or TiAlN. They drastically cut friction on parts that slide constantly against other materials. - Adhesion Beats Hardness

A hard coating is useless if it flakes off. Focus on bonding strength. Always test adhesion in your specific operating environment before running full production. - Prep the Surface

D6’s high carbide content creates a naturally rough surface. You must polish the substrate to below 0.4 Ra before coating. Skip this, and adhesion strength drops by over 40%. - The “Combo” Effect

For mining wear plates, don’t settle for just one method. Use cryogenic treatment first, then apply PVD coating. This combination pushes service life 3–4 times beyond standard limits.

6. The Bottom Line: Costs & Supply

D6 steel has a higher price tag than basic tool steels. You pay about 30–50% more at the start. Look at the total ownership cost, though. That price gap doesn’t just close. It flips in your favor. Tools last 3-4 times longer than standard alloy options. So, you don’t just buy steel. You buy production time.

6.1. The Real Lifecycle Cost

Why do high-volume manufacturers switch to D6? Check the annual math for a typical high-wear component. Think paper slitters or mold liners. You won’t save on the blade price itself. The real savings come from killing downtime.

| Cost Factor | Standard Tool Steel | D6 Tool Steel |

|---|---|---|

| Initial Part Cost | $100 (Baseline) | $150 (Higher upfront) |

| Service Life | 1 Month | 3.5 Months |

| Annual Replacements | 12 times / year | ~3.5 times / year |

| Downtime Cost (@$200/hr labor & lost prod) |

$2,400 (12 stops) | $700 (3.5 stops) |

| TOTAL ANNUAL COST | $3,600 | $1,225 (Save ~65%) |

High-volume manufacturers get the best returns. You swap tools roughly four times a year. Compare that to twelve times. Labor costs for changeovers drop. Your production runs smooth, and those constant stops vanish. Do the math. The downtime costs strictly outweigh savings from cheaper grades.

6.2. Supply Chain & Standards

Suppliers maintain steady production. Expect 2,000 tons per month. Lead time sits around one month for annealed material. D6 steel fits large operations well. Just plan your orders regularly.

Standard delivery meets ASTM requirements. Material arrives with hardness at or below 255 HBS (annealed). Also, the chemical makeup stays precise:

- Carbon: 2.00-2.20%

- Chromium: 11.50-12.50%

- Tungsten: 0.60-0.90%

In practice, At FCS Steel Factory, we use LF + VD melting followed by forging to keep monthly output stable at over 2,000 tons.

This process control allows us to deliver D6 in consistent batches, with uniform carbide distribution maintained even in sections thicker than 100 mm.

Conclusion

D6 steel works best when it is used for the right kind of wear, not just for high hardness numbers. In continuous abrasion applications like paper cutting or steady sliding wear parts, the base material is only the starting point.

Proper heat treatment, cryogenic processing, or surface coatings are what turn D6 into a long-life tool.

The real savings come from reduced downtime and predictable wear, not from a lower purchase price.

Before choosing D6, focus on how the tool actually fails—abrasion, contact pressure, section thickness, and impact risk. Getting this match right saves far more than choosing a cheaper grade.