Introduction:

Japan’s electronics manufacturing sector operates within razor-thin tolerances, backed by the globally rigorous JIS G4404 standards. When a single micron separates perfection from failure in millions of stamping cycles, material choice isn’t just a preference—it’s a critical engineering decision.

While many tool steels compete, D6 tool steel (marketed as SKD2 steel in Japan) stands out. It meets the uncompromising demands for dimensional stability and wear resistance mandated by top Japanese facilities. This guide explores why D6/SKD2 dominates electronics stamping, detailing its metallurgical advantages and strict quality benchmarks.

1. Core Properties for Electronics Stamping

D6 tool steel’s makeup creates a material built for tough stamping work. The chemistry determines how it performs in high-volume electronics production.

Chemical Performance

- Carbon (2.0–2.2%): Pushes hardness to 55–62 HRC. This gives you strong wear resistance for delicate parts.

- Chromium (11.5–12.5%): Makes it a high-chromium steel. It resists corrosion and forms the carbide network you need for durability.

- Tungsten (0.6–0.9%) & Molybdenum: These stabilizers lock carbides in place. They stop the die from deforming under heavy loads.

- Molybdenumworks with carbon and chromium. This combo strengthens resistance to plastic bending. Your die edges keep their shape under repeated high-pressure forming.

Real-World Stamping Metrics

Compressive strength exceeds 2,500 MPa after heat treatment, preventing plastic collapse under peak stamping loads.Your dies won’t collapse. Parts stay accurate through runs exceeding 500,000 cycles. With an elastic modulus of 194 GPa, stiffness is excellent. Tool bending stays small, so your first stamped part matches the millionth one.

Heat Treatment for Locked Performance

D6 needs a two-stage process: oil quenching, then tempering at 300°C. This keeps hardness above 58 HRC. It stops delayed cracks during use. The tempered structure hardens through sections up to Ø42 mm. Surface-to-core variation is just 1.5 HRC.

Controlled hardening reduce quench distortion compared with low-alloy tool steels.

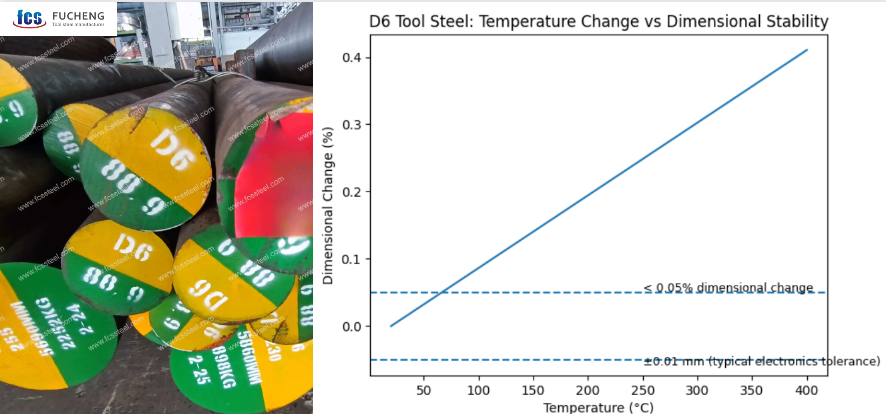

2. Mastering Dimensional Stability

Electronics stamping needs tight tolerances. Die movement can’t happen. After tempering, D6 steel typically shows a linear dimensional change of only 5–15 μm per 100 mm under controlled heat treatment conditions. You’re making connector pins? Positional accuracy stays within ±0.01mm across all cavities.

Table. Dimensional Stability of D6 in Precision Stamping Dies

| Stability Factor | D6 Technical Value | Why It Matters in Electronics Stamping |

|---|---|---|

| Thermal expansion (21–400 °C) | 10.8 × 10⁻⁶ /°C | Enables accurate cavity offset calculation during die design. |

| Expansion in precision tooling | 10.5 × 10⁻⁶ /°C | Maintains micron-level tolerances in fine-feature dies. |

| Compressive strength | ≈1300 MPa (heat treated) | Resists plastic deformation under peak stamping loads. |

| Elastic modulus (typical) | ≈194 GPa | Limits elastic deflection during high-speed stamping cycles. |

| Multi-cavity dimensional control | Stable across cavities | Reduces cavity-to-cavity dimensional variation. |

| Tungsten content | 0.6–0.8% W | Improves carbide stability and minimizes hardening distortion. |

| Quench response | Uniform | Ensures consistent cavity size after heat treatment. |

| Tempering method | Two-stage tempering | Relieves residual stress and locks in die geometry. |

| Typical tempering temperature | ~300 °C | Prevents dimensional creep during service. |

| Working hardness | 58–64 HRC | Supports long-term shape retention under load. |

Summary

Stable dimensions are not just a quality advantage—they are the foundation of long tool life.

