by allen | Oct 23, 2025 | cold work tool steel, Stainless Steel

In the world of Japanese-inspired knife making—whether we’re talking chef’s gyutōs in the kitchen, outdoor fixed-blades for camping, or utility knives made in the Japanese style—the choice of steel is one of the most important decisions that both manufacturers and...

by allen | Oct 21, 2025 | cold work tool steel, Stainless Steel

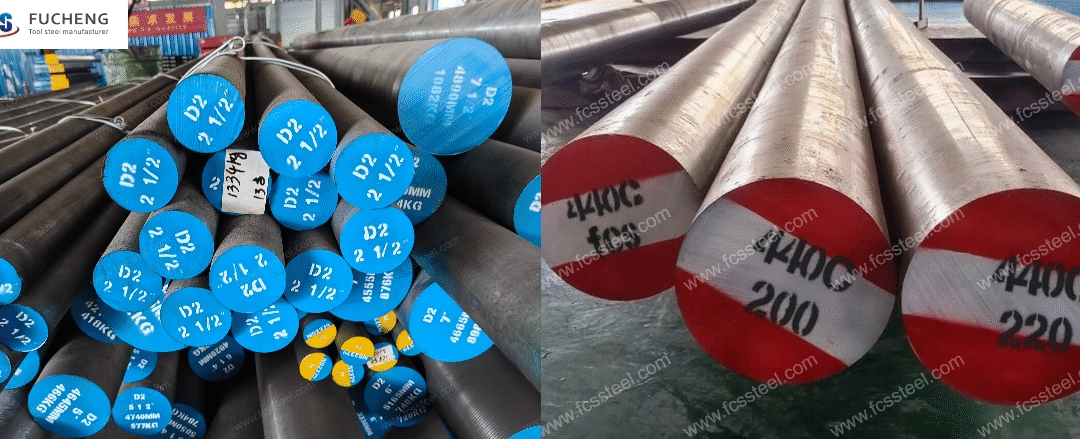

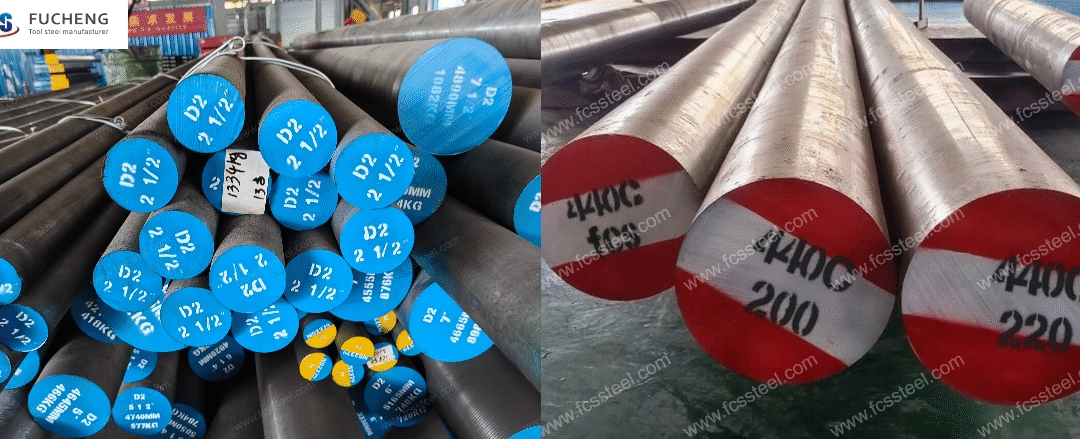

Why do some tool steels keep a sharp edge for years while others fight off rust better? D2 and 440C show this trade-off. One excels at wear resistance. The other wins at stopping corrosion. I’ve seen manufacturers pick the wrong steel and face early tool failure...

by allen | Oct 20, 2025 | cold work tool steel

Germany is home to one of the world’s most sophisticated mould and die industries, known for precision engineering, automated production, and strict metallurgical standards. Within this ecosystem, the selection of tool steel plays a critical role — especially in cold...

by allen | Oct 17, 2025 | cold work tool steel

The American high-speed cutting industry stands as one of the most advanced in the world, driven by precision machining, aerospace manufacturing, and die tooling applications. Among the materials that define tool performance, l and M2 steel are two of the most...

by allen | Oct 14, 2025 | cold work tool steel

Ever wonder why D2 tool steel prices jump 9% in one country but stay flat in another? In 2025, the global market for this material is far from uniform. China ships it at $2,450 per ton. Germany’s buyers pay over $3,100 for the same grade. I’ve noticed...

by allen | Oct 14, 2025 | cold work tool steel

I’ve seen some mold makers get 40% more life from their D2 steel tools. Others face edge chipping and early wear. Why the difference? It’s not about the steel itself. It’s about how you treat it, coat it, and use it. Nordic makers have worked on D2...