Because D6 tool steel shows predictable thermal expansion, high elastic stiffness, and minimal heat-treatment distortion, die geometry remains unchanged during long, high-speed stamping runs. This stability prevents uneven contact, localized overload, and premature edge wear.

As a result, stamping dies maintain correct clearances longer, produce consistent parts without frequent adjustment, and achieve significantly longer service life compared with steels that suffer from thermal drift or hardening distortion.

3. Superior Wear Resistance

Comparison: D6 vs D2 vs A2

| Wear-Related Factor | D6 Tool Steel | D2 Tool Steel | A2 Tool Steel |

|---|---|---|---|

| Carbon content (carbide potential) | 2.0–2.2% | ~1.4–1.6% | ~1.0% |

| Effective carbide volume | Very high | High | Moderate |

| Dominant carbide type | Cr-rich carbides | Cr-rich carbides | Fewer mixed carbides |

| Carbide stability under wear | High (W-stabilized) | Medium | Lower |

| Resistance to abrasive wear | Highest | High | Moderate |

| Resistance to adhesive wear | High | Medium | Lower |

| Working hardness range | 58–64 HRC | 58–62 HRC | 56–60 HRC |

Why D6 Outperforms at the Same Hardness

1. Higher carbide volume:

D6 contains significantly more hard carbides than D2 or A2, so wear is absorbed by carbides rather than the steel matrix at the same hardness.

2. Tungsten-stabilized carbides:

Tungsten refines and locks carbides in place, reducing pull-out and slowing wear during long, high-cycle runs.

3. Wear-first alloy design:

Unlike A2, which sacrifices wear resistance for toughness, D6 is engineered to maximize carbide content for abrasive and adhesive wear resistance.

Engineer Takeaway

At equal hardness, D6 outperforms D2 and A2 in wear resistance because carbide volume and stability—not hardness—dominate real-world wear behavior.

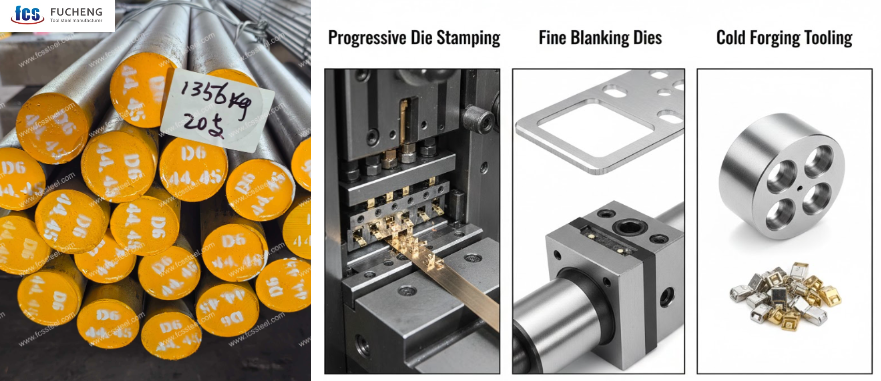

4. Critical Electronics Applications

Japanese electronics makers use D6 steel for tough stamping jobs. These jobs need both precision and high output. D6’s carbide-rich structure solves problems that break softer tool materials.

1. Progressive Die Stamping

Use this for connector terminals in multi-station setups. It runs at 58–64 HRC. Tool life beats D2 steel by 40%. Plus, it maintains tolerances for 300,000+ cycles, even on abrasive phosphor bronze strips.

2. Fine Blanking Dies

This suits stainless lead frames that need clean edges. D6 gives you 1320 MPa compressive strength. That handles triple-action forces easily. It stays sharp at 60–62 HRC. So, you can skip deburring.

3. Cold Forging Tooling

Shape microswitch contacts under high pressure. Each die handles 100,000+ pieces at 58–60 HRC. You get 3–4x longer life than low-alloy steels thanks to the carbide structure. It works great in heavy-load setups.

Hardness Range for Maximum Tool Life

Good heat treatment brings D6 to 54–61 HRC. Peak performance hits 55–62 HRC under controlled conditions. Electronics stamping dies need specific hardness ranges for different jobs:

- Stamping dies for aluminum extrusion punches: 60–62 HRC

- Drawing dies (concave forms) needing extreme wear resistance: 62–64 HRC

- Forming tools for hard materials: 58–64 HRC range

Higher hardness extends tool life. But you get a trade-off: toughness drops and brittleness rises. D6 works best where impact loading stays low. Steady stamping pressure suits it well. Shock loads? That’s where D6 falls short.

Real-World Performance: D2 vs. D6 Case Study

In a production run for phosphor bronze terminals, standard D2 punches developed burrs (>0.03mm) after just 180,000 cycles. By switching to D6, the maintenance interval jumped to 310,000 cycles—a 72% increase. This simple change eliminated four hours of downtime per week.

5. Surface Treatment Enhancements

Not every die needs extra treatment. D6 is tough, but some jobs are tougher. Use this guide to decide when your tool needs that extra boost:

| Stamping Scenario | Is Surface Treatment Necessary? | Why Do It? (Key Benefit) |

|---|---|---|

| General Electronics Stamping (Phosphor Bronze, Brass, Aluminum) | ❌ Not Required | D6’s native hardness (58–62 HRC) provides sufficient wear resistance for standard, non-abrasive materials. |

| High-Speed / High-Volume Runs (Long-run production) | ⚠️ Highly Suggested | Reduces adhesive wear and edge rounding, helping maintain sharp cutting edges and minimize downtime. |

| Hard or “Sticky” Materials (Stainless steel, plated strips) | ✅ Mandatory | Prevents galling and material pickup on punches, avoiding surface scoring and premature die failure. |

| Micro-Terminals & Fine Features (Precision multi-cavity dies) | ✅ Recommended | Improves edge stability and dimensional consistency when tolerances are measured in microns. |

Advanced Treatment Methods

- Cryogenic Processing: Cool the steel below -80°C after quenching. This converts retained austenite into martensite, locking in dimensional stability.

- Fiber Laser Surface Hardening: Use a high-energy laser to harden only the cutting edges (up to 64 HRC). The core keeps its toughness, preventing warp.

6. Cost & ROI Analysis

D6 (SKD2) costs more upfront than standard D2. However, the return on investment (ROI) makes sense for high-volume production. Here is where you find the value:

Production Volume Breakeven Points

- Tool Longevity: D6 runs 300,000+ cycles before edge wear stops you. Standard materials only last 180,000 cycles. That gives you a 67% increase in tool life.

- The Breakeven Threshold: Do tool replacement costs exceed USD 50,000 annually? That creates positive ROI. Run over 180,000 cycles/tool? You see immediate payback.

- Real Savings: A high-volume connector line switched to D6. They saved USD 75,000+ per year. The payback period took just 1–2 years.

Material Grade Economics

- ESR Premium: Electroslag Remelting (ESR) grade D6 costs 30–40% more. But it cuts non-metallic inclusions by >50%.

- Why Pay It? Need tolerances tighter than ±0.001mm? Reduced scrap rates justify this cost.

7. JIS G4404 Standards & Quality Assurance (SKD2)

In Japan, D6 is designated as SKD2. Unlike generic specs, SKD2 enforces tight controls. Use this reference table to verify incoming steel:

| Parameter | JIS G4404 (SKD2) Target | Why Check This? |

|---|---|---|

| Carbon Content | 2.00 – 2.30% | Verify the steel reaches the high-carbon range required for maximum wear resistance and carbide formation. |

| Tungsten (W) | 0.60 – 0.80% | Critical for dimensional stability and hot hardness; this element is absent in D3 steel. |

| Hardness (Annealed) | ≤ 255 HB (≈ ≤ 46 HRC) | Ensures the material is soft enough for complex machining, EDM, and fine feature processing. |

Incoming Quality Control (IQC) Protocol

- Ultrasonic Testing (UT): Mandatory for blocks >50mm. Look for internal voids that cause cracking.

- Microstructure Analysis: Check for “carbide clumping.” Clusters cause edge chipping on delicate pins.

- Inclusion Levels: specify ESR grades for micro-connectors to boost impact toughness.

Conclusion

Japanese electronics manufacturing demands extreme precision. D6 tool steel (commonly known as SKD2) meets this requirement by maintaining tight dimensional control in stamping dies. Stable geometry, predictable behavior, and strong wear resistance ensure consistent output across high-volume production, even at micron-level tolerances.

Manufacturers choose D6 for three reasons: reliability in continuous stamping, compliance with strict Japanese quality standards, and lower total cost over time. Though the initial investment is higher, D6 delivers long-term value where precision cannot be compromised